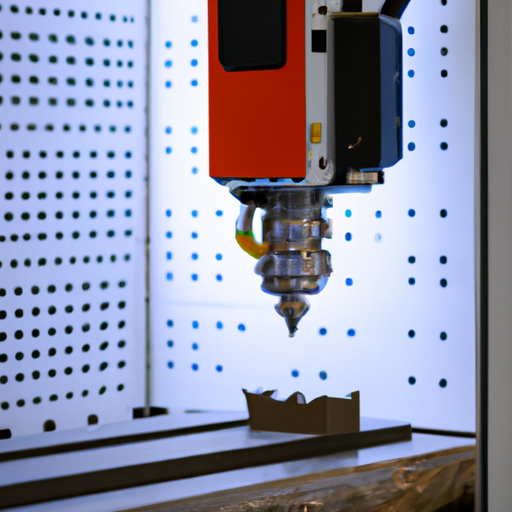

contract cnc machining

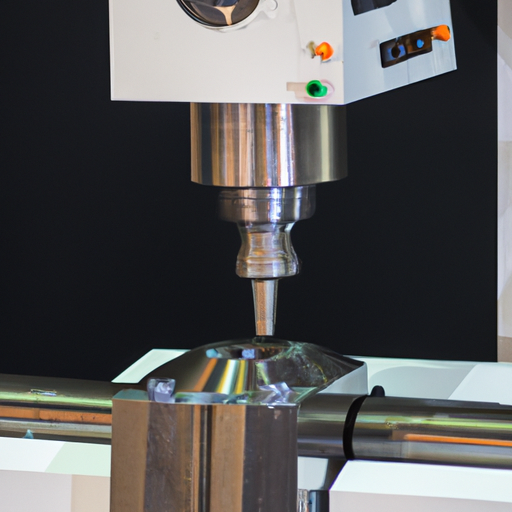

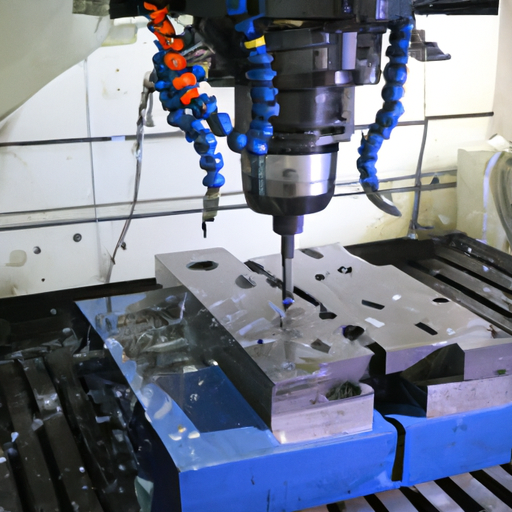

The spindle adopts Taiwan spindle

The feed motor adopts FANUC original motor

The spindle motor adopts FANUC original motor

The X-axis screw adopts the Spanish ipiranga European standard IT5 level

Y/Z axis screw adopts Japanese THK precision grinding C3 level

The guide rail adopts the silver roller P grade precision

The bearing adopts Japanese NSK precision P4 bearing

Description

WEISH CNC MASTER is located in Ningbo City, Zhejiang Province. We have always been devoted to the research and manufacture of CNC machines. We have R & D Production Department, Quality Control Department, and Sales & Service Department. Our products are widely used in machinery,automobile,weapons,shipbuilding,aerospace,steel,energy,printing and so on.

We can offer you high quality products with the competitive price. Our products got the CE certificate. Our main products are double column lathe,horizontal boring machine(table type),5 axis machining center,Vertical lathe,CNC machine center,floor type boring,CNC gantry milling machine,CNC vertical lathe,5 Axis Milling Head A/C,Router machine and so on. With advanced technology, high quality, reasonable price and perfect post-sales service, our products have attained favorable comments among other our clients and our business has developed rapidly.

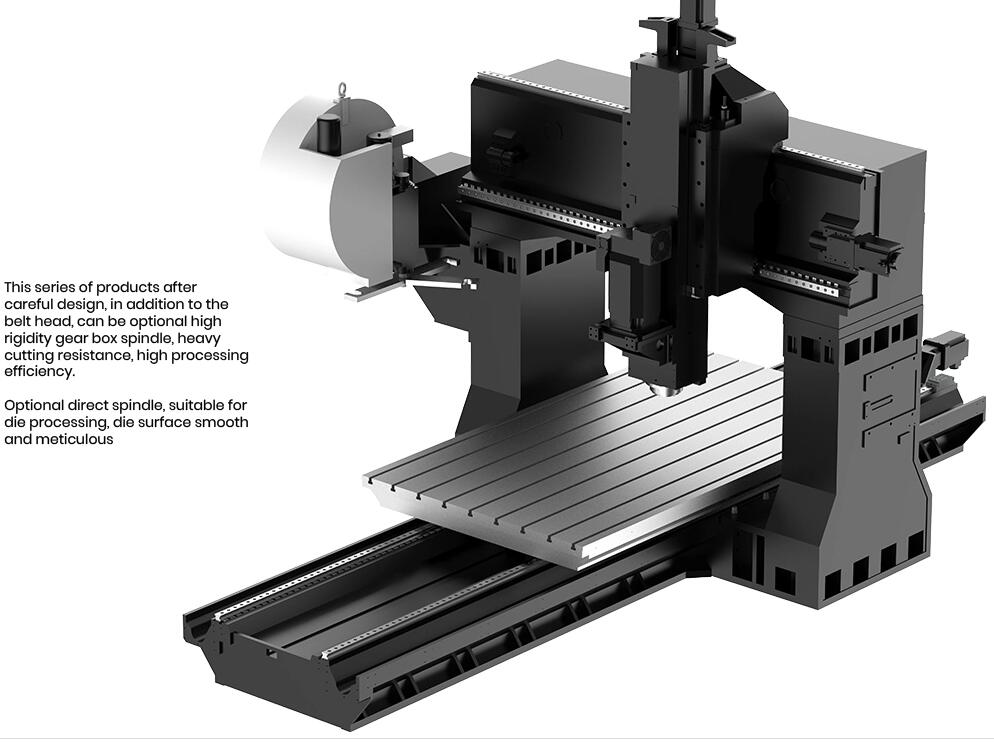

contract cnc machining produced by WEISH CNC MASTER uses a gantry to move on the base, and the workbench is fixed between 2 columns. It occupies a small area and the user’s investment cost is low. The processing height can be determined by the height of the mud when the user installs.

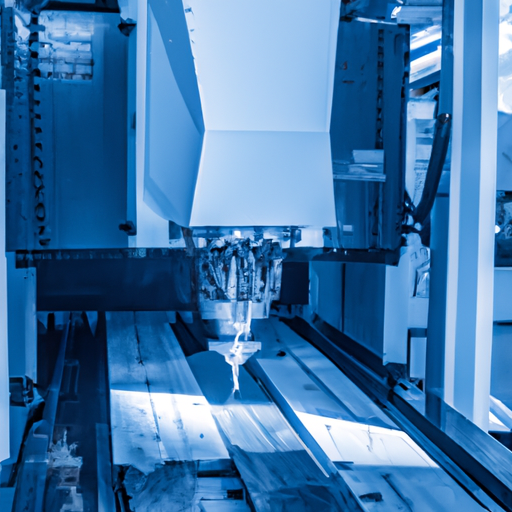

It has the characteristics of strong vibration absorption,good dynamic characteristics,high rigidity,high precision,large torque,heavy cutting. The machine tool’s technical indicators and configuration are domestically leading, its product structure and technology are mature, and its product quality is stable.

Beam: Strengthen structure. HT300

Main spindle motor: Original SIEMENS AC motor

Linear Guideway: #65

5 Axis head: MEPRO / Optional

Y1 and Y2 axis ball screw: 80mm

Bearing: FAG Germany / NSK Japan

Couping: NBK Japan

Reducing: ALPHA Germany

CNC SYSTEM:SIEMENS 840D

X.Y.Z.C.A is 5 axis linkage controlled by system. Table fixed and column moving. Cross beam fixed

1:The seller(WEISH CNC MASTER) will dispatch technicians to the customer’s designated location for installation and debugging based on customer needs. Includes Training, commissioning and programming

2:we can provide the remote training if customer don’t need the on-site installation

3:promise to replace the broken part of machine during the warranty period

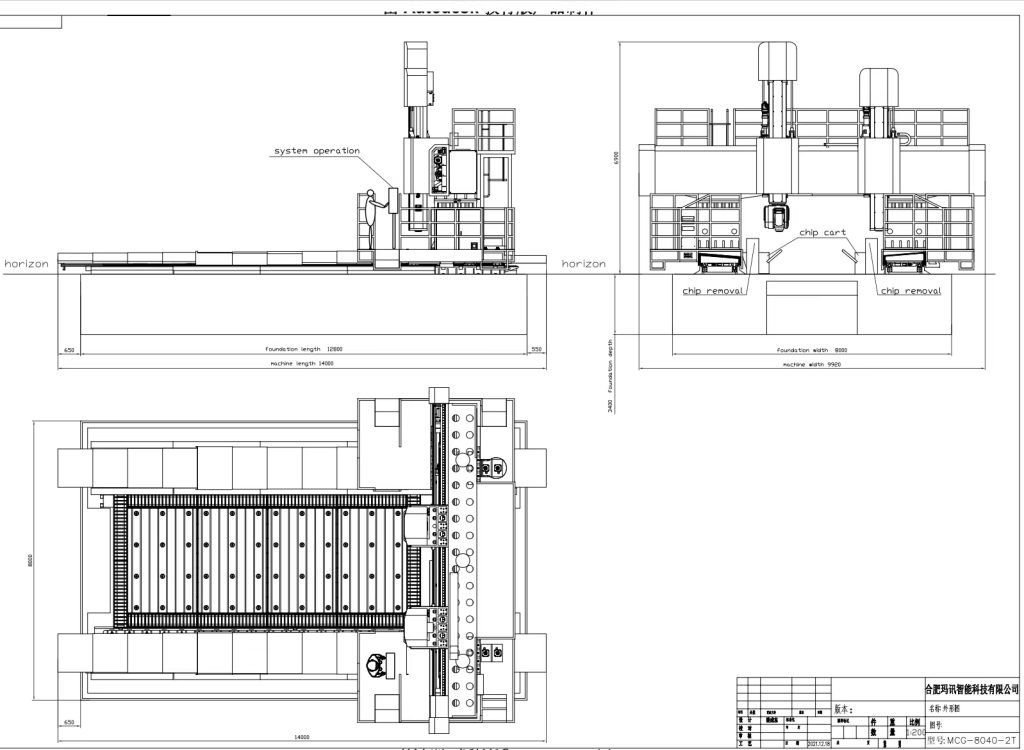

| # | Parameter | Information |

|---|---|---|

| 1 | Product Name | contract cnc machining |

| 2 | Product Type | CNC machine |

| 3 | Place of Origin | China |

| 4 | Brand Name | WEISH CNC MASTER |

| 5 | Motor power(KW) | 25 |

| 6 | COLORS | White+Customizable |

| 7 | Spindle speed (rpm) | 10-6000 |

| 8 | Size(CM) | 643*227*245 (Please consult us for specific details) |

| 9 | Export Region | Oceania,America,Africa… |

| 10 | Export Countries | Russia,India,Nicaragua,Maldives,Honduras…etc |

| 11 | Control system | Fagor control system |

| 12 | Condition | New |

| 13 | CNC or Not | CNC |

| 14 | Warranty | 1+Year |

| 15 | Machinery Test Report | Provided |

| 16 | Video outgoing-inspection | Provided |

| 17 | Core Components | Gear,Motor,Bearing |

| 18 | Packaging Details | 5×40″OT for loading |

| 19 | Lead time (days) | 25-30(To be negotiated) |

Please note: This table is for reference only, please consult us for specific information.

contract cnc machining–A Guide to Frequently Asked Questions

2.What are the product skill training options?

3.Does the contract cnc machining have remote monitoring and diagnostic capabilities?

4.How many axes does contract cnc machining device typically have?

5.Development status of contract cnc machining industry

6.Does the contract cnc machining have a programmable control system and how to program it?

7.What are the different sizes and models of contract cnc machining available?

8.What industrial areas is the contract cnc machining suitable for?

9.Where is your factory located? How can I visit there?

10.What are the dimensions and load-bearing capacity of the workbench of the contract cnc machining?

1.What is the difference between a contract cnc machining? and cnc gantry machining center?

Table moving, column fixed. Table fixed, column moving, Cross beam fixed, Cross beam moving.The difference between a CNC machining center and a CNC machine tool is that the machining center adds an automatic tool changing system to the CNC machine tool, which is a CNC machine tool with a tool magazine.

CNC gantry milling machines mainly use milling cutters to shape the surface of the workpiece, which requires sufficient rigidity. Boring machines mainly use boring tools to process pre-made holes in workpieces to certain requirements, requiring sufficient accuracy.

2.What are the product skill training options?

WEISH CNC MASTER provide Installation training, operation training, Programming training.

3.Does the contract cnc machining have remote monitoring and diagnostic capabilities?

Yes.

(1) Online collection technology of high-end CNC machine tool working status information;

(2) Monitoring signal extraction and identification;

(3) Intelligent fusion technology of multi-sensor information;

(4) Research on the failure mechanism of key components;

(5) Real-time online display of CNC machine tool processing status;

(6) Intelligent fault warning and diagnosis technology;

(7) Seamless integration of fault prediction system and MES system.

4.How many axes does contract cnc machining device typically have?

3 axis , 3+2 axis, 5 axis. Up to client’s reqirement

5.Development status of contract cnc machining industry

The application of contract cnc machining technology has penetrated into various fields and has become an important part of manufacturing production. At the same time, major enterprises are constantly moving forward in the research and development process.

Practice has shown that the application of contract cnc machining technology can greatly improve the accuracy and efficiency of part production, reduce cutting costs, and thus effectively improve the operational efficiency of enterprises. and competitiveness.

6.Does the contract cnc machining have a programmable control system and how to program it?

Yes. SIEMENS 828D.840D./ FANUC / GSK. 1:Tool radius compensation function (G40, G41, G42) 2:Programming incrementally. 3:Programming in absolute terms.

7.What are the different sizes and models of contract cnc machining available?

WEISH CNC MASTER make the gantry milling machine in Professional customization

8.What industrial areas is the contract cnc machining suitable for?

Mainly suitable for various plane milling of large metal parts. For example: steel, energy, chemical industry, bridges, railways, automobiles, military molds and machinery industries. It can realize the automation of processing machine tools and production processes.

9.Where is your factory located? How can I visit there?

Our factory is located in Ningbo City ,Zhejiang Province,China. You are warmly welcomed to visit us.

10.What are the dimensions and load-bearing capacity of the workbench of the contract cnc machining?

Table size is Up to client’s requirement. Worktable loading is from 30-150 Tons

Tags:kuraki cnc machine,desktop cnc milling machine kit,hermle cnc machine,cnc machine control panel