brass cnc machining parts

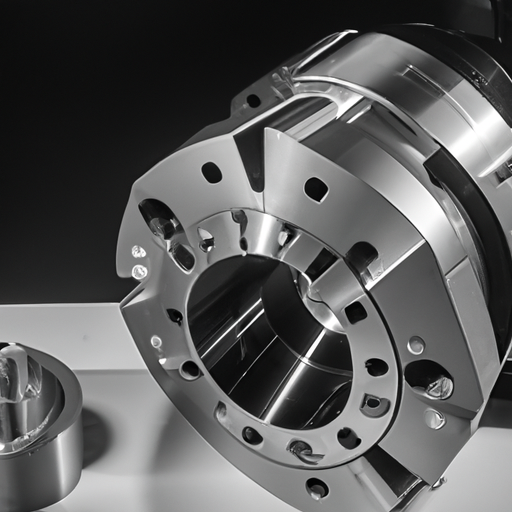

The spindle adopts Taiwan spindle

The feed motor adopts FANUC original motor

The spindle motor adopts FANUC original motor

The X-axis screw adopts the Spanish ipiranga European standard IT5 level

Y/Z axis screw adopts Japanese THK precision grinding C3 level

The guide rail adopts the silver roller P grade precision

The bearing adopts Japanese NSK precision P4 bearing

Description

Weish CNC Machine Master specializes in the design, development, production, and sales of CNC machine. We have established a world leading standard workshop and multiple automated production lines. Passed the ISO quality management system and environmental management system, and obtained multiple product certifications such as CE. Our machines have been exported to Russia, India, South Africa, Vietnam, Peru, the United States, and Algeria,Luxembourg,etc.

The design and manufacture of brass cnc machining parts comply with ISO international standards, and the units of measurement for all parts of the machine tools and various instruments all adopt international unit standards.

CNC machining of precision parts, workpiece clamping can complete milling,tapping,boring,reaming Various processes such as silk are processed.

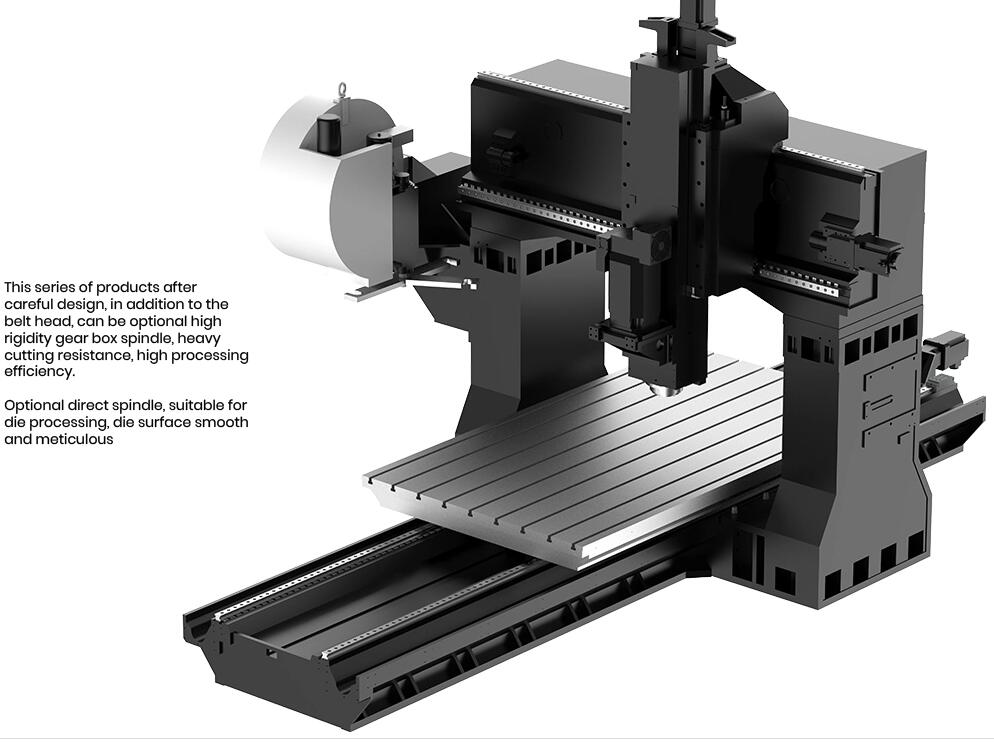

Beam: Strengthen structure. HT300

Main spindle motor: Original SIEMENS AC motor

Linear Guideway: #65

5 Axis head: MEPRO / Optional

Y1 and Y2 axis ball screw: 80mm

Bearing: FAG Germany / NSK Japan

Couping: NBK Japan

Reducing: ALPHA Germany

CNC SYSTEM:SIEMENS 840D

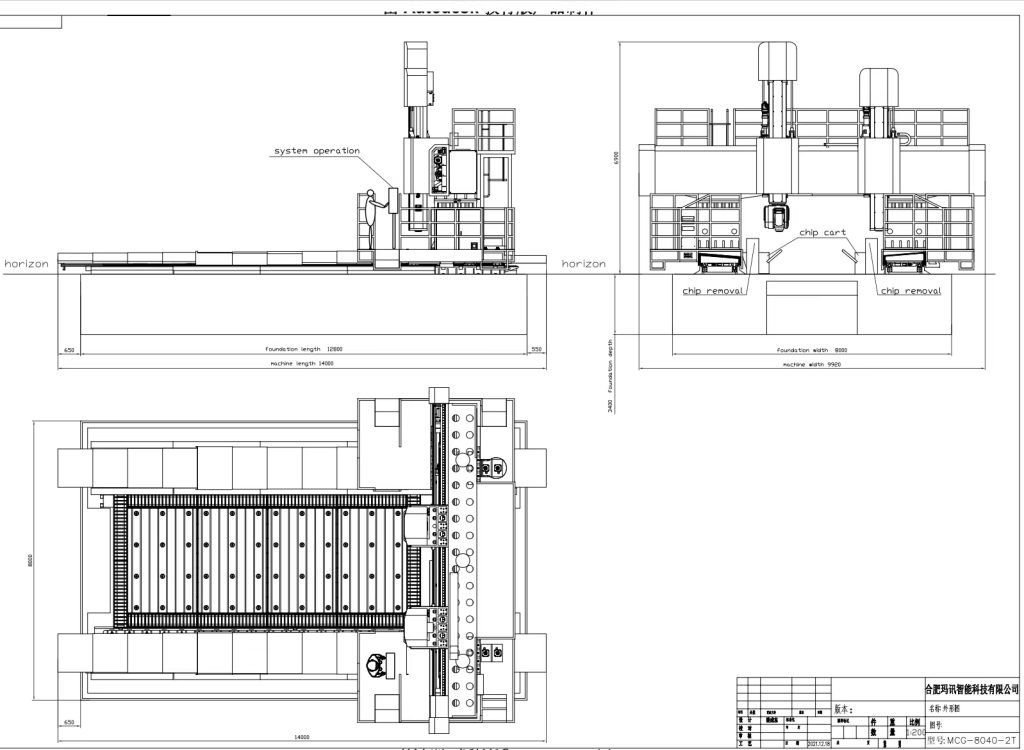

X.Y.Z.C.A is 5 axis linkage controlled by system. Table moving and column fixed Cross beam fixed

1:The seller(WEISH CNC MASTER) will dispatch technicians to the customer’s designated location for installation and debugging based on customer needs. Includes Training, commissioning and programming

2:we can provide the remote training if customer don’t need the on-site installation

3:promise to replace the broken part of machine during the warranty period

| # | Parameter | Information |

|---|---|---|

| 1 | Product Name | brass cnc machining parts |

| 2 | Product Type | CNC machine |

| 3 | Place of Origin | China |

| 4 | Brand Name | WEISH CNC MASTER |

| 5 | Motor power(KW) | 25 |

| 6 | COLORS | Blue+Customizable |

| 7 | Spindle speed (rpm) | 10-6000 |

| 8 | Size(CM) | 757*176*240 (Please consult us for specific details) |

| 9 | Export Region | Africa,Asia,America… |

| 10 | Export Countries | Russia,India,Belarus,Thailand,Philippines…etc |

| 11 | Control system | Haas control system |

| 12 | Condition | New |

| 13 | CNC or Not | CNC |

| 14 | Warranty | 1+Year |

| 15 | Machinery Test Report | Provided |

| 16 | Video outgoing-inspection | Provided |

| 17 | Core Components | Engine,Pump,Bearing |

| 18 | Packaging Details | 5×40″OT for loading |

| 19 | Lead time (days) | 25-30(To be negotiated) |

Please note: This table is for reference only, please consult us for specific information.

brass cnc machining parts–A Guide to Frequently Asked Questions

2.Does the brass cnc machining parts support High Speed Machining?

3.What type of material can the brass cnc machining parts process?

4.Does the brass cnc machining parts have a cooling system to control temperature?

5.Is the brass cnc machining parts equipped with a tool and workpiece clamping system?

6.Where is your factory located? How can I visit there?

7.What are the advantages of brass cnc machining parts technology?

8.brass cnc machining parts manufacturer service and quality system

9.What are the different sizes and models of brass cnc machining parts available?

10.How automated and intelligent is the brass cnc machining parts?

11.What are the dimensions and load-bearing capacity of the workbench of the brass cnc machining parts?

12.About brass cnc machining parts,What is the delivery time?

13.How does gantry milling machine compare to other Gantry Machining Center technologies?

14.Does the brass cnc machining parts have an automatic measurement and calibration system?

15.What is the working accuracy of the brass cnc machining parts?

16.What are the sustainability and environmental characteristics of the brass cnc machining parts?

1.About brass cnc machining parts,Do you have any certificates?

Yes, our machine is CE-compliant, and our factory is ISO 9001 accredited.

2.Does the brass cnc machining parts support High Speed Machining?

Yes.Cutting speed:10-10000mm/min

3.What type of material can the brass cnc machining parts process?

Stainless steel, cast iron, copper, aluminum

4.Does the brass cnc machining parts have a cooling system to control temperature?

Yes. Lubricate system. Cutting oil temp control system

5.Is the brass cnc machining parts equipped with a tool and workpiece clamping system?

Yes. Hydraulic chuck

6.Where is your factory located? How can I visit there?

Our factory is located in Ningbo City ,Zhejiang Province,China. You are warmly welcomed to visit us.

7.What are the advantages of brass cnc machining parts technology?

brass cnc machining parts can effectively reduce the processing time and auxiliary time of parts. The CNC machine tool has a wide range of spindle speed and feed rate, allowing the machine tool to perform powerful cutting with large cutting volumes, rapid movement and positioning of CNC machine tool moving parts, and high-speed cutting, reducing the inter-process turnover time of semi-finished products and improving production efficiency.

8.brass cnc machining parts manufacturer service and quality system

WEISH CNC MASTER has a highly skilled and experienced R&D team that can carry out customized design and manufacturing according to customer needs. The company’s products adopt advanced numerical control systems and electronic control systems, which have the advantages of high precision, high stability, and high efficiency. In addition, the company also has a complete after-sales service system that can provide customers with a full range of technical support and services.

9.What are the different sizes and models of brass cnc machining parts available?

WEISH CNC MASTER make the gantry milling machine in Professional customization

10.How automated and intelligent is the brass cnc machining parts?

As the development of high technology becomes more intense, high-tech elements will also be used in the processing and manufacturing of various cargo facilities, which can not only give them special operational power but also improve the overall visual effect.

In fact, if we observe the pentahedral machining center, we can also understand what kind of application effects it shows when high-tech elements are used on it. As a kind of processing facility that has attracted much attention from compatriots, after the pentahedral machining center appeared on the market, the changes it brought to many processing and manufacturing companies cannot be ignored.

As people pay more attention to the goods of the facility, more and more people Many new manufacturing processes are also used in pentahedral machining centers.

11.What are the dimensions and load-bearing capacity of the workbench of the brass cnc machining parts?

Table size is Up to client’s requirement. Worktable loading is from 30-150 Tons

12.About brass cnc machining parts,What is the delivery time?

The full series of standard models are in stock. For a customized one, it depends.

13.How does gantry milling machine compare to other Gantry Machining Center technologies?

WEISH CNC MASTER use high-strength machine tool castings to maintain good rigidity during processing.

14.Does the brass cnc machining parts have an automatic measurement and calibration system?

brass cnc machining parts adopts a modular design and can provide customers with different configurations according to specific needs, including on-machine measurement of workpiece contour thickness, 3D precision automatic calibration, online workpiece monitoring, chain tool magazine, and online monitoring; optional high-performance Siemens system and autonomous controllable CNC systems.

15.What is the working accuracy of the brass cnc machining parts?

X/Y/Z positioning accuracy:0.025mm X/Y/Z re-positioning accuracy:0.015mm

16.What are the sustainability and environmental characteristics of the brass cnc machining parts?

The spiral chip conveyors on both sides of the processing area quickly transport the iron chips generated by high-speed machining to the lifting chip conveyor, reducing thermal deformation of the machine tool and ensuring the accuracy and stability of the chip conveyor on both sides of the machine bed; the chip conveyor is equipped with an automatic oil-water separation device, which has an environmentally friendly effect good.

Tags:cnc machine leveling pads,cnc machining san diego,samsung cnc machine,nc and cnc machine