The Versatility And Applications Of CNC Boring Mill

CNC boring mill is a widely used machine tool used in various industries for precise and efficient operation of large workpieces. They can handle various materials, including metals, plastics, composite materials, etc. The versatility of CNC boring mill lies in their ability to perform various types of machining processes.

It has a main axis that moves along a horizontal plane, which we use to cut materials in various ways. Contains multi-layer cutting heads, perfect for creating complex parts. One of the most common uses is to create precise holes for inserting screws, nuts, and bolts. CNC boring mill can process various sizes of holes from very small to very large. It can also be used to create shapes such as circular and square holes.

CNC boring mill can also be used to punch holes, form grooves, surfaces, and threaded holes on parts. It can also be used for drilling threaded holes and reaming. By combining these operations, complex parts, such as mechanical components, can be processed quickly and accurately.

In addition, it can also be used for drilling and tapping. Use the drilling machine by setting the required hole coordinates and depth. Then use a tap to tap the thread on the drilling hole. By using a CNC boring mill, matching holes can be quickly and accurately created.

Where is the universality of CNC boring mill reflected? Here’s a detailed introduction

Boring:

As the name suggests, CNC boring mills excel in boring machine operations, including expanding or finishing existing holes on workpieces. They are typically used to produce precision holes with high precision and surface finish, which is crucial in applications that require strict tolerances.

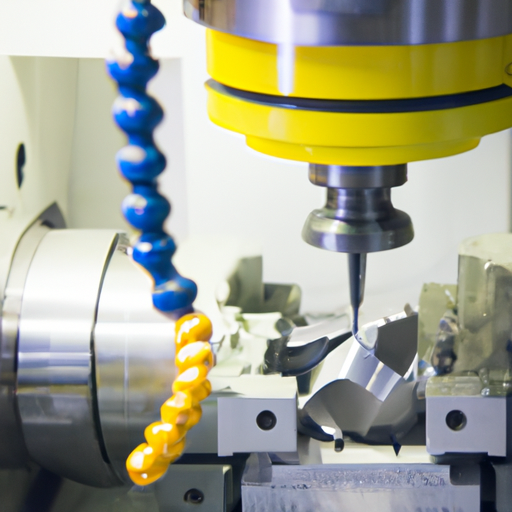

Milling:

CNC boring mills can perform milling operations, including end milling, contour milling, and slotting. They can create complex shapes and contours on large workpieces, making them suitable for manufacturing components such as molds, molds, and aerospace parts.

Drilling:

In addition to boring machines, CNC boring mills can also drill holes on workpieces. This feature is suitable for tasks that require precise placement and size adjustment of holes.

Tapping:

CNC boring mill can also perform tapping operations to form internal threads in the workpiece. This is particularly useful for creating threaded holes in large components used in various industries.

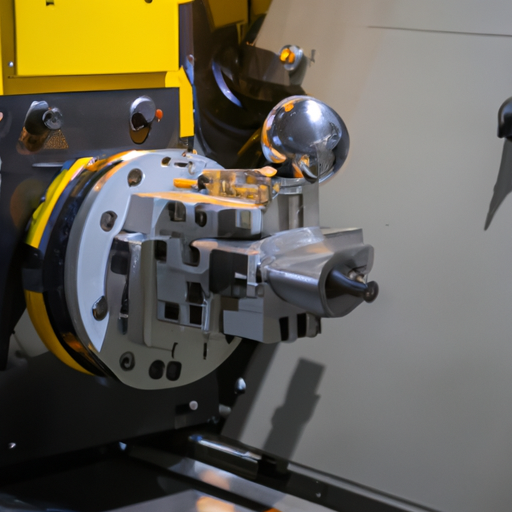

Turning:

Some CNC boring mills are equipped with optional turning functions, allowing them to rotate cylindrical workpieces. This enhances their functionality and makes them more versatile in certain applications.

The application of CNC boring mill is also very extensive. Below is a brief introduction to some common industries:

- Aerospace industry:

CNC boring mills are widely used in the aerospace industry to manufacture large aircraft components, such as engine casings, landing gear components, and structural components. - Automotive industry:

In the automotive industry, CNC boring machines are used to process engine cylinder blocks, transmission housings, and other key components. Their ability to handle large workpieces and perform precise operations helps improve the efficiency and reliability of automotive systems. - Oil and Gas Industry:

CNC boring mills are used to manufacture parts for the oil and gas industry, including drilling equipment, valves, and pump components. - Heavy machinery manufacturing:

Heavy machinery and equipment manufacturers often use CNC boring mill to manufacture large parts, such as gear boxes, turbines and industrial Machine element. - Tool and mold manufacturing:

In tool and mold manufacturing, CNC boring mill can process complex details and maintain strict tolerances, which helps to achieve high-quality output of these components.

CNC boring mill play a crucial role in modern manufacturing, from creating complex shapes to improving structural integrity. CNC boring mills are essential equipment in any mechanical workshop.

Weish CNC MASTER is a professional CNC machine manufacturer concentrating all its resources on developing and building CNC 5 axis gantry milling machine, CNC boring mill,router machine and CNC vertical lathe with C axis. Ever since its early days, Weish CNC has operated with “elitism ” as its business philosophy, focusing upon efficient management of human resources.