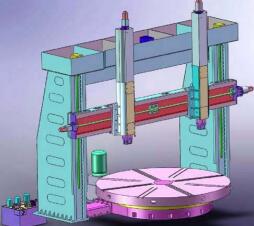

Vertical lathe CK5250/63

Double column vertical lathe

Description

Introduction

The CNC Double Column Vertical Lathe model CK5250/63 is a combination of modern advanced mechanics,

electrics and hydraulics basing on extensive experience, special focus and professional skills in the design

and manufacturing of large scale vertical lathes. It is designed and manufactured with latest technology

know-how, optimized design, quality material, fitting and best process for manufacturing and assembly.

It features,

★ High rigid thermo-symmetrical gantry structure for superb stability even at severe cutting conditions

★ Heavily ribbed base and table with hydrostatic axial bearing for big load capability

★ Modular design easily to be customized to suit customer’s diverse machining needs, ie. turning, milling,

drilling, threading and grinding.

It is designed and manufactured to meet modern machining requirements with high speed cutting tools and

carbide cutters on workpieces of cast iron, cast steel, alloy steel, fabricated steel and other materials.

3. Main features

★ Suitable for 380v/50HZ/3PH, or local power supply,

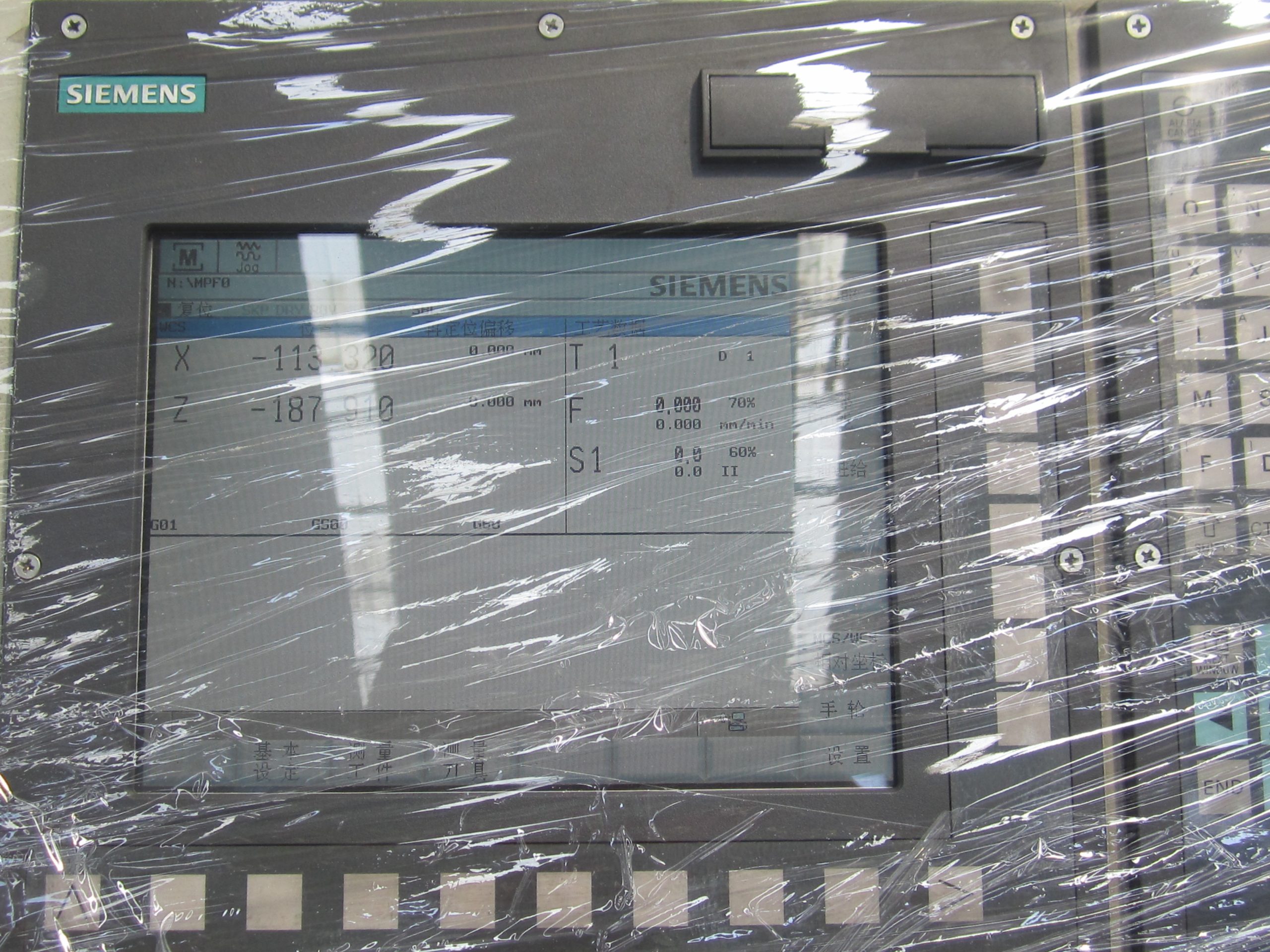

★ Reliable & powerful Siemens SINUMERIK 828D s.l. CNC control, or FANUC OI

★ High grade cast iron structure of main bodies for super stability, reliability & longer machine life,

★ Centralized operation button station and pendent operation panel,

★ Table with manual 4-jaw chuck with chucking jaws,

★ CNC controlled left tool head and buttons & switches controlled right tool head,

★ Square toolpost on vertical heads, especially suitable for deep hole machining,

★ Forged shafts used in the table speed change gear box,

★ 2 spindle speed gears, within each gear variable speeds are achievable for the table,

★ Hardened & ground gears in table speed change gearbox for smooth running,

★ High precision bearings used for supporting precision ballscrews (X / Z axes) on tool heads,

★ Automatic compulsory lubrication system for tool heads and cross rail guideways,

★ High power DC 110 kW main motor with DC digital drive unit (Eurotherm / PARKER brand),

★ Air conditioner for independent electric cabinet, especially suitable for tropic climate,

★ Work lamps for sufficient lighting,

★ Independent hydraulic power pack, easier for adjustment & maintenance,

★ Hydrostatic axial bearing table with constant flow power supply (0.2-0.4Mpa),

★ 12 pockets big axial hydrostatic bearing area ensuring big table load capacity,

★ Automatic clamping of cross rail onto the columns for heavy duty cutting,

★ C45 steel rams are induction hardened & ground for improved dynamic performance & longer life,

★ Anti-wear industrial Zinc-Aluminum alloy (ZnAl10-5) lining on sliding guideways and wear-resistant

Zinc-Aluminum alloy (ZnAl10-5) lining engraved on table guideways for longer machine life,

★ PLC unit (DELTA / OMRON brand) integrated in electrical system for reliable functioning,

★ Servo feeding motors & ballscrews are used for feeding of both tool heads,

★ Telescopic steel covers on cross rail guideways to avoid intrusion of chips, dust, oil,

★ Telescopically moveable operation platforms provided at both sides of the cross rail for easier

observation and operation (optional).

★ Affluent safety & protection setting-ups & interlocks are integrated with the machine, etc

| Max. turning diameter (mm) | 5000/6300 |

| Table diameter(mm) | 4500/5800 |

| Max. working height of work-piece(mm) | 3500/4000 |

| Max. cutting resistance of right tool post(CNC)(KN) | 100 |

| Max. cutting resistance of left tool post (PLC)(KN) | 80 |

| Max. torque of table(KN·m) | 450 |

| Speed range of table(r/min) | 0.155~162r/min, 2 gears, stepless |

| Rapid traveling speed of tool post(mm/min) | 2000 |

| Table guide | Static Hydrostatic |

| Moving degrees limit of tool post(°) | -15~+30 |

| Controller | FANUC OL MD/SIEMENS 828D |

| Position accuracy | Test and evaluate accuracy

according to GB/T17421.2-2000 |

| Positional accuracy(mm) | X Z 0.03/1000 |

| Repeatable positional accuracy(mm) | X Z 0.015/1000 |

| Reverse positional accuracy(mm) | X Z 0.010/1000 |

| Max work pieces load (T) | 150 |

| Temperature range(°) | 0~40° |

| Ambient humidity | ≤85% |

| Power supply and voltage | 380V±10% or specified |

| Travel of tool post Horizontal(mm) | -50-4500mm |

| Travel of tool post (Vertical)(mm) | 2250 |

| Number of feeds | Stepless |

| Feed range of table(mm/min) | 0.1~500 |

| Travel of crossbeam(mm) | 3000 |

| Moving speed of the crossbeam(mm/min) | 300 |

| Machine weight | 240 |

| Power of main motor(KW) | 55 |

Castings

Main bodies of the machine are made of high rigid resin sand castings with thermal / vibratory stress relief

(VSR) aging treatment. Steel parts are thermal refined.

○ resin sand casting,

○ high grade, high intensity and low stress

○ stress relieved castings to absorb the stresses and dampen the vibration during cutting

Machine structure

★ Thermo-symmetrical gantry frame structure

The machine adopts a stable thermo-symmetrical gantry frame structure and consists mainly of base,

table, R.H. and L.H. columns, cross rail, top beam, tool heads, hydraulic system and electric system.

Columns and cross rail are of box-shaped castings with numerous reinforced ribs. Two columns are

connected through the top beam on the top and bolted to the base at the bottom so to form a superb

rigid and stable structure that is qualified for stable and heavy cutting even at severe cutting conditions.

Base with spindle and bearing

The base is made of heavily reinforced ribbed grey cast iron and stress-relieved after rough machining.

Heavy load short-shaft type spindle is placed in the center. High precision (P5 class) preloaded double row

cylindrical roller thrust bearing is equipped to support the spindle radically. Inner conic ring of the

bearings can eliminate the radial clearance effectively for high precision positioning of spindle and

stable rotating at high speed. Big size hydrostatic bearings are adopted axially on the base for improved

loading capacity. Hydrostatic guideways are Zinc-Aluminum alloy lined and matched. Constant flow

hydraulic oil flows in through regulating distribution mechanism.

Constant flow synchronous pumps and a multi-head synchronized oil distributor are adopted to provide

constant oil to each individual pocket of the 12 oil pockets on the base upper guideways via regulating

valves. An oil pressure relay is equipped. Once oil pressure is less than the rated value, alarm will be given

and rotation of the working table will not be allowed.

Hydrostatic bearing features:

a). low friction for smooth rotation and long life of table,

b). heavy load capacity on table,

c). oil film between machine base and table absorbs cutting vibration & loads,

d). safety system regulating the hydrostatic pressure for optimum safety.

Table

The table is made of high grade cast iron with numerous reinforced ribs for superb rigidity. Four heavy duty

jaws are fitted on the table. A ring gear is fitted under the table. Surfaces under the table are engraved with

wear-resistant Zinc-Aluminum alloy lining.

Cross rail

Cross rail moves up and down along guideways of columns. Elevation of the cross rail is through a

mechanism that consists of an asynchronous motor, driving shafts, worm gear boxes, trapezoidal

leadscrews, etc. Cross rail is lifted simultaneously through the trapezoidal screws.

○ Cross rail will be clamped automatically on to the column after reaching the required position and

will be relieved for movement. Clamping pads are equipped to assure stable & reliable clamping of the

cross rail for preparation of heavy cutting.

○ Telescopic covers are equipped on the cross rail to keep it from intrusion of chips & dusts.

○ Automatic compulsory lubrications units are equipped for lubrication of the guideways.

○ Contacting surfaces at the back of the cross rail are lined with wear-resistant industrial alloy

material for smoother travels and longer machine life.

Manufacturing standards

Accuracy: as per China standards JB4116-85 (basically equivalent to ISO 3655-1986)

Working conditions

1. Power supply: 3800V±10%, 50Hz±1Hz, 3Ph

2. Ambient temperature: 5℃ – 45℃

3. Relative humidity: ≤85% (at 20℃)

4. Machine noise: ≤85dB @ idle running

5. Altitude: ≤1500mm

6. Environment: clear from harmful gas, liquids, dusts and vibration, magnetic and radiation sources, etc

You must be logged in to post a review.

Reviews

There are no reviews yet.