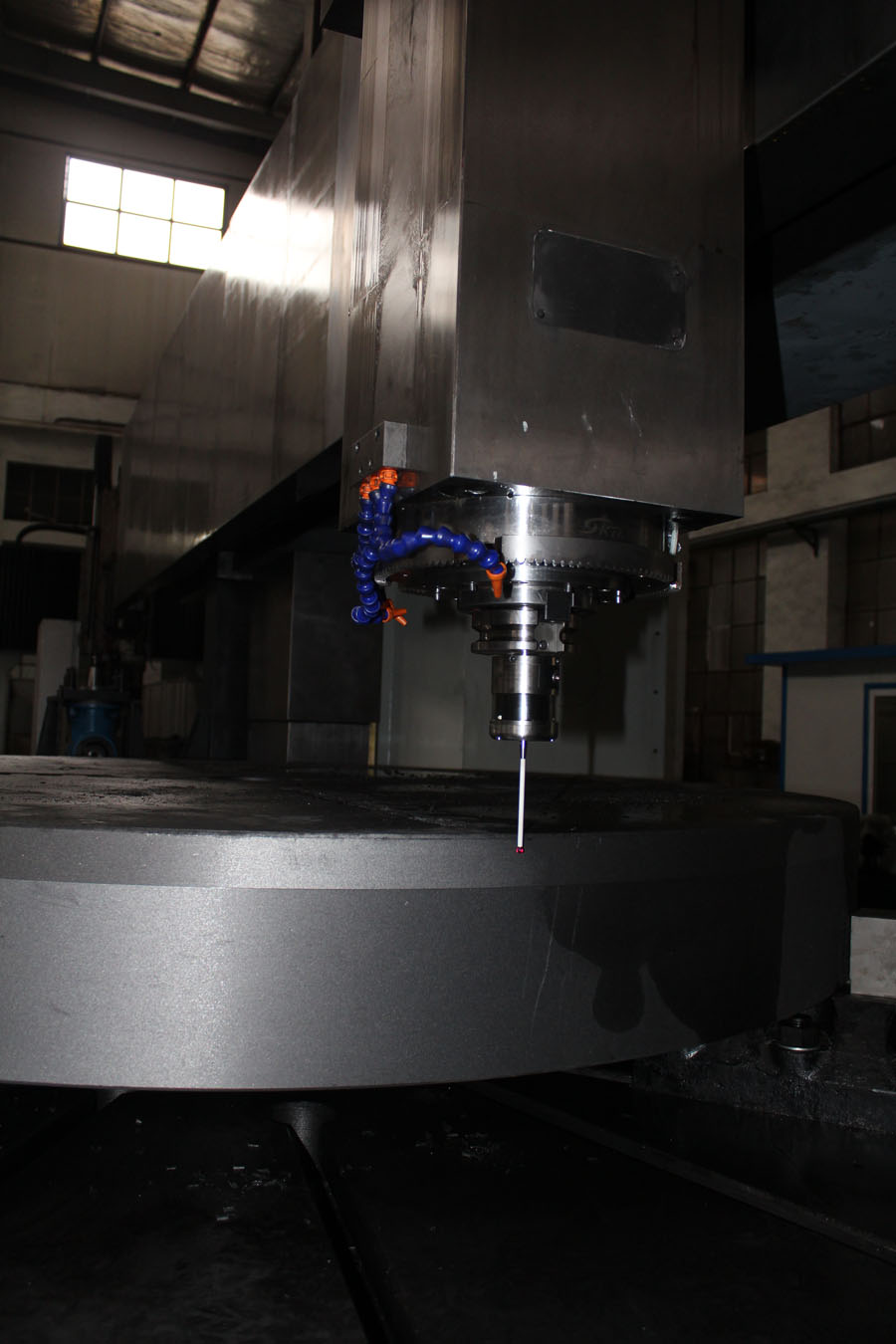

Milling & Turning Vertical lathe CXK400

Vertical lathe with C- Axis

Description

- Worktable base: The material of the worktable base is HT250, and the worktable base is subjected to thermal aging and stress relief annealing treatment. BaseThe design adopts symmetrical cloth reinforcement technology, high load capacity, high rigidity and high stability design, and low thermal deformation.

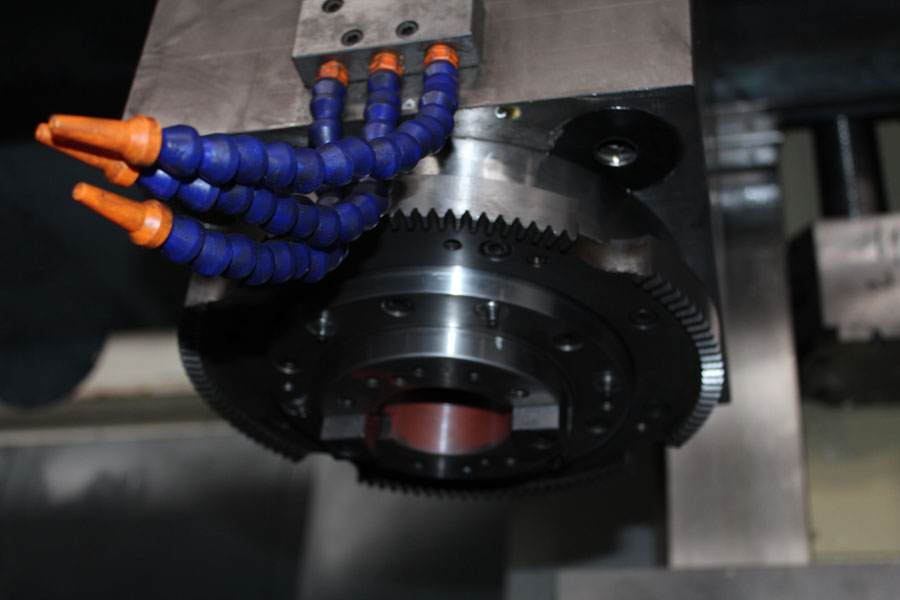

- Workbench: The workbench is made of HT300 material. The solid workbench is designed to be heat-aged, stress-relieved and annealed. MaximumThe workpiece weighs 32tons. The maximum rotating diameter of the table is 2830 mm, and the maximum workpiece processing diameter is 3200 mm. Workbench center Unique high-precision and high-resolution circular grating for detecting the C-axis position of the worktable, large gears and two-axis teeth of the worktable The wheel is made of 40Cr material and has precision grade 6 teeth. The center of the worktable has a centering hole with an accuracy of H7, and the worktable is equipped with 4 four-claw Manual jaws. The main shaft bearing of the worktable adopts cross roller bearing, high precision and high load capacity, the speed of the worktable is 1-400r / min, Among them, the low-speed I gear is 1-150r / min, and the high-speed II gear is 150-400r / min.

- Variable speed of working table: The variable speed of working table adopts the stepless speed regulation of high torque two-speed servo spindle motor of Emcker, with constant linear speed turningFunction and threading function. The main shaft gear and the second shaft gear adopt 40Cr grinding gear (level 6 precision). On the main shaft gearAnother high-precision C-axis gearbox with deceleration transmission is driven by a synchronous servo motor and has an electronic gear anti-backlash structure.

- Bed: The bed is made of HT300 material, after heat ageing stress relief annealing treatment, multi-layer thick rib wall, symmetrical cross compound high rigidSexual design, no sand cleaning, increase bed damping. The bed is located on the base of the workbench, and is connected to the base of the workbench by boltsTogether. The bed adopts symmetrical design and computer finite element analysis. The design is mature and stable, and the thermal deformation is small. Used between bed and base Special bolts are used to adjust the level of the column. After the adjustment is completed, the latest glue injection positioning technology is used to firmly connect the bed column to the base. put them together.

- Cross beam lifting: The cross beam lifting adopts a dual-axis extension motor to drive the worm gear worm trapezoidal screw lifting mechanism, and adopts hierarchical positioning

Function, hierarchical positioning function can control the horizontal beam each time it is lifted within the same horizontal range, effectively reducing the lifting error. Dang heng

After the beam is lifted into place, there are four hydraulic clamping mechanisms to firmly lock the crossbeam on the upright. The upper and lower beams are equipped with electrical limits,

Safe and reliable.

- Crossbeam (with ATC servo tool magazine): The crossbeam is made of HT300 material, which is annealed by thermal aging and stress relief. Cross beam guide

Roller-sliding composite guide rails are used, mainly roller-type linear guide rails, supplemented by hard-rail composite guide rails. The surface of the sliding rail (hard rail) is quenched by super audio

Treatment (above HRC50), the sliding seat surface in sliding contact with it is treated with wear-resistant plastic (soft tape) to increase the accuracy of the guide rail

Sex and rigidity. The beam is equipped with a white steel protective cover, which is beautiful and elegant. At the right end of the beam is equipped with servo-driven ATC double-layer tool magazine,

The lower level milling tool magazine (BT50) has 24 stations and the maximum milling tool weight is 25Kg; the upper level is a 6 station turning tool magazine with the maximum turning tool weight

60KG, in the upper 6-station turning tool magazine, a place for mounting a large angle milling head is reserved, and a right angle milling head is optional. Tool magazine

The automatic pneumatic sliding door mechanism is adopted, and the tool magazine door automatically opens when the ram enters the tool magazine to pick up the tool, and the tool magazine door closes automatically after the tool is taken.

The tool magazine area is separated from the machine tool work area by pneumatic doors. The tool magazine is equipped with a full range of detection sensors for detecting tool position and tool

Alarms for release, tool magazine tilt, tool impact, etc.

- Ram: The ram is made of 45 steel forging material, after heat and tempering treatment, the structure is square, and the cross section of the ram is 255X255mm. slip

The front end of the pillow is equipped with a milling spindle made in Taiwan, and the milling shank adopts the BT50 standard. The milling spindle has a directional accurate stop function, which can rigidly tap. slip

The pillow is equipped with a hydraulic balancing cylinder. The front of the ram is equipped with a hydraulic broach cylinder made in Germany, with a total broaching force of 80Kn, and the turning tool holder is the end face

Spur gear positioning, high rigidity and high precision, there will be no loosening of the tool holder when eating a large knife.

- Hydraulic system: The hydraulic system uses two independent hydraulic stations, which is convenient for adjustment, repair and maintenance. One of the hydraulic stations is independent

Stand for cooling system, the other is the main pressure system. The hydraulic system provides pressure to the hydraulic locking of the beam, the grading positioning cylinder, the milling master

Lubrication or cooling of shaft knife loose knife, table bearing lubrication, ring gear, milling spindle cooling, gearbox, etc.

- Machine tool lubrication system: each sliding part of the machine tool is automatically and quantitatively supplied with oil by an automatic lubrication pump, and the oil supply is calculated by the system on X and Z axes

Accumulated travel path is automatically controlled, and has a manual auxiliary oil injection function. There is a pressure transmitter at the far end of the oil supply circuit of the automatic lubrication system Sensor.

- Electrical system: Independent electrical cabinets are equipped with refrigeration and air conditioning. The CNC system is Siemens D system, 10.4-inch LCD color

The panel has one front and one rear USB2.0 interface, one industrial Ethernet port; the system can be equipped with FMS communication interface,

With remote control, diagnosis, transmission, program management, machine tool monitoring and other functions. The servo drives are all original Siemens products,

Equipped with a hand-held control box, the control box is equipped with electronic handwheel and common operation buttons. The electrical cabinet is IP54 protection grade, TN-S

System power supply (three items and five wires are recommended, and the grounding resistance is less than 6 ohms). Machine tool X, Z, C, ATC axis manual feed by the manipulator Holding unit.

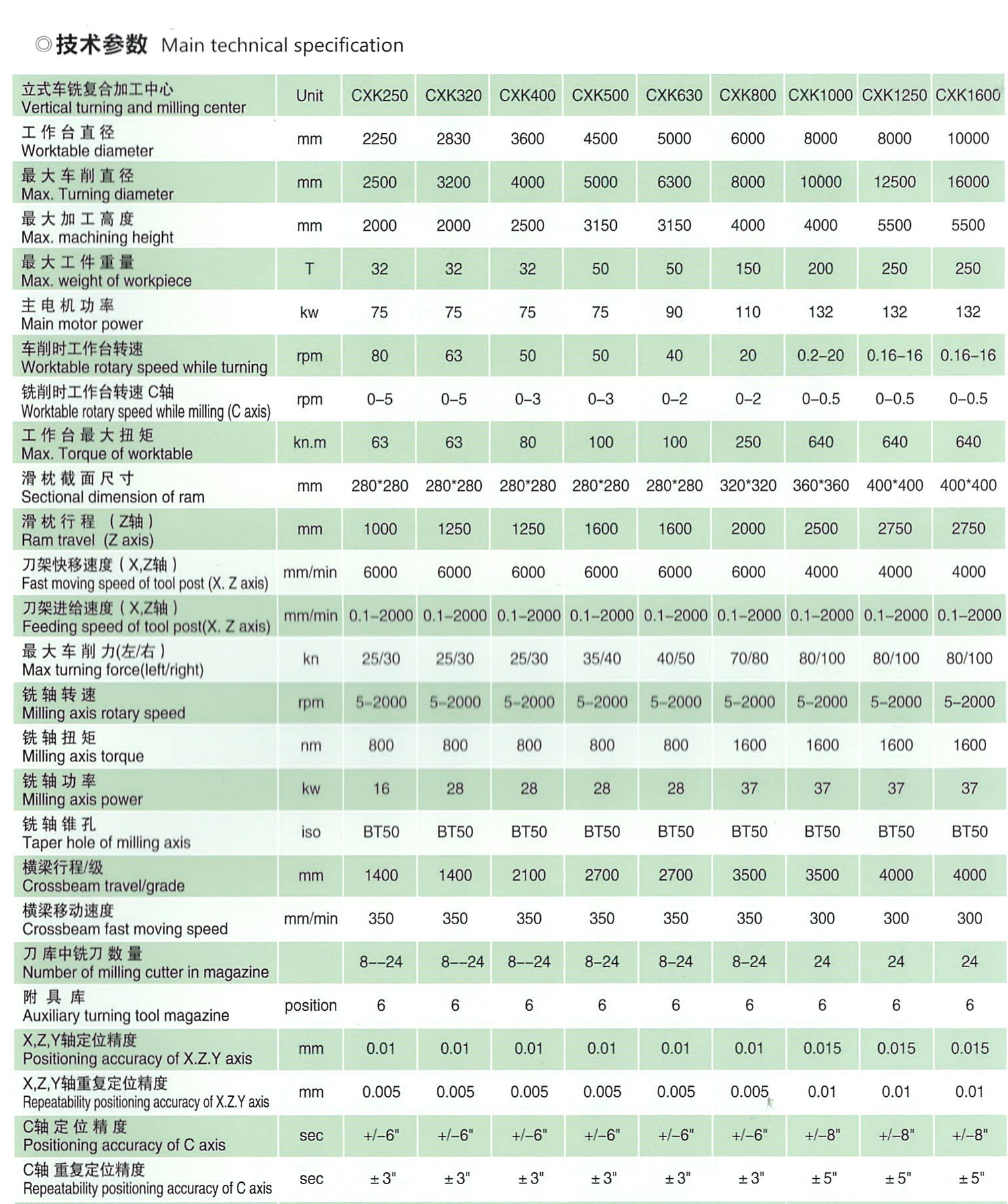

Specification:

You must be logged in to post a review.

Reviews

There are no reviews yet.