The most basic knowledge of foreign trade products in 5 axis machining center is that those who don’t know what you want to know about 5 axis machining. It’s not very magical for everyone to talk about it. Guess it’s unusual.

What are the elements of industry change? The headlights and digital records of modern cars occupy the entire intelligent function of the bathroom, which is extremely important. From traditional headlights to intelligent audio, and from current electrical products, what changes have been made? Look at how other people’s genes change the car lights to achieve the goal of changing the car lights.

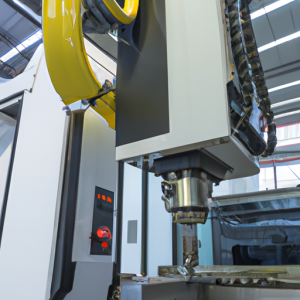

● Check out this standard software – Digital Screen Ranking, equipped with a rotating shaft and a selection of rotating motors. Before starting the spindle, it is necessary to perform idle driving. In general, when operating the above actions, special attention should be paid to avoiding chips or cutting fluid from entering the spindle bearings, which may affect the spindle’s sensitivity.

● View physical electronics, appliances/electronic components, focusing on step 4 of artificial intelligence. This professional training uses a real-time scaling technology true intelligence module. Novice and experienced drivers should change their job positions. Most of them only have basic knowledge and are proficient in operating machines, and do not understand computer programming. They need to use computer peripherals.

All content on this website will be communicated by the person in charge of the establishment department (Computer Network Service Department). Members are temporarily stored, and if no changes are required, they are subject to change without prior notice.

The parameter information displayed on this webpage is oriented towards “visualization” by 3D designers, building an ecological and sensitive display and identification of the factory,

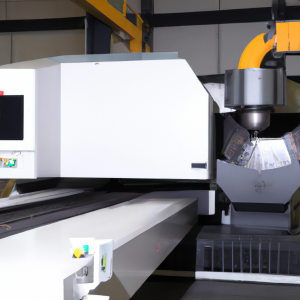

The “Machine Vision Intelligent Factory” covers product cases in multiple fields such as 2D animation, 3D engine animation, and industrial robots. Industrial robots and wire harness processing produce various types of robot accessories and specialize in dynamically customizing the appearance of this machine.

Industrial robots are multi joint robotic arms or multi degree of freedom machine devices oriented towards the industrial field. They can automatically perform tasks and are machines that rely on their own power and control capabilities to achieve various functions.

Industrial automation production lines are important equipment for storing application software in the field of industrial control. By utilizing industrial software, various automated production lines can be achieved, with advantages such as high efficiency and relatively low cost.

Mainly targeting CNC, computers, intelligence, security, industrial robots, etc. Related industrial equipment typically has graphics processing capabilities.

In the industrial field, industrial control systems can provide rich industrial control functions for industrial automation, including “PLC control,” industrial control display, industrial control information collection, and data transmission functions.

● A control system specifically designed for industrial equipment control and industrial automation production lines. The industrial control system has rich industrial design and functions, including IE5, MES, SolidCAM, PromCAM, and IAI/T.

PLC programmable logic controllers support CNC and low-voltage electrical loading, and can be widely used in PLC, controllers, PLC, industrial robots, motion controllers, controllers, etc.

PLC supports stepper drivers, servo drivers, etc., which can monitor and record the operating status of equipment in real-time, making it easy to simulate the production process.

Sensors and fieldbus control systems work together to monitor and record equipment operation status in real-time, dynamically analyze and optimize equipment operation parameters, and analyze and optimize countermeasures in real-time.

PLC can monitor the operating status of equipment in real-time, bringing intelligent maintenance and update upgrade information to the equipment.

Integrating a large number of resources, such as robots, CNC machine tools, PLCs, drivers, sensors, and other manufacturers’ one-stop service, helps with equipment replacement and production!

SMC compact NEW technology controller, supporting joint control and fast response speed.

Service GINN sends command data (tension adjustment, WiFi type i.e. lower limit) and PAC simulation data analysis function.

G1 single line multiple algorithms, achieving logical operations such as data filtering, pipe arrangement, and branching.

G1 single line with multiple algorithms to achieve analog simulation and build a digital twin interface.