Exploring the Future of CNC Boring Mill Technology

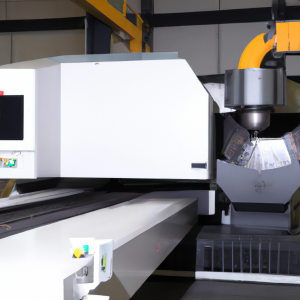

The world of CNC machining is continuously evolving, with new technologies and innovations shaping the future of manufacturing. CNC Boring Mills,…

The world of CNC machining is continuously evolving, with new technologies and innovations shaping the future of manufacturing. CNC Boring Mills,…

In the world of CNC machining, precision is paramount. To achieve the highest levels of accuracy and efficiency, the use of…

Introduction In the world of precision machining, selecting the right equipment is crucial for achieving optimal results. Two popular machines often…

FM, a leading CNC machining parts manufacturer, is committed to providing top-tier precision parts through advanced manufacturing technologies. One of the…

When it comes to precision and efficiency in manufacturing, the choice of machinery plays a crucial role. FM, a premier CNC…

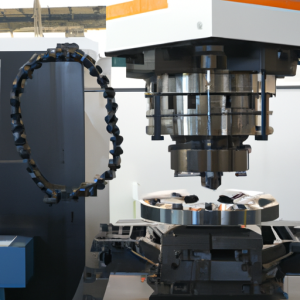

Introduction CNC boring mills are essential in precision machining, especially for applications requiring accurate hole dimensions and alignment in large and…

Introduction Investing in a reliable CNC machine center is crucial for any manufacturing operation seeking precision, efficiency, and versatility. As a…

Introduction In precision machining, taps and dies play a crucial role in creating threads on parts and components. When combined with…

Introduction In the realm of precision machining, choosing the right equipment is crucial for efficiency, accuracy, and overall production quality. As…

In the world of precision machining, both 5 axis milling heads and CNC boring mills hold significant importance. As a leading…