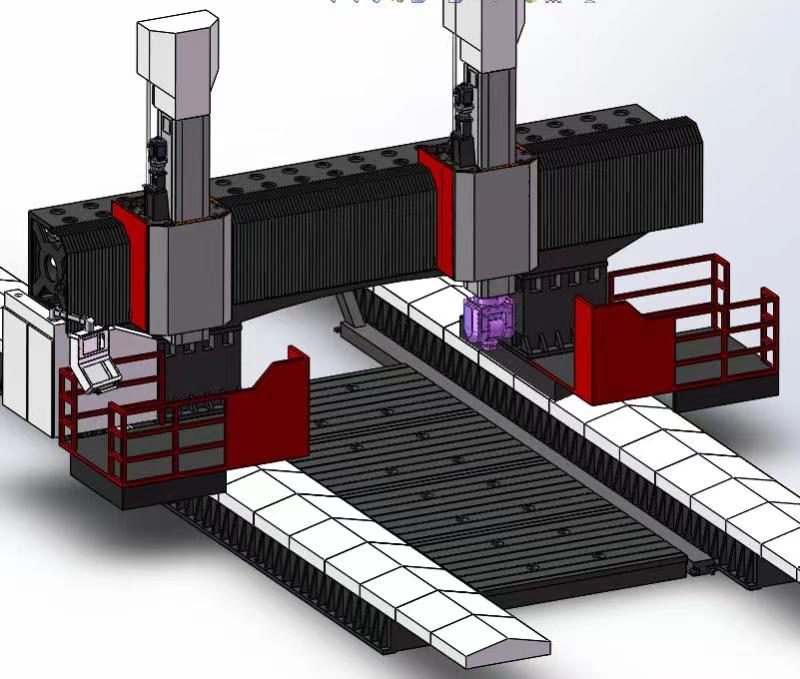

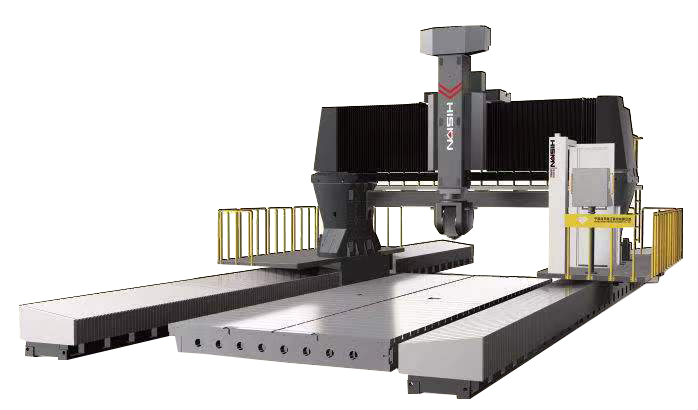

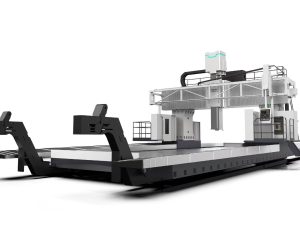

5 axis gantry machining center

We make this type customerized up to our clients

Description

| No | Item | |

| 1 | Table size | 8000 mm×3000 mm |

| 2 | All axis move | X:8600 mm

Y1: 5800 mm Y2: 5800 mm Z1: 1550 mm Z2: 1550 mm |

|

3 |

Table loading | 7000kg/M2

Slot:36×250mm |

| 4 | Axis control | 5 axis linkage working |

| 5 | Distance between spindle end surface and worktable surface | 600~2150 mm |

| 6 | Ram size | 500×500 mm |

| 7 | Between column | 4100 mm |

| 8 | Main spindle | Main spindle:Siemens AC Servo Motor

Motor poser:22/26Kw Max torque:1120Nm Taper:ISO50 BT50 Spindle speed:10~6000RPM Spindle dia:Φ190 mm Spindle taper hole cleaning method:Air Spindle head balance method: nitrogen balance Spindle positioning method: encoder Bearing cooling method: constant temperature oil cooling Bearing lubrication medium: imported FAG grease Bearing lubrication method: Grease |

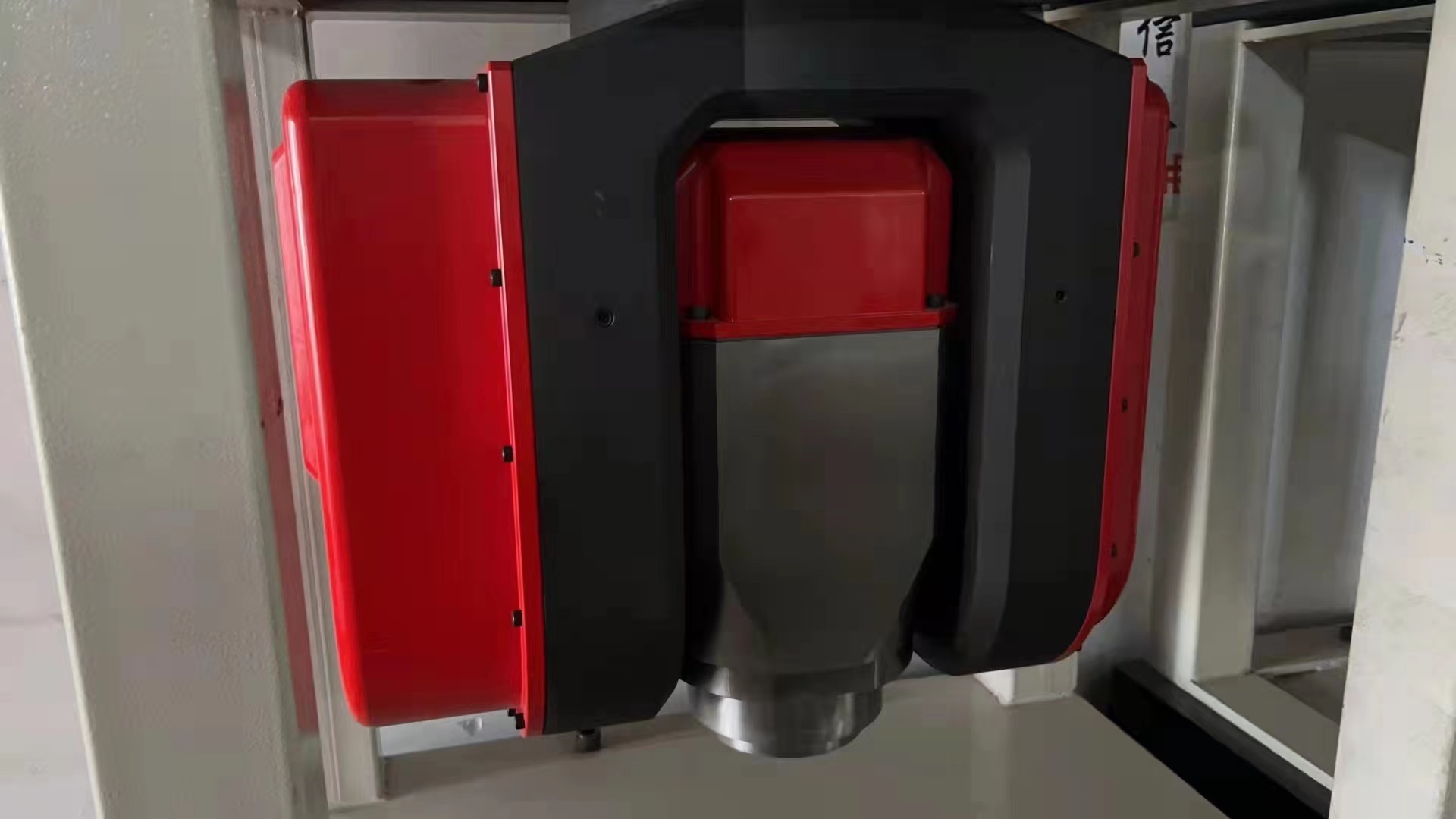

| 9 | 5 axis head | A-axis rated torque: 1060Nm

A-axis hydraulic clamping torque: 4000Nm (60bar) Maximum swing speed of A-axis: 60rpm A-axis rotation angle range: ±110° A-axis encoder type: absolute C-axis rated torque: 1350Nm C-axis hydraulic clamping torque: 4000Nm (60bar) Maximum swing angular speed of C axis: 60rpm C-axis rotation angle range: ±360° C-axis encoder type: absolute Indexing:0.001° Spindle The highest torque of the spindle: 298Nm Maximum spindle speed: 10000rpm ( Adjustable) Spindle rated current: 173.5A Taper:HSK-A100 Lubrication method: grease lubrication |

| 10 | Driven system | Three-axis feed motor: Siemens AC servo motor

X-direction rack and pinion transmission: dual-axis output, dual-motor anti-backlash, four motors Y1-direction screw diameter: φ80mm Y2-direction screw diameter: φ80mm Z1-direction screw diameter: φ63mm Z2-direction screw diameter: φ63mm |

| 11 | Motor power torque | X: 36N.M (four reducers, reduction ratio 1:50)

Y1: 36N.M (precision reducer, reduction ratio 1:4) Y2: 36N.M (precision reducer, reduction ratio 1:4) Z1: 36N.M (brake, precision reducer, reduction ratio 1:3) Z2: 36N.M (brake, precision reducer, reduction ratio 1:3) |

| 12

13

|

Rapid move | X axis: 12 m/min

Y1 axis: 12 m/min Y1 axis: 12 m/min Z1 axis: 10 m/min Z2 axis: 10 m/min |

| 12

13

|

Feed rate

Machine accuracy |

X、Y、Z:1~6000 mm/min |

| positioning accuracy: | ||

| X:0.020mm | ||

| Y1:0.015mm Y2:0.015mm | ||

| Z1:0.015mm Z2:0.015mm | ||

| Re positioning accuracy: | ||

| X:0.015mm | ||

| Y1:0.010mm Y2:0.010mm | ||

| 14 | Z1:0.010mm Z2:0.010mm | |

| 15 | Three-axis Linear | X: P grade roller 65mm (four linear rails)

Y: P grade roller 65mm (two linear rails) Z: Four-sided hard rail |

| 16 | Electrical cabinet | The electrical control box is sealed and equipped with an electrical cabinet empty |

| 17 | Lubricant distribution method | Quantitative allocation |

| 18 | Lubricating oil flow | 150ml/min |

| 19 | Maximum pressure of coolant | 0.6MPa |

| 20 | Maximum coolant flow | 50 L/min |

| 21 | 0.6MPa | |

| 22 | Available air pressure range | 0.45~0.6MPa |

| 23 | Air flow | 0.6~0.9 m3/min |

| 24 | Total power | 180KVA |

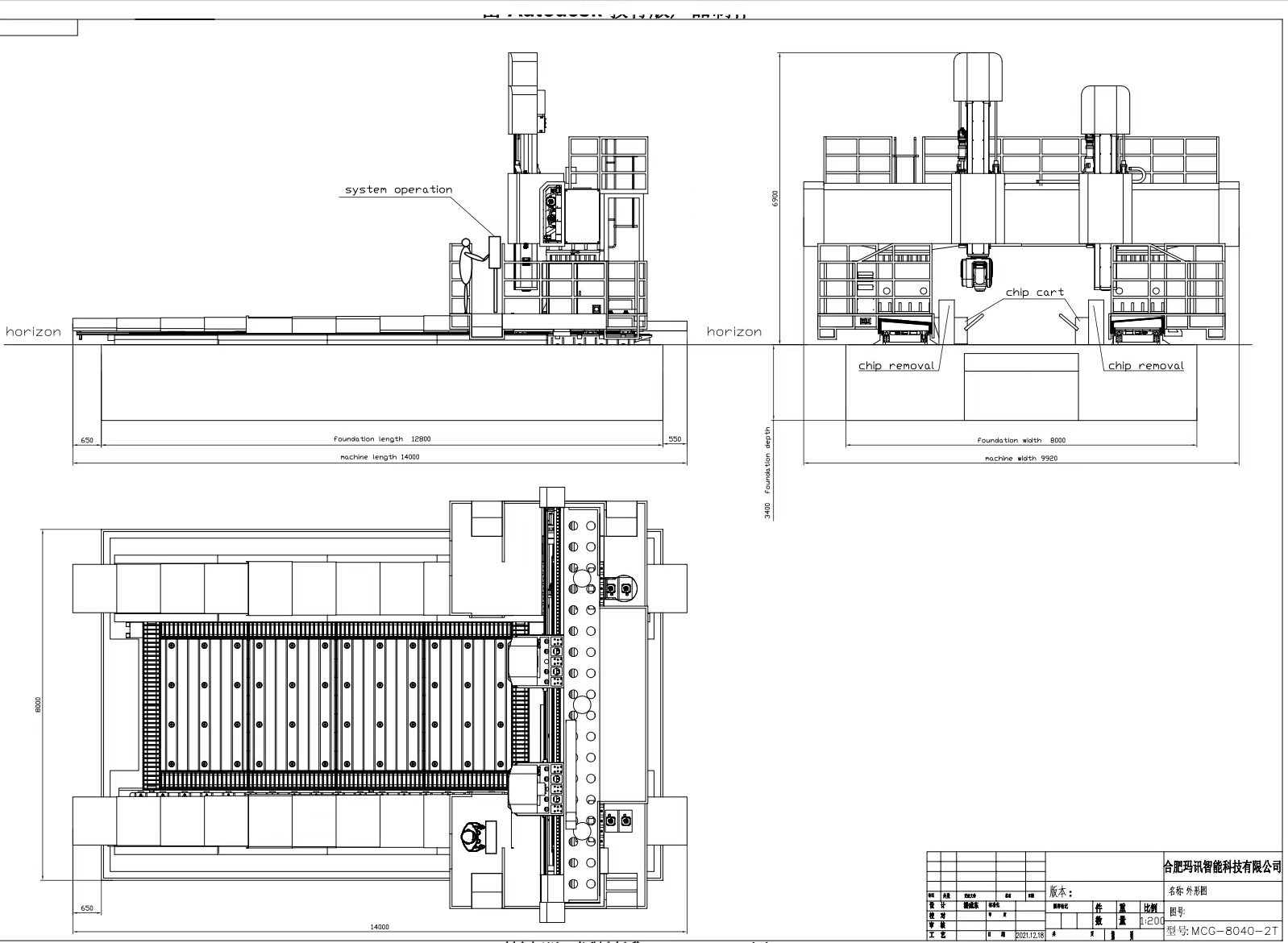

| 25 | Over size | 15500×10000×8000 |

| 26 |

Tags: 5 Axis Gantry Machining Center

What are the unique processing capabilities and advantages of a 5 axis gantry machining center compared to a 3-axis or 4-axis machine?

5-axis gantry machining center offers unique processing capabilities and advantages compared to 3-axis or 4-axis machines by providing enhanced versatility for machining complex geometries, reducing the need for multiple setups, and enabling precise and simultaneous cutting from multiple angles. This capability results in improved part accuracy, shorter production times, and the ability to manufacture intricate components that may be challenging for less advanced machines.

What are the typical workspace dimensions and travel ranges for this type of machining center to meet the needs of projects of different scales?

The typical workspace dimensions and travel ranges of a 5-axis gantry machining center vary, but they are designed to accommodate a wide range of project scales. These machining centers can feature workspaces that range from compact to very large, with corresponding travel ranges that suit the size and complexity of the components being manufactured. This flexibility allows them to meet the needs of both small-scale and large-scale projects, offering precision and adaptability in various industrial applications.

Size reference:

Table size: 8000 mm×3000 mm

All axis move X:8600 mm

Y1: 5800 mm

Y2: 5800 mm

Z1: 1550 mm

Z2: 1550 mm

What are the performance characteristics of 5 axis gantry machining centers in high-precision and complex parts manufacturing, and how can they improve the machining quality of parts?

5 axis gantry machining centers excel in high-precision and complex parts manufacturing due to their ability to precisely control tool orientations from multiple angles, reducing the need for repositioning. This results in improved part accuracy and surface finish, while their rigidity and stability minimize vibration and deflection. These features, along with the elimination of error-prone setups, contribute to enhanced machining quality and the production of intricate components with exceptional precision and consistency.

How can a 5 axis gantry machining center improve production efficiency while reducing production costs in industrial applications?

Increased versatility and flexibility: A 5 axis gantry machining center allows for more complex and intricate machining operations, such as drilling, milling, and tapping, on multiple sides of a workpiece.

Simultaneous machining: With its ability to move the tool in five different directions, a 5 axis gantry machining center can perform multiple operations simultaneously.

Reduction in manual labor: With automated features such as tool changers and pallet changers, a 5 axis gantry machining center can operate continuously without the need for manual labor.

Enhanced accuracy and precision: The 5 axis design allows for more precise and accurate machining, resulting in fewer errors and waste.

Efficient use of materials: The ability to rotate and tilt the workpiece in multiple angles allows for better utilization of the material, minimizing waste and reducing production costs.

Fast setup and programming: 5 axis gantry machining centers often come equipped with advanced programming software, making it easier and faster to set up and program the machine for different machining operations.

Higher productivity with smaller footprint: A 5 axis gantry machining center takes up less floor space compared to traditional 3 axis machining centers, allowing for more machines to be installed in the same area.

You must be logged in to post a review.

Reviews

There are no reviews yet.