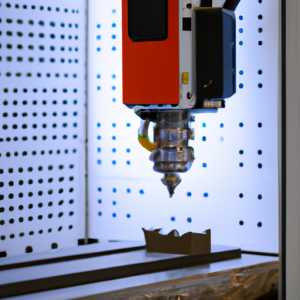

What Is Tool Offset and Why Is It Important in CNC Boring Mills?

Tool offset in CNC boring mills is a crucial parameter that ensures accurate machining by compensating for the size and wear of the tool. Weish, a reputable CNC machine manufacturer, explains that tool offset allows operators to adjust the tool’s position relative to the workpiece, ensuring precise cuts and reducing the risk of errors. Without proper management of tool offset, even small deviations can lead to poor part quality, excessive wear on the tool, and wasted materials.

In CNC boring mill operations, tool offset compensates for variables such as tool length, diameter, and wear. By inputting the correct tool offset values into the CNC control system, operators ensure that the tool interacts with the workpiece exactly as designed, achieving the desired tolerances and surface finish. Proper management of tool offset is essential in industries like aerospace, automotive, and heavy machinery manufacturing, where precision is paramount.

How Do You Manage Tool Offset in CNC Boring Mill Operations?

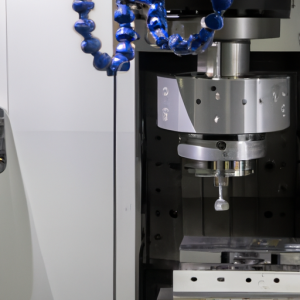

Managing tool offset in CNC boring mills requires attention to detail and a systematic approach. Operators need to measure the tool accurately before inputting the offset values into the CNC system. This measurement is critical because any discrepancy between the actual tool dimensions and the programmed values can result in poor machining performance. Weish recommends using advanced tool measurement devices like touch probes and laser systems to ensure high precision.

Once the tool dimensions are measured, operators can program the offset values into the machine. These values account for tool length, diameter, and the expected wear over time. As the tool wears, periodic adjustments to the offset may be necessary to maintain machining accuracy. Many modern CNC systems, including those supplied by Weish, have automated systems that can detect tool wear and make automatic adjustments to the offset, minimizing downtime and ensuring consistent output quality.

Another important aspect of tool offset management is maintaining a detailed log of all tool offsets and adjustments. This allows operators to track tool wear over time and optimize tool usage for better cost performance. In addition to manual adjustments, some CNC machines feature in-process measurement capabilities that automatically detect deviations and correct tool offsets in real time, ensuring continuous precision.

Advantages of Proper Tool Offset Management

Proper tool offset management provides several advantages, including improved part accuracy, reduced tool wear, and optimized machining efficiency. Weish, known for its high-quality CNC machines, emphasizes that accurate tool offset management results in fewer production errors, leading to lower scrap rates and higher productivity. This translates into better cost efficiency for manufacturers, especially those involved in high-precision manufacturing.

By maintaining accurate tool offsets, manufacturers can also extend the lifespan of cutting tools. Tools that are properly aligned and compensated for wear experience less stress, reducing the risk of premature failure. This not only lowers tooling costs but also reduces machine downtime associated with tool changes.

For OEM/ODM manufacturers and factories relying on CNC boring mills for custom part production, effective tool offset management is a key factor in achieving consistent product quality. Proper offset management ensures that the final products meet exact design specifications, boosting the reliability and reputation of the supplier. Additionally, Weish’s CNC machines are designed to facilitate easy tool offset adjustments, ensuring a smooth and efficient manufacturing process.

Conclusion

Managing tool offset in CNC boring mills is essential for maintaining precision, extending tool life, and optimizing overall machining performance. By accurately measuring tool dimensions and adjusting offsets as needed, operators can achieve high-quality machining results with fewer errors. Weish, a leading CNC machine manufacturer, provides advanced machines equipped with features that simplify tool offset management, enhancing both productivity and cost performance. For businesses seeking to maximize the efficiency of their CNC boring mills, proper tool offset management is a critical aspect of achieving reliable and consistent production outcomes.