In the sophisticated world of CNC machining, G-code is the language that drives precision and efficiency, especially in 5-axis milling head operations. Weish CNC, a premier CNC machine manufacturer, emphasizes the importance of mastering G-code to unlock the full potential of 5-axis milling. This article delves into the intricacies of G-code programming and how Weish CNC leverages its expertise to deliver superior CNC machining solutions.

- Understanding G-Code

What is G-Code?

G-code is a standardized programming language used to control CNC machines. It dictates the movement of the machine’s tools, including direction, speed, and path, to execute precise machining tasks.

Key Components of G-Code:

G-Codes: Commands that control the movement and operation of the machine (e.g., G00 for rapid positioning, G01 for linear interpolation).

M-Codes: Miscellaneous functions such as turning the spindle on/off or coolant control (e.g., M03 for spindle on, M05 for spindle off).

Coordinates: Specify the position of the tool in the machine’s coordinate system.

- Advantages of G-Code in 5-Axis Milling

Precision and Control:

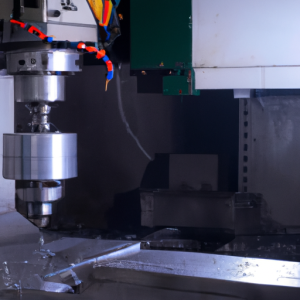

G-code allows for exact control over the tool’s movements, enabling the machining of complex geometries with high precision.

The ability to define precise tool paths ensures consistent quality across all parts.

Flexibility and Versatility:

G-code can be customized to meet the specific needs of different projects, making it highly versatile.

It supports various operations such as drilling, tapping, and contouring, which are essential for 5-axis milling.

Efficiency:

Efficient G-code programming can significantly reduce machining time by optimizing tool paths and movements.

Minimizing tool changes and machine downtime enhances overall productivity.

- Key Considerations for G-Code Programming in 5-Axis Milling

Tool Path Optimization:

Smooth Transitions: Ensuring smooth transitions between different tool paths to avoid abrupt movements that can affect surface finish.

Collision Avoidance: Programming tool paths that prevent collisions between the tool and the workpiece or fixtures.

Machine Capabilities:

Understanding the specific capabilities and limitations of the 5-axis milling machine being used.

Leveraging advanced features such as simultaneous multi-axis control to achieve complex shapes.

Material Properties:

Adjusting feed rates and spindle speeds based on the material being machined (e.g., different settings for aluminum versus stainless steel).

- Advanced G-Code Techniques

Subroutines and Macros:

Using subroutines and macros to simplify complex programs and reduce code redundancy.

Enhancing programming efficiency by reusing common sequences.

Parametric Programming:

Implementing parametric programming to create flexible and adaptable programs that can be easily modified for different parts and operations.

Utilizing variables and expressions to control tool paths and machining parameters dynamically.

Simulation and Verification:

Employing simulation software to verify G-code before actual machining, identifying potential issues and optimizing tool paths.

Reducing the risk of errors and ensuring the program runs smoothly on the machine.

- Why Choose Weish CNC for 5-Axis Milling Solutions

Expertise in G-Code Programming:

Weish CNC’s team of experienced programmers excels in creating efficient and precise G-code programs tailored to the specific needs of each project.

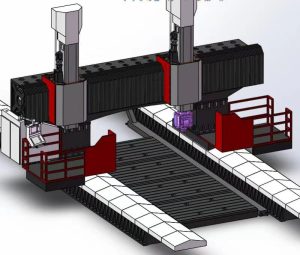

State-of-the-Art Technology:

Our factory in China is equipped with the latest CNC machines and software, enabling us to deliver high-performance 5-axis milling solutions.

Customized Solutions:

As an OEM/ODM partner, Weish CNC provides customized machining solutions that cater to the unique requirements of our clients, ensuring optimal results.

Reliable Supply Chain:

Weish CNC works with trusted suppliers and distributors to ensure timely delivery and consistent quality of all components and materials.

Cost Performance:

By optimizing our manufacturing processes and leveraging our expertise, Weish CNC offers competitive pricing without compromising on quality.

Conclusion

Mastering G-code is essential for achieving the full potential of 5-axis milling head operations. Weish CNC, a leading CNC machine manufacturer, combines advanced programming techniques, state-of-the-art technology, and a deep understanding of machining principles to deliver superior CNC solutions. Whether for complex aerospace components or intricate medical devices, Weish CNC’s expertise ensures precision, efficiency, and high-quality results.