cnc machining minneapolis

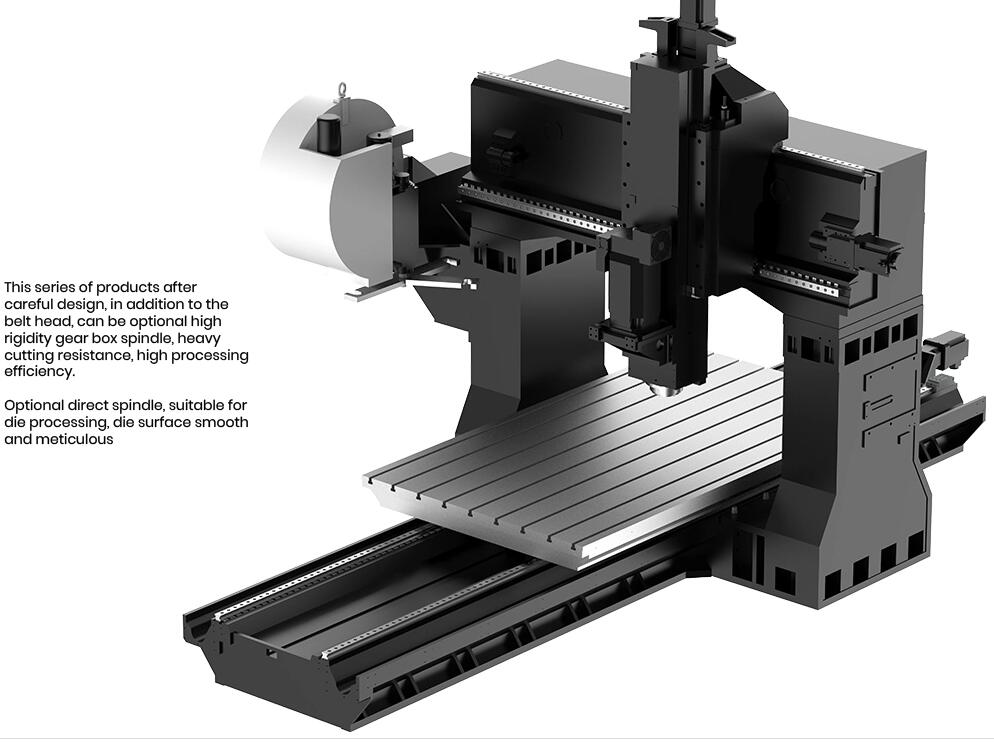

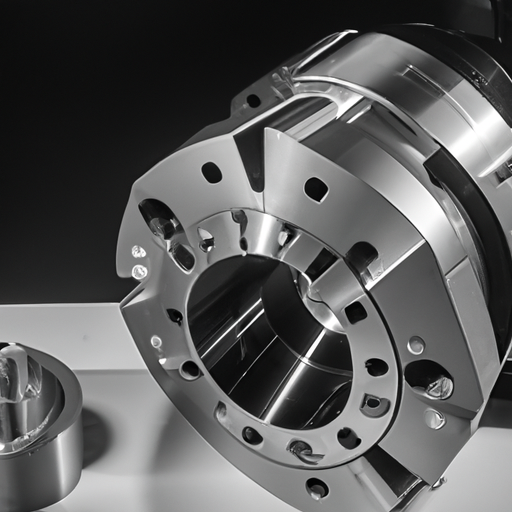

The spindle adopts Taiwan spindle

The feed motor adopts FANUC original motor

The spindle motor adopts FANUC original motor

The X-axis screw adopts the Spanish ipiranga European standard IT5 level

Y/Z axis screw adopts Japanese THK precision grinding C3 level

The guide rail adopts the silver roller P grade precision

The bearing adopts Japanese NSK precision P4 bearing

Description

Weish CNC Co., Ltd is located in Ningbo City, Zhejiang Province. We have always been devoted to the research and manufacture of CNC machines. We have R & D Production Department, Quality Control Department, and Sales & Service Department. Our products are widely used in shipbuilding,steel,aerospace,weapons,machinery,shipbuilding,energy,printing and so on.

We can offer you high quality products with the competitive price. Our products got the CE certificate. Our main products are Router machine,planner type boring,Cnc Horizontal Machining Center,Vertical lathe,CNC gantry milling machine,horizontal boring machine(table type),5 axis machining center,double column lathe,single coulumn lathe,CNC machine center and so on. With advanced technology, high quality, reasonable price and perfect post-sales service, our products have attained favorable comments among other our clients and our business has developed rapidly.

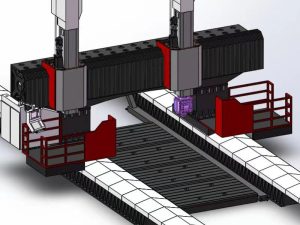

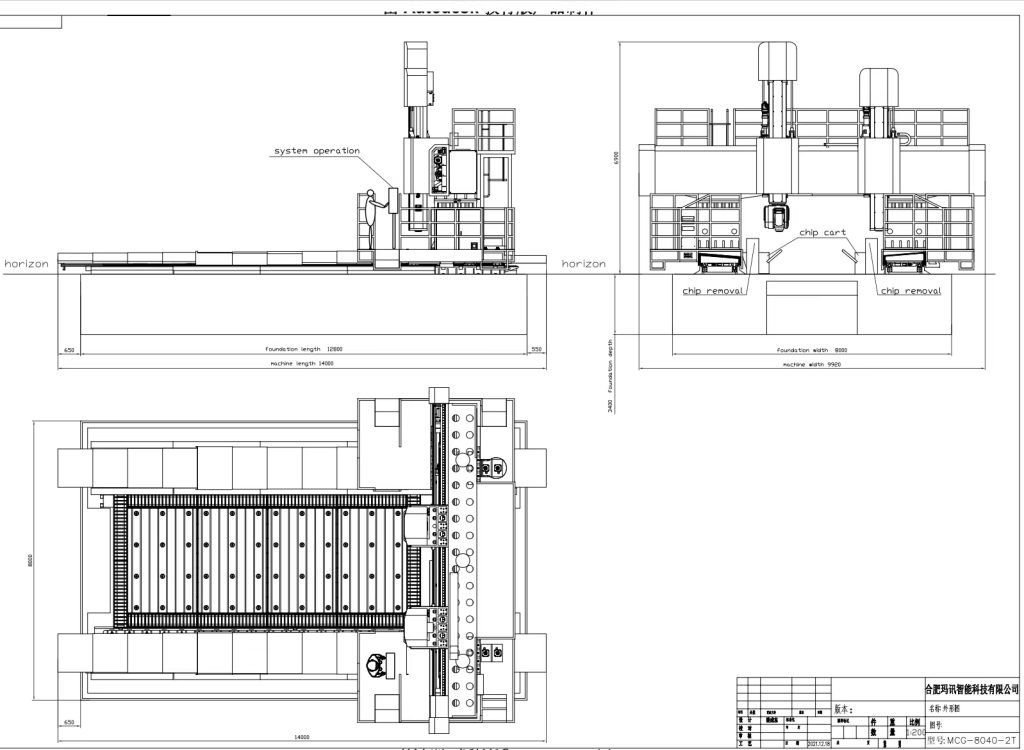

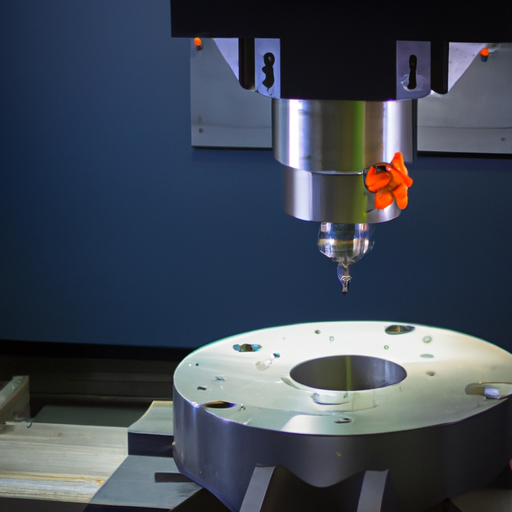

cnc machining minneapolis produced by WEISH CNC MASTER uses a gantry to move on the base, and the workbench is fixed between 2 columns. It occupies a small area and the user’s investment cost is low. The processing height can be determined by the height of the mud when the user installs.

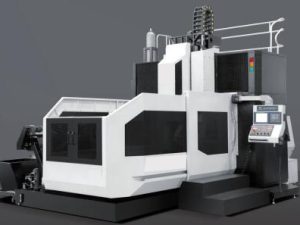

It has the characteristics of heavy cutting,good stability,good dynamic characteristics,high rigidity,large torque,strong vibration absorption. The machine tool’s technical indicators and configuration are domestically leading, its product structure and technology are mature, and its product quality is stable.

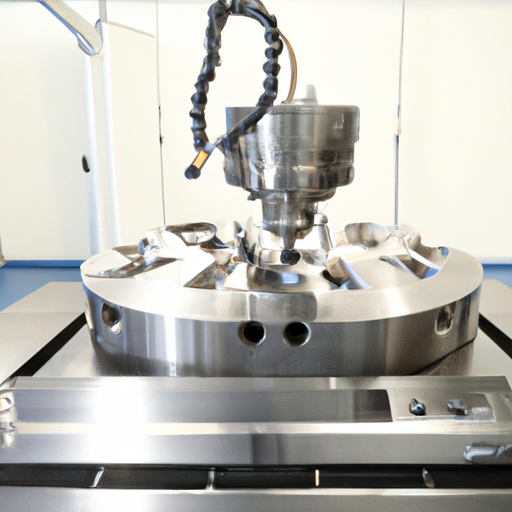

Beam: Strengthen structure. HT300

Main spindle motor: Original SIEMENS AC motor

Linear Guideway: #65

5 Axis head: MEPRO / Optional

Y1 and Y2 axis ball screw: 80mm

Bearing: FAG Germany / NSK Japan

Couping: NBK Japan

Reducing: ALPHA Germany

CNC SYSTEM:SIEMENS 840D

X.Y.Z. is 3 axis linkage controlled by system. Table moving and column fixed Cross beam fixed

1:promise to replace the broken part of machine during the warranty period

2:The seller(WEISH CNC MASTER) will dispatch technicians to the customer’s designated location for installation and debugging based on customer needs. Includes Training, commissioning and programming

3:we can provide the remote training if customer don’t need the on-site installation

| Product name | cnc machining minneapolis |

| Brand Name | Weish CNC Master |

| Product Type | CNC machine |

| Place of Origin | China |

| Product Size(CM) | 488*184*224(Please consult us for specific details) |

| Motor power(KW) | 22 |

| Core Components | Motor,Gearbox,Engine |

| Use | printing,automobile,energy…etc |

| Colors | Standard Grey+Customizable |

| Export region | Africa,Europe,America… |

| Export countries | Russia,India,Morocco,Netherlands,Paraguay…etc |

| Main spindle motor | Original SIEMENS AC motor |

| Certification | CE |

| Voltage | 220V/380V |

| Guideway | HIWIN Taiwan |

| MOQ | 1 Set |

| Port | Ningbo |

| Cnc System | SIEMENS 840D |

| Bearing | FAG Germany/NSK Japan |

| Payment method | 30% TT prepaid.60% TT proceeding. 10% before shipment |

| Packaging Details | 3(or5)x40” OT for loading |

| Lead time (days) | 25-30(To be negotiated) |

| Supply Ability | 30 Set/Sets per Year (See specific model products) |

Please note: This table is for reference only, please consult us for specific information.

cnc machining minneapolis–A Guide to Frequently Asked Questions

2.Does the cnc machining minneapolis have a cooling system to control temperature?

3.What are the advantages of cnc machining minneapolis technology?

4.What is the production capacity of the factory for cnc machining minneapolis?

5.Does the cnc machining minneapolis device have an automated loading and unloading system?

6.About cnc machining minneapolis,What is the delivery time?

7.How fast does the cnc machining minneapolis work?

8.Does the cnc machining minneapolis support High Speed Machining?

9.Development status of cnc machining minneapolis industry

10.Can the processing capacity of the cnc machining minneapolis be expanded or customized?

11.What is cnc machining minneapolis and how does it work?

12.What are the different sizes and models of cnc machining minneapolis available?

13.What is the general power of the cnc machining minneapolis spindle?

14.What are the security features of cnc machining minneapolis?

15.About cnc machining minneapolis,Can your offer customized service?

16.What are the sustainability and environmental characteristics of the cnc machining minneapolis?

1.About cnc machining minneapolis,Do you have any certificates?

Yes, our machine is CE-compliant, and our factory is ISO 9001 accredited.

2.Does the cnc machining minneapolis have a cooling system to control temperature?

Yes. Lubricate system. Cutting oil temp control system

3.What are the advantages of cnc machining minneapolis technology?

cnc machining minneapolis can effectively reduce the processing time and auxiliary time of parts. The CNC machine tool has a wide range of spindle speed and feed rate, allowing the machine tool to perform powerful cutting with large cutting volumes, rapid movement and positioning of CNC machine tool moving parts, and high-speed cutting, reducing the inter-process turnover time of semi-finished products and improving production efficiency.

4.What is the production capacity of the factory for cnc machining minneapolis?

30 sets per year

5.Does the cnc machining minneapolis device have an automated loading and unloading system?

Yes. Robot.Fully automatic machining system.

6.About cnc machining minneapolis,What is the delivery time?

The full series of standard models are in stock. For a customized one, it depends.

7.How fast does the cnc machining minneapolis work?

X/Y axis rapid feed speed:8000 rpm. Z axis rapid feed speed:8000 rpm. W axis rapid feed speed:2000 rpm.

8.Does the cnc machining minneapolis support High Speed Machining?

Yes.Cutting speed:10-10000mm/min

9.Development status of cnc machining minneapolis industry

The application of cnc machining minneapolis technology has penetrated into various fields and has become an important part of manufacturing production. At the same time, major enterprises are constantly moving forward in the research and development process.

Practice has shown that the application of cnc machining minneapolis technology can greatly improve the accuracy and efficiency of part production, reduce cutting costs, and thus effectively improve the operational efficiency of enterprises. and competitiveness.

10.Can the processing capacity of the cnc machining minneapolis be expanded or customized?

Yes. We can make the gantry milling machine in Professional customization

11.What is cnc machining minneapolis and how does it work?

It is an automated machine tool equipped with a program control system. The control system can logically process programs with control codes or other symbolic instructions, decode them, express them with coded numbers, and input them into the numerical control device through the information carrier. After calculation and processing, the CNC device sends out various control signals to control the movement of the machine tool and automatically process the parts according to the shape and size required by drawing.

Working Principle When using a CNC machine tool, the geometric information and process information of the drawings of the parts to be processed must first be written into a processing program using the prescribed code and format; then the processing program is input to the CNC device, and the CNC system information is processed according to the requirements of the program. , distribution, so that each coordinate moves a certain minimum displacement amount to realize the relative movement of the tool and the workpiece to complete the processing of the part.

12.What are the different sizes and models of cnc machining minneapolis available?

WEISH CNC MASTER make the gantry milling machine in Professional customization

13.What is the general power of the cnc machining minneapolis spindle?

Usually 37-55KW

14.What are the security features of cnc machining minneapolis?

Automatic power-off,Full loop protection, Crush detective system

15.About cnc machining minneapolis,Can your offer customized service?

Yes, we can. Please provide the specification for the machine you need, and tell us your requirements.

16.What are the sustainability and environmental characteristics of the cnc machining minneapolis?

The spiral chip conveyors on both sides of the processing area quickly transport the iron chips generated by high-speed machining to the lifting chip conveyor, reducing thermal deformation of the machine tool and ensuring the accuracy and stability of the chip conveyor on both sides of the machine bed; the chip conveyor is equipped with an automatic oil-water separation device, which has an environmentally friendly effect good.

Tags:avid cnc machine,cnc roll forming machine,cnc machining epoxy tooling board,portable cnc router machine,cnc machine movers,thunder cnc machine