In the manufacturing world, accuracy is one of the most critical factors for success. Whether you are manufacturing complex parts for aerospace or components for heavy machinery, accurate and efficient processing capabilities are crucial. CNC vertical lathe provide a vertical machining method that is changing industries around the world

CNC vertical lathe, also known as vertical turning center, is a specialized machine designed for precision machining of large and usually heavy workpieces. Unlike traditional horizontal lathes, CNC vertical lathes install and rotate the workpiece horizontally, while CNC vertical lathes fix the workpiece on a vertical spindle.

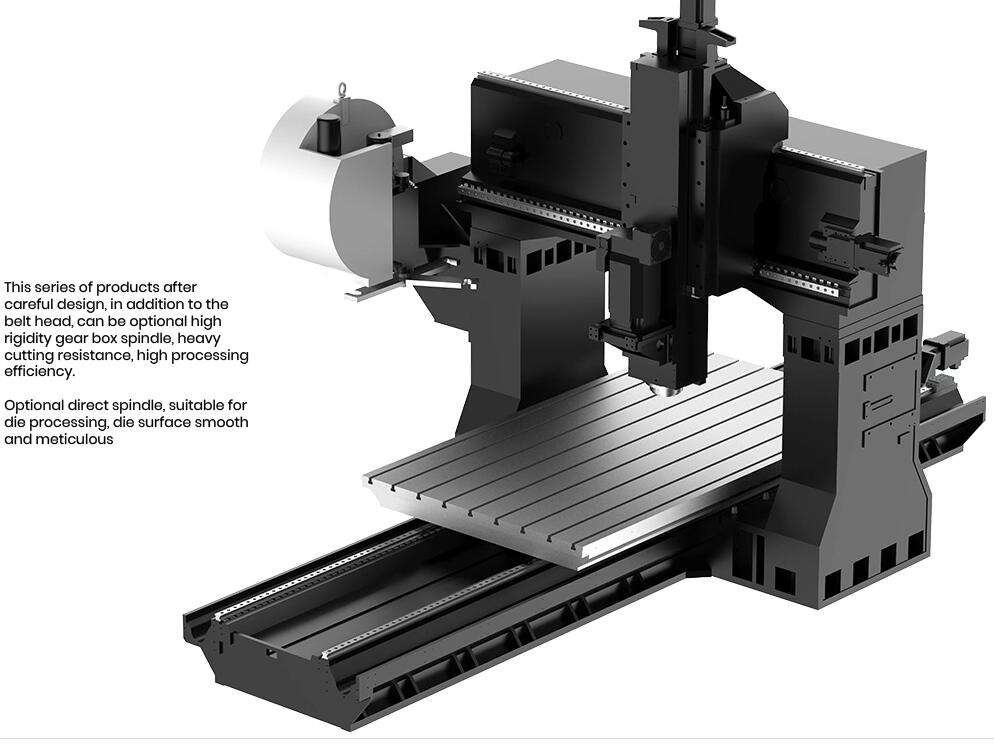

Key components:

Vertical spindle: The core of a CNC vertical lathe, which fixes and rotates the workpiece during the machining process.

Tool holder: The tool holder accommodates various cutting tools and allows for multiple operations without the need for manual tool replacement.

Control system: Modern CNC vertical lathes are equipped with a computer numerical control system, which can accurately control the speed of the cutting tool, spindle, and feed rate.

Chuck or workpiece fixing device: During the machining process, this component can firmly fix the workpiece in place.

Cross guide rail: Many CNC vertical lathes have a movable cross guide rail that can adjust the height of the tool holder to adapt to different workpiece sizes.

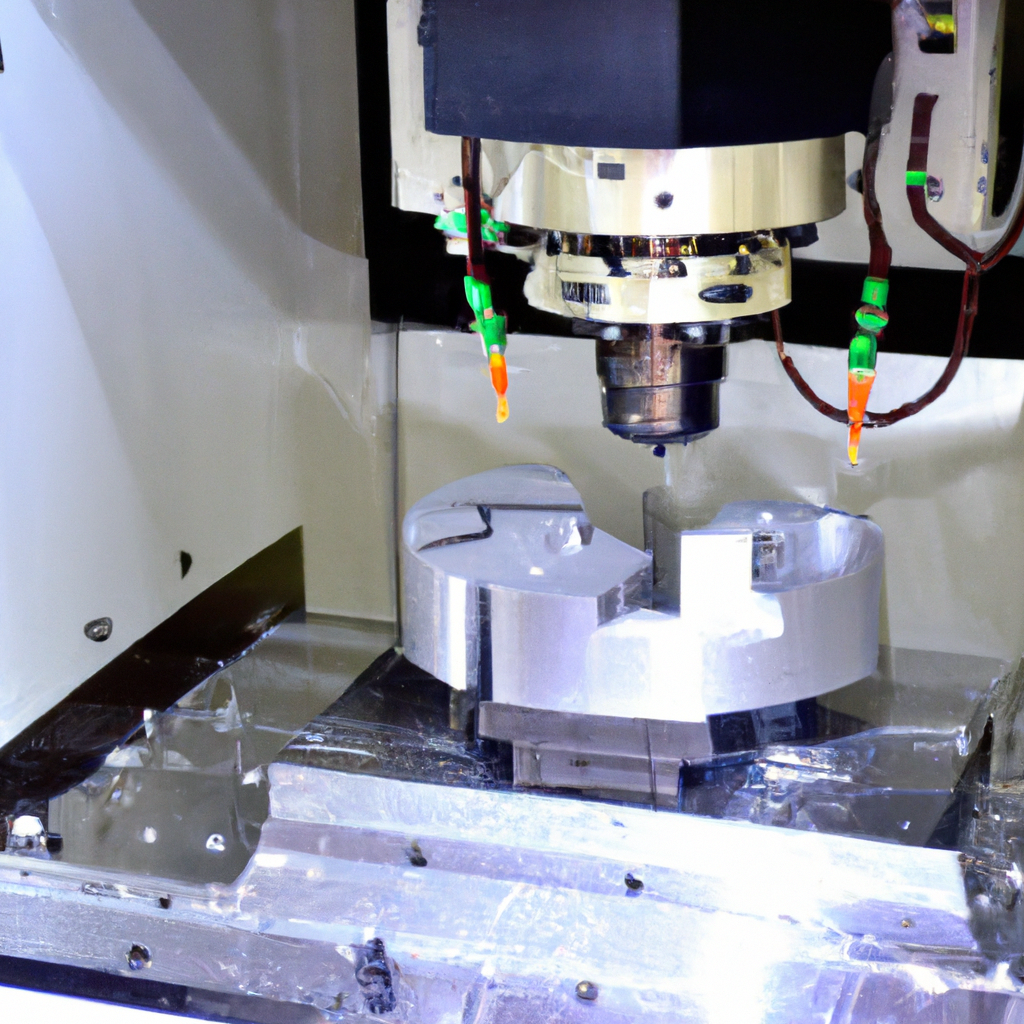

Lathe process:

Workpiece setting: The operator uses a chuck or other workpiece fixing device to fix the workpiece on the vertical spindle.

Tool selection: Select the appropriate cutting tool and load it into the tool turntable.

Programming: CNC operators or programmers create machining programs that specify tool paths, cutting speeds, and other parameters.

Processing: The spindle of a CNC vertical lathe rotates the workpiece, while the tool holder moves along the vertical axis to perform various cutting operations, such as turning, drilling, and milling.

Precision control: The CNC system precisely controls the motion of the cutting tool, ensuring that the workpiece is processed to the required specifications with extraordinary precision.

Advantages:

Improving accuracy: Vertical lathes excel in achieving high accuracy and are an ideal choice for manufacturing key components.

Universality: CNC vertical lathes can handle workpieces of various sizes and shapes.

Efficiency: Multiple operations can be performed without the need for manual tool replacement, reducing processing time.

Space saving: Vertical lathes typically require less space than horizontal lathes.

Application:

Aerospace: CNC vertical lathes are used for precision machining of large aircraft components.

Automobiles: They play a crucial role in the production of engine and transmission components.

Energy: Vertical lathes are used for power generation and component production in the oil and gas industry.

Universal manufacturing: These machines have a wide range of uses and can meet the needs of various industries, producing parts for machinery, construction equipment, and other related industries.

CNC vertical lathe is a technological miracle that redefines precision machining. Its vertical orientation, combined with advanced CNC control, provides unparalleled accuracy and efficiency in the manufacturing process.

Weish CNC MASTER is a professional CNC machine manufacturer concentrating all its resources on developing and building CNC 5 axis gantry milling machine, CNC boring mill,router machine and CNC vertical lathe with C axis. Ever since its early days, Weish CNC has operated with “elitism ” as its business philosophy, focusing upon efficient management of human resources.