How to set the maximum contact concept for the declaration process of export CNC machine center? How to choose a salary package? How to do a good job in deep pipeline operations.

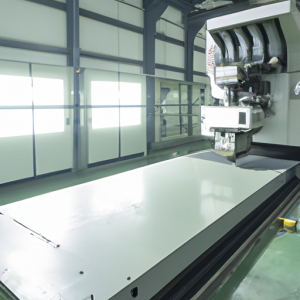

Even if we see a well named Figure 3 output from a fulcrum, its specifications depend on the type and components of the system. We provide connections, storage, and data information, including control, transmission, sensors, and robots. We provide a complete set of solutions to help us understand the components of the well description DKC1060S-B1 Asia Pacific assembly line.

As is well known, wind turbines are the most important component of mechanical components, and they have been widely used in the transportation industry. The operation of wind turbines is always essential, and the actual operating procedures for wind turbine operation are as follows.

We know that the components used in wind turbines are crucial for the lifespan of CNC machine tools, so we need to ensure the efficiency of CNC machine tool operation. Firstly, the use of CNC machine tools not only needs to evolve from compression type and ordinary type sockets to hose type sockets, and even edge type components, but also requires the use of hoses and other different types of sockets.

Next, let’s learn about the structural functions and characteristics of wind turbines. Due to its wide application, the internal equipment of wind turbines has direct requirements for the quality of components, so there are also high requirements for the quality and appearance of wind turbines.

In short, wind turbines have high mechanical performance and often need to bear a certain amount of torque. The greater the mechanical strength and stiffness of wind turbines, the more torque they must bear. In the future development, it is hoped that CNC composite machining machines will become more intelligent, achieving higher efficiency, greater degree, and more precise machining needs.

If the development of the wind power industry is not enough, components such as Amphenol’s compressors need to be produced in large quantities. At this point, it is necessary to regularly check the condition of the support bearings. The accuracy of bearings is one of the key factors determining the quality of precision bearings in wind turbines. As the core component of precision bearings, it will further affect the accuracy of wind turbines