This blog post will provide a comprehensive guide to Vertical CNC Lathes. It will cover the basics of what a Vertical CNC Lathe is, the advantages and disadvantages of using one, and the different types of Vertical CNC Lathes available. Additionally, the post will discuss the various applications of Vertical CNC Lathes, as well as the safety considerations that should be taken when using one. Finally, the post will provide tips and tricks for getting the most out of a Vertical CNC Lathe

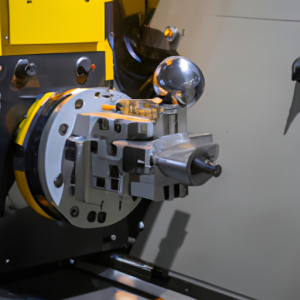

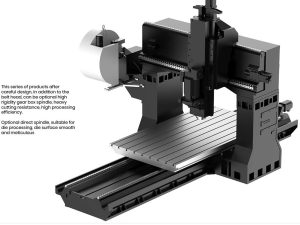

A Vertical CNC Lathe is a type of computer numerical control (CNC) machine tool that is used to shape metal and other materials into a variety of shapes and sizes. It is a type of lathe that is designed to work with a vertical spindle, which is mounted on a bed or table. The spindle is driven by a motor, and the cutting tool is mounted on the spindle. The cutting tool is then moved along the spindle to shape the material.

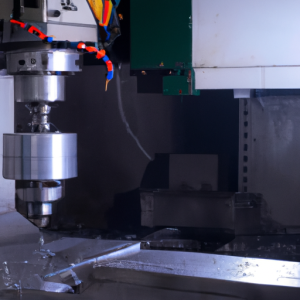

The advantages of using a Vertical CNC Lathe include increased accuracy, repeatability, and speed. The accuracy of the cuts is improved due to the fact that the cutting tool is mounted on the spindle and is not subject to any external forces. Additionally, the repeatability of the cuts is improved due to the fact that the cutting tool is always in the same position. Finally, the speed of the cuts is improved due to the fact that the cutting tool is driven by a motor.

The disadvantages of using a Vertical CNC Lathe include the fact that it is more expensive than other types of lathes, and it is more difficult to set up and operate. Additionally, the cutting tool is more prone to wear and tear due to the fact that it is constantly in contact with the material being cut.

There are several different types of Vertical CNC Lathes available, including horizontal, vertical, and combination lathes. Horizontal lathes are designed to cut material in a horizontal direction, while vertical lathes are designed to cut material in a vertical direction. Combination lathes are designed to cut material in both horizontal and vertical directions.

The applications of Vertical CNC Lathes are numerous. They are commonly used in the automotive, aerospace, and medical industries for machining parts and components. Additionally, they are used in the manufacturing of furniture, musical instruments, and other items.

When using a Vertical CNC Lathe, it is important to take safety precautions. It is important to wear protective clothing, such as safety glasses, gloves, and a face shield. Additionally, it is important to ensure that the cutting tool is properly secured and that the workpiece is securely clamped. Finally, it is important to ensure that the machine is properly maintained and that all safety guards are in place.

To get the most out of a Vertical CNC Lathe, it is important to use the correct cutting tools and to use the correct speeds and feeds. Additionally, it is important to use the correct coolant and lubricants, as well as to ensure that the machine is properly calibrated. Finally, it is important to ensure that the workpiece is securely clamped and that the cutting tool is properly secured.

In conclusion, a Vertical CNC Lathe is a powerful and versatile machine tool that can be used to shape metal and other materials into a variety of shapes and sizes. It offers increased accuracy, repeatability, and speed, but it is more expensive and more difficult to set up and operate than other types of lathes. Additionally, it is important to take safety precautions when using a Vertical CNC Lathe, and to use the correct cutting tools, speeds, and feeds to get the most out of the machine.