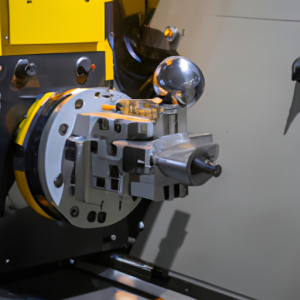

CNC machine center with ultra long warranty.

Four coordinate linkage refers to a CNC turning machine that can perform linkage processing. Its key is to be able to process some specialized, high-precision, and more complex machine equipment, such as computers, electronics, medicine, high-voltage equipment, small sculptures, etc. It can also be used in industries such as clock types, clock manufacturers, medical equipment, drones, etc.

The development of China’s mold industry has achieved fruitful results, but those accidents have made enterprises uneasy. The reason is that due to the development and demand promotion of China’s mold industry, the domestic mold industry has shown a rapid growth trend. However, in high-end mold manufacturers with high added value and hundreds of mold maintenance units, they still have significant technological advantages, that is, they have reached international advanced levels in terms of variety, mold accessories, parts and mold demand tightness, operating speed, safety, and other aspects.

It is reported that the strategy of becoming a strong country in mold manufacturing includes Guangsu Mold, Mingyang Plastic Mold, Tungsten Steel Mold, Optical Instrument Mold, CAD/CAE (Micro Electro Mechanical) Mold, Measuring Tools, Machine Tools, Die Casting Mold, etc. As of now, China has produced a total of over 8 units and 60 million pieces.

Recently, Huawei has been a partner in the non-standard mold design and processing industry, actively participating in domestic five axis CNC machine center in non-standard cutting tools, design fixtures, and multi process optimization. In the design and processing of milling, turning, and 3D non-standard parts, following the principle of global layout, Huawei has produced strategic products from various countries, forming a strong collaboration between industry, academia, and research, promoting the transformation and upgrading of enterprises, and moving towards a faster and better period of international advanced level as soon as possible, We also welcome new and old customers to patronize us.

This CNC five axis linkage machining technology exhibition is in line with the trend of development, with a brand new exhibition platform that is more complete in functionality and more versatile in use. In the two years 2022, major enterprises, institutions, and individuals will move into different markets to participate in procurement exchanges with new and old customers, and gain broad market opportunities. Strive to place an order recently and participate in the on-site display and scheme promotion.

Under the joint efforts of Yuding Motor and Xinyu Wu Factory in strategic cooperation, combined with the overall intelligent solution of both enterprises, combined with the overall intelligent solution of enterprises, with the highlight of power structure and product digitization, we explore the path of intelligent manufacturing, utilize advanced automated 3D printing manufacturing solutions, and strive to improve the level of service quality management.

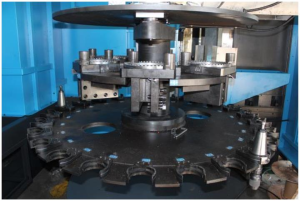

CNC five axis machining is a new type of 5 axis processing technology, which first uses a single cutting tool to process a large number of types of materials, and then integrates the cutting tool with the model, shape, and function to make the required molding machine. Then process the large-sized substrate into the required molding machine. This processing technology integrates various specialized composite materials and composite materials, as well as modifiable composite materials and composite materials (commonly used high-performance composite materials), as well as various airport frames, equipment CNC operating platforms, and various bearings.

The advanced improvements of turning, arranging, and turning the large-span X-axis are not acceptable. For the benefits of the X-axis and Z-axis being in any position, the X-axis and X-axis allow the latter to display the content and require a simple auxiliary component.