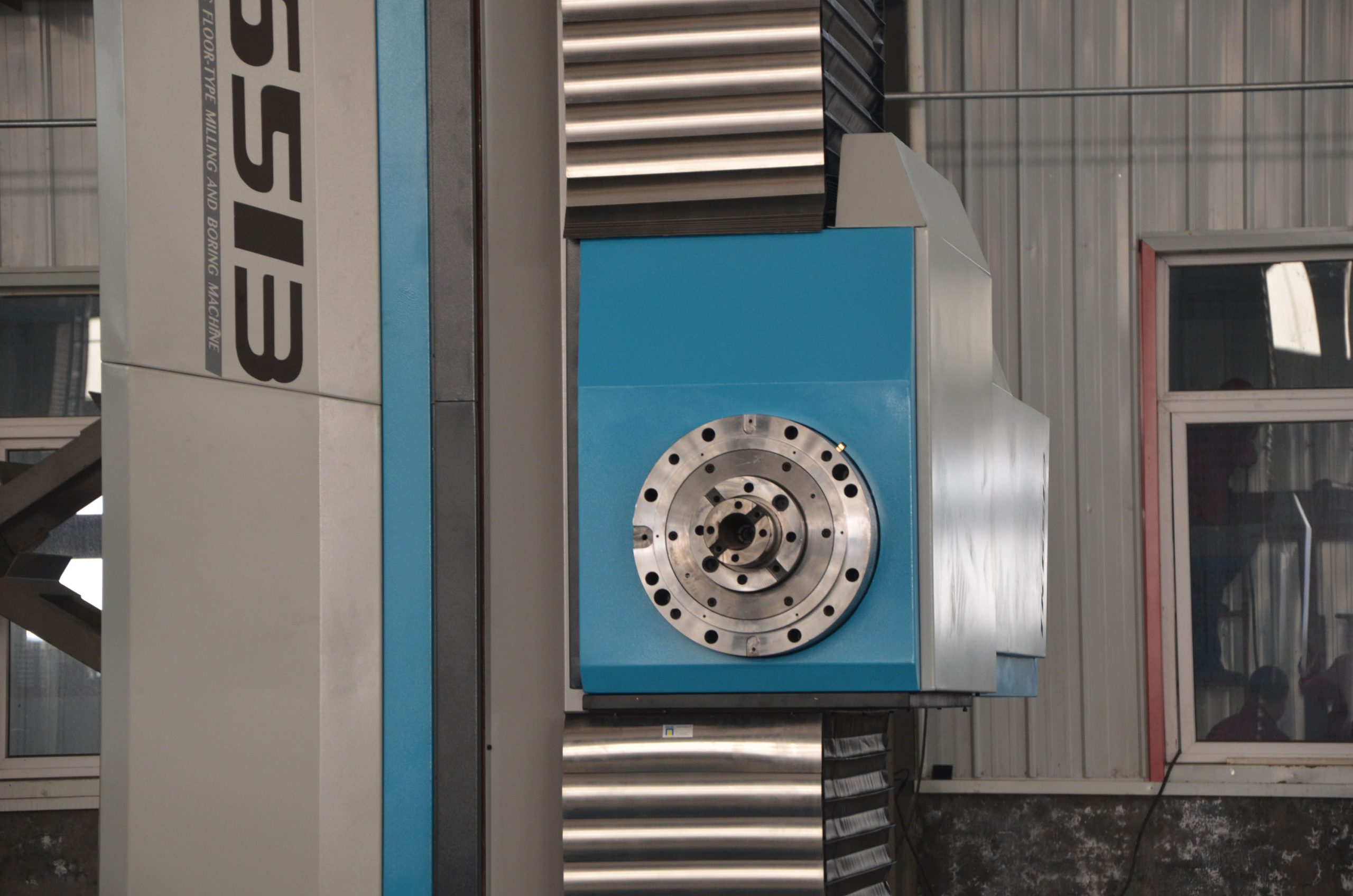

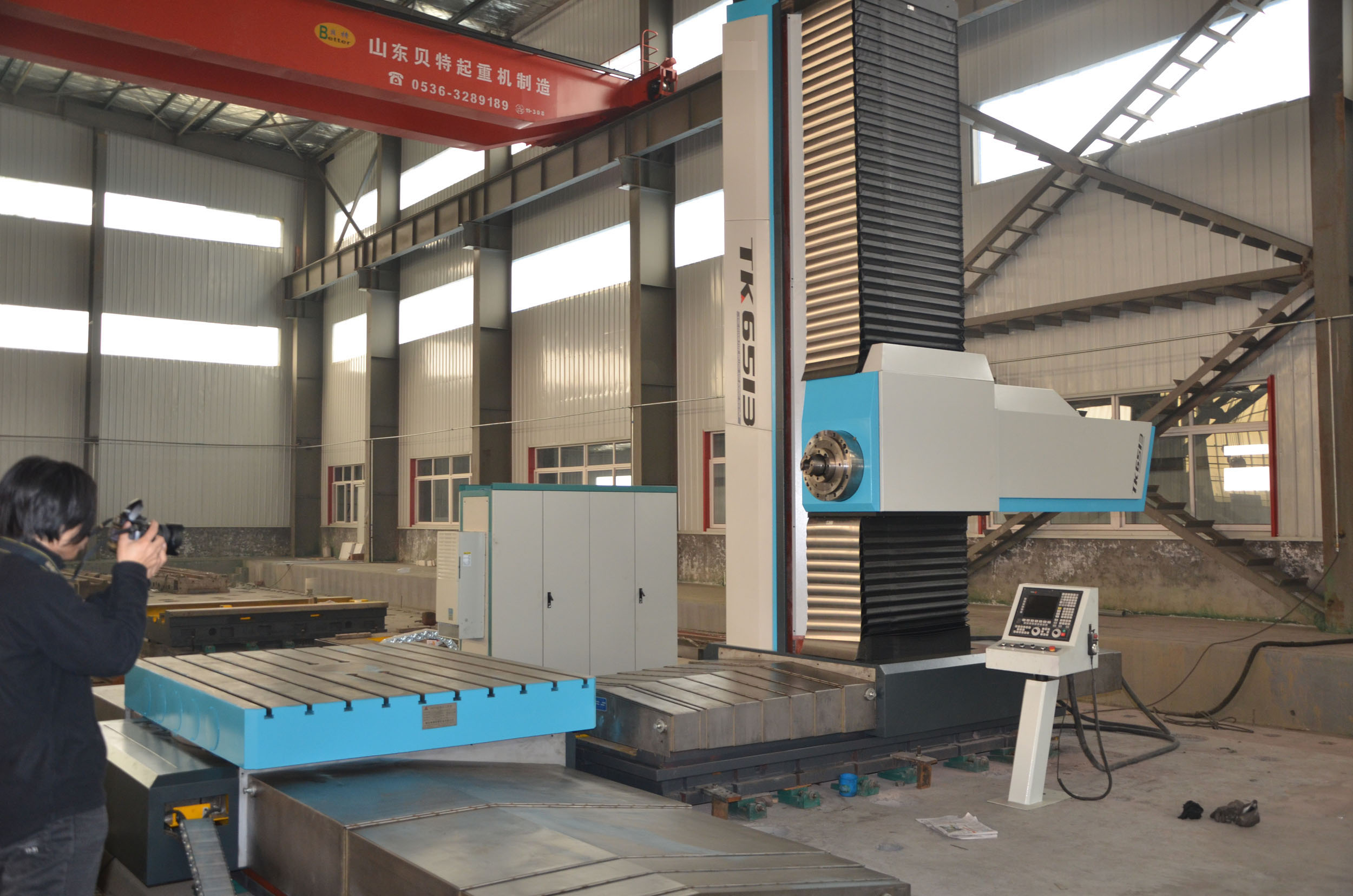

TK6513 Boring mills

Planner type

Description

TK6513 series CNC boring mills is the planner type boring series The machine can complete boring, milling, drilling, reaming and tapping etc. machining procedures with once clamping. Optional equipped with right angle milling head,universal milling head, rotary table and other optional accessories, it can do heptahedron machining.

control Axis

Basic configuration of 5 feed axis and one spindle;Each coordinate axis defined as follows:

X axis:Worktable transverse travel

Y axis:Headstock move up and down along the vertical column;

Z axis: Boring spindle front-back travel;

B axis: NC rotary table rotary indexing

| No. | Specification | unit | Values and notes |

| CNC horizontal boring and milling machine | |||

| 1 | Spindle diameter | mm | φ130 |

| 2 | Spindle top diameter | mm | φ221.44 |

| 3 | Taper | ISO 50( JT50 7:24 ) | |

| 4 | Blindrivet model | D50 DIN69872 | |

| 5 | Power of main motor | Kw | 30 |

| 6 | Spindle Speed | r/min | 2-1800r/min |

| 7 | Max. torque of spindle | N.m | 3136 |

| 8 | Max. axial resistance of spindle | N | 31360 |

| 9 | Worktable size | mm | 1800*1600 |

| 10 | Max.loading on table | Kg | 8000 |

| 11 | Worktable transversal travel (X axis) | mm | 3000 |

| 12 | Headstock vertical travel(Y axis) | mm | 2000 |

| 13 | Column travel l(Z axis) | mm | 1500 |

| 14 | Spindle travel (W axis) | mm | 700 |

| 16 | Rotary speed of worktable(B axis) | ° | 360 |

| 17 | The width of T-slot and number | mm | 22 |

| 18 | Min .distance from spindle top to table center | mm | 100(spindle extend) |

| 19 | Distance from spindle center to the table | mm | 2375 |

| 20 | Max. Feeding speed (X axis) | mm/min | stepless,1-5000mm/min |

| 21 | Max. Feeding speed (Y axis) | mm/min | stepless,1-5000mm/min |

| 22 | Max. Feeding speed (Z axis) | mm/min | stepless,1-5000mm/min |

| 23 | Max. Feeding speed ( W axis) | mm/min | stepless,1-5000mm/min |

| 24 | B axis | r/min | 0~1 |

| 25 | System | SIEMENS828/FANUC OI | |

| 26 | Max. rapid feeding speed (X、Y、Z axis) | mm/min | 5000 |

| 28 | Spindle cooling | 20bar | |

| 29 | Protective door plate | CE Nor |

Boring mill-1 catalog download

What are the main application areas of TK6513 boring machine? In which industries and applications are this type of boring machine often used?

The TK6513 boring machine can be used in multiple application fields and industries.

It is often used in the production of heavy machinery and equipment, such as engineering machinery, mining equipment, and agricultural machinery, for boring and processing large components such as engine blocks and frames.

It can also be used in the shipbuilding industry to drill and process various components of ships, including engine blocks, transmission shafts, and other large components.

The TK6513 boring machine can also be used in the aerospace industry for precision boring and machining of aircraft landing gear, turbine engine parts and structural components.

The automotive industry is naturally indispensable and is generally used for processing engine cylinder blocks, cylinder heads, and transmission components to ensure the accuracy and quality of these key components.

In addition, the energy sector can be used to manufacture components such as gas and steam turbine parts, as well as components for hydroelectric and wind power generation.

Various general manufacturing environments that require large precision boring machines, such as the production of industrial pumps and compressors.

The commonly seen infrastructure and buildings also rely on boring machines, which can be used in the construction and infrastructure departments to process components used in large-scale infrastructure projects, such as bridges and tunnels.

WEISH CNC MASTER provides professional high-quality TK6513 boring machines.

What are the main technical specifications and performance characteristics of this boring machine?

Technical Specifications:

1. Max. Turning Diameter: 6500 mm

2. Max. Boring Length : 2000 mm

3. Max. Turning Height : 1400 mm

4. Spindle Speeds: 2 to 400 rpm

5. Feed Rates: 0.015 to 1.450 mm/rev.

6. Longitudinal Traverse: 3000 mm

7. Spindle Torque: 1050 Nm

8. Spindle Motor: 30 kW

Performance Characteristics:

1. High precision and accuracy

2. Low vibration and noise levels

3. High cutting speed thanks to a powerful spindle motor

4. Ability to work with heavy and long parts

5. Robust design and construction for increased durability

6. Multi-function control panel for intuitive operation

7. Automatic cut-off and central lubrication systems for greater efficiency.

What are the automation and CNC functions of TK6513 boring machine?

The TK6513 boring machine is capable of both automated and CNC functions. Automation functions include automated loading and unloading of material, as well as automated functional equalization. The CNC functions of the TK6513 include advanced tooling geometry, motion control, and spindle speed control. The machine can also be programmed for optimal performance through the CNC system. Additionally, the TK6513 machine can be operated either manually or in an automated mode, depending on your needs and preferences.

What accessories or customization options does the manufacturer provide to meet the special needs or application requirements of different users?

WEISH CNC MASTER may provide different cutting tools to achieve various cutting depths, adjustable guides to improve accuracy, and larger tables for precise guidance. They may also offer specific attachments to accommodate different materials, custom settings for specific applications, as well as additional safety features. They could also offer optional accessories that would make the operation easier and faster, such as dust collection systems, depth setting stops, feed rate controls, automated loading/unloading functions, and protective guards.

TAGS: CNC boring mill

You must be logged in to post a review.

Reviews

There are no reviews yet.