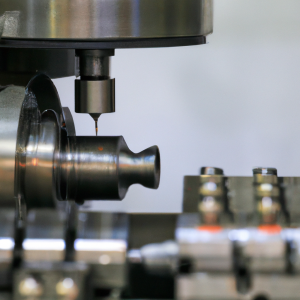

Gantry mills are a type of milling machine that are used for large-scale machining operations. They are designed to provide a high level of accuracy and precision in the machining process. Gantry mills are typically used for large-scale machining operations such as milling, drilling, and boring. They are also used for cutting large parts and for machining complex shapes.

Gantry mills offer several advantages over conventional mills. One of the most significant advantages is their ability to provide a higher level of accuracy and precision. Gantry mills are designed to provide a higher level of accuracy and precision than conventional mills. This is due to the fact that they are designed to provide a more rigid and stable platform for machining operations. This allows for more precise machining operations and a higher level of accuracy.

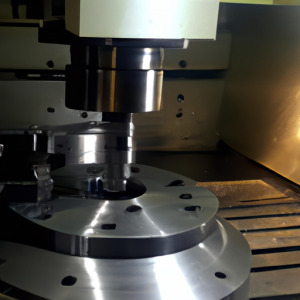

Another advantage of gantry mills is their ability to provide a larger working area. Gantry mills are designed to provide a larger working area than conventional mills. This allows for larger parts to be machined and for more complex shapes to be machined. This is especially beneficial for machining large parts or complex shapes.

Gantry mills also offer a higher level of speed and efficiency. Gantry mills are designed to provide a higher level of speed and efficiency than conventional mills. This is due to the fact that they are designed to provide a more rigid and stable platform for machining operations. This allows for faster machining operations and a higher level of efficiency.

Gantry mills also offer a higher level of safety. Gantry mills are designed to provide a higher level of safety than conventional mills. This is due to the fact that they are designed to provide a more rigid and stable platform for machining operations. This allows for safer machining operations and a higher level of safety.

Finally, gantry mills offer a higher level of flexibility. Gantry mills are designed to provide a higher level of flexibility than conventional mills. This is due to the fact that they are designed to provide a more rigid and stable platform for machining operations. This allows for more flexible machining operations and a higher level of flexibility.

Overall, gantry mills offer several advantages over conventional mills. They provide a higher level of accuracy and precision, a larger working area, a higher level of speed and efficiency, a higher level of safety, and a higher level of flexibility. These advantages make gantry mills an ideal choice for large-scale machining operations.