Introduction

In the realm of precision machining, choosing the right equipment is crucial for efficiency, accuracy, and overall production quality. As a leading CNC machine manufacturer, Weish CNC offers a variety of advanced machining solutions, including CNC machine centers and CNC boring mills. This article explores the benefits of CNC machine centers over CNC boring mills, highlighting why they might be the superior choice for many applications.

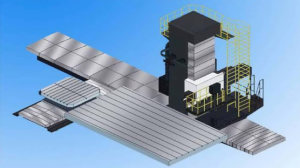

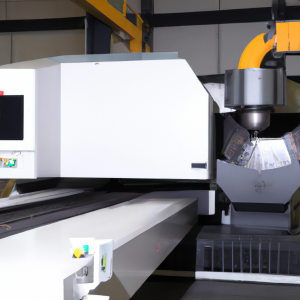

Understanding CNC Machine Centers

What is a CNC Machine Center?

A CNC machine center is a versatile piece of equipment designed for a wide range of machining operations, including milling, drilling, tapping, and boring. It integrates multiple functions into one machine, making it highly efficient and capable of producing complex parts with high precision.

Key Features

- Multi-Functionality: Combines various machining processes in one machine.

- High Precision: Achieves tight tolerances and superior surface finishes.

- Automation: Reduces manual intervention, enhancing efficiency and consistency.

- Flexibility: Suitable for a wide range of materials and complex geometries.

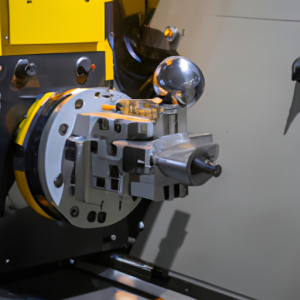

Understanding CNC Boring Mills

What is a CNC Boring Mill?

CNC boring mills are specialized machines designed primarily for enlarging existing holes in a workpiece with high precision. They are essential for applications requiring accurate hole dimensions and alignment, particularly in large and heavy workpieces.

Key Features

- Power and Stability: Capable of handling large and heavy workpieces.

- Precision Boring: Ensures precise hole dimensions and alignment.

- Depth Control: Excellent for deep hole boring with consistent results.

Benefits of CNC Machine Centers Over CNC Boring Mills

Versatility and Multi-Functionality

CNC Machine Centers: One of the most significant advantages is their ability to perform multiple machining operations such as milling, drilling, tapping, and boring. This multi-functionality reduces the need for multiple machines and setups, leading to higher efficiency and lower overall production costs.

CNC Boring Mills: While excellent for precise boring operations, they are limited to this function. For projects requiring a variety of machining processes, additional equipment is necessary, increasing complexity and costs.

Precision and Accuracy

CNC Machine Centers: Capable of achieving high precision across various operations, making them ideal for parts with complex geometries and tight tolerances. The integrated nature of these machines ensures consistent quality across multiple processes.

CNC Boring Mills: Provide excellent precision in boring applications but lack the versatility to handle other machining tasks with the same level of accuracy.

Efficiency and Setup Time

CNC Machine Centers: By combining multiple functions into one machine, setup times are significantly reduced. This efficiency translates into faster production cycles and improved cost performance.

CNC Boring Mills: Often require separate setups for different operations, leading to longer production times and increased labor costs.

Flexibility and Adaptability

CNC Machine Centers: Highly adaptable to different materials and part designs, making them suitable for a wide range of industries, from aerospace and automotive to medical devices and consumer electronics. Their ability to quickly switch between tasks enhances their utility in dynamic production environments.

CNC Boring Mills: Best suited for specific applications involving large, heavy workpieces and precise hole boring. Their specialized nature limits their adaptability to other machining tasks.

Automation and Integration

CNC Machine Centers: Offer advanced automation capabilities, including tool changers, automated workpiece handling, and integrated quality control systems. This automation reduces human error, increases production speed, and ensures consistent quality.

CNC Boring Mills: While some automation is possible, their focus on boring operations limits the extent of automation compared to machine centers.

Applications and Suitability

When to Choose CNC Machine Centers

- Complex Parts: Ideal for parts requiring multiple machining processes and intricate designs.

- High Precision: Suitable for applications with tight tolerances and superior surface finish requirements.

- Versatility: Perfect for industries needing flexible and adaptable machining solutions.

When to Choose CNC Boring Mills

- Large Workpieces: Best for handling large, heavy workpieces requiring precise hole boring.

- Specific Boring Tasks: Ideal for applications focused solely on boring operations with high accuracy and depth control.

Conclusion

CNC machine centers offer significant benefits over CNC boring mills, especially in terms of versatility, efficiency, and multi-functionality. As a premier CNC machine manufacturer, Weish CNC provides advanced machining solutions tailored to meet the diverse needs of various industries.

By choosing a CNC machine center, businesses can achieve higher precision, reduced setup times, and improved overall efficiency. Contact Weish CNC today to learn more about our state-of-the-art CNC machine centers and discover how our expertise can help you achieve superior results with excellent cost performance. Experience the quality and innovation that only a leading CNC machine manufacturer from China can offer.