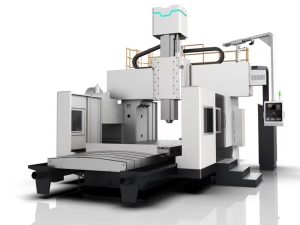

CNC gantry machining center for 5 axis large

We make this type customerized up to our clients

Description

DHX series gantry machine uses a gantry to move on the base, and the workbench is fixed between 2 columns. It occupies a small area and the user’s investment cost is low. The processing height can be determined by the height of the mud when the user installs. The gantry is moved by screw drives on both sides , The guide rail adopts the silver roller linear guide, the screw adopts Japanese THK, the double drive motor adopts the absolute encoder motor, the FANUC original motor, does not need to be turned on to return to zero, the power is cut off, and the original processing point can be found at will to continue processing, saving users time

| Item | Name | Brand | Remark | ||||

| 1 | ATC | OKADA TAIWAN | Optional | ||||

| 2 | Feeding motor | FANUC | X axis 36NM two double drives, YZ axis torque 36NM, Z axis with brake | ||||

| 3 | Main motor | FANUC | 22/26KW | ||||

| 4 | System | FANUC OIMF | |||||

| 5 | X-Screw | Ipiranga Spain | IT5 | ||||

| Y/Z Screw | THK | C3, | |||||

| 6 | Bearing | NSK | P4 | ||||

| 7 | Electric part | ||||||

| 8 | Leaner guideway | HIWIN Taiwan | 55 rollers | ||||

| 9 | encoder | Absolute encoder | No need to return to the origin | ||||

| 10 | Guideway | HIWIN Taiwan | 55 roller | ||||

| 11 | Main spindle | MicroLab Taiwan | |||||

| Item | |||||||

| 1 | X travel | mm | 12000 | ||||

| 2 | Y travel | mm | 4400 | ||||

| 3 | Z travel | mm | 1200 | ||||

| 4 | Between column | mm | 4200 | ||||

| 5 | Distance from spindle end to worktable | mm | 600-1800 | ||||

| 6 | Worktable size | mm | 8000*3000 | ||||

| 7 | Max loading | T | 8/M2 | ||||

| 8 | T slot | No. | 28 | ||||

| 9 | T-slot size/spacing | mm | 28/250 | ||||

| 10 | Spindle drive mode | Direct drive | |||||

| 11 | Spindle speed | rpm | 10-6000 | ||||

| 12 | Motor power | kW | 22/26 | ||||

| 13 | Spindle torque | N.m | 170+BFGear box 680NM | ||||

| 14 | Spindle taper | ISO7:24NO50 | |||||

| 15 | Pull nail specifications | P50T-2-MAS503 | |||||

| 16 | Spindle dia | mm | Φ190 | ||||

| 17 | X、Y、Z Rapid move | m/min | 7/7/7 | ||||

| 18 | X、Y、Z servo motor | kW | 5.2*2/5.2/5.2 | ||||

| 19 | X、Y、Z servo torque | N.m | X-36*4,YZ-36*3/36*3 | ||||

| 20 | X、Y、Z servo motor | rpm | 3000 | ||||

| 21 | X/Y/Z Dia of Screw | mm | Φ10020/8020/Φ6320 | ||||

| 22 | Feeding speed | mm/min | 6000 | ||||

The spindle adopts Taiwan spindle

Feed motor absolute encoder motor

The feed motor adopts FANUC original motor

The spindle motor adopts FANUC original motor

The X-axis screw adopts the Spanish ipiranga European standard IT5 level

Y/Z axis screw adopts Japanese THK precision grinding C3 level

The guide rail adopts the silver roller P grade precision

The bearing adopts Japanese NSK precision P4 bearing

The system uses Siemens 828D/FAUNC OI

10020 screw double drive transmission for X axis

Crossbeam Japan THK screw drive

The castings are made of high-grade resin sand HT250, with secondary tempering

You must be logged in to post a review.

Reviews

There are no reviews yet.