cnc machine milling machine

Description

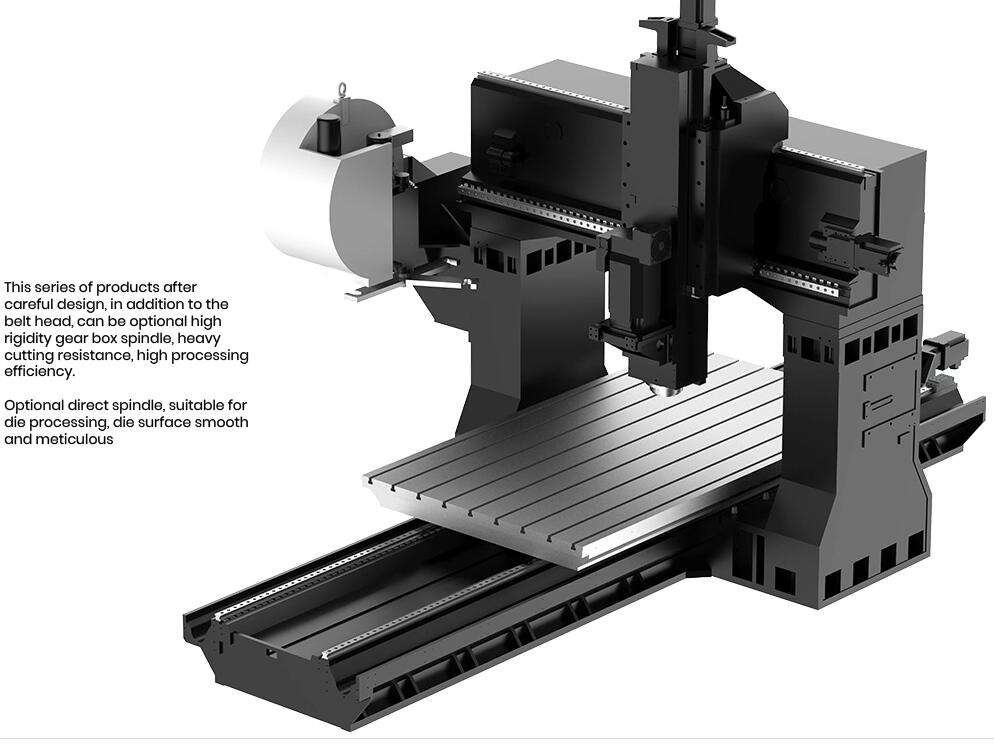

CNC machine milling machine uses a gantry to move on the base, and the workbench is fixed between two columns. It occupies a small area and the user’s investment cost is low. The processing height can be determined by the height of the mixed soil when the user installs it.

The two sides of the gantry are driven by screw rods, the guide rail adopts Shangyin roller linear guide, the screw rod adopts Japanese THK, the dual drive motor adopts absolute encoder motor, Siemens original motor, there is no need to start the machine to return to zero, and the original processing point can be found at will to continue processing when the power is turned off, saving users time.

1: Beam: Strengthen structure. HT300

2: Main spindle motor: Original SIEMENS AC motor

3: Linear Guideway: #65

4: 5 Axis head: MEPRO

5: Y1 and Y2 axis ball screw: 80mm

6: Bearing: FAG Germany

7: Couping: NBK Japan

8: Reducing: ALPHA Germany 9: CNC SYSTEM:SIEMENS 840D

X.Y.Z.C.A is 5 axis linkage controlled by system. Table moving and column fixed Cross beam fixed

1:The seller(WEISH CNC MASTER) will dispatch technicians to the customer’s designated location for installation and debugging based on customer needs. Includes Training,commissioning and programming

2:we can provide the remote training if customer don’t need the on-site installation

3:promise to replace the broken part of machine during the warranty period

1:High rigity of steel makes perfect work 2:High quality of iron casting. HT300 3:Ballscrew/bearing/Linear set from famous maker

4:Five-synchronous machining

5×40″OT for loading

30% TT prepaid.60% TT proceeding. 10% before shipment

cnc machine milling machine is produced in China

| # | cnc machine milling machine Parameter | Information |

|---|---|---|

| 1 | Motor power(kw) | 21 |

| 2 | Spindle speed (rpm) | 10-6000 |

| 3 | size(mm) | 16915*9136*8311 |

| 4 | color | blue |

| 5 | Control system | Fagor control system |

cnc machine milling machine–A Guide to Frequently Asked Questions

2.What are the security features of cnc gantry machining center?

3.Does the cnc machine milling machine have an automatic measurement and calibration system?

4.Development status of cnc machine milling machine industry

5.Does the gantry milling machine device have an automated loading and unloading system?

6.How fast does the cnc portal milling machine work?

7.What is the general power of the gantry milling machine spindle?

8.What is the capacity of portal milling machine tool magazine?

9.What are the product skill training options?

10.Does the cnc gantry milling machine have an automatic tool replacement feature?

11.How does gantry milling machine compare to other Gantry Machining Center technologies?

12.Does the gantry milling machine have a cooling system to control temperature?

13.What are the different sizes and models of gantry mills available?

14.Can the processing capacity of the gantry milling machine be expanded or customized?

15.What are the after-sales services available for gantry milling machine?

16.What is the production capacity of the factory for cnc gantry milling machine?

17.How automated and intelligent is the cnc machine milling machine?

18.Does the portal milling machine center have a programmable control system and how to program it?

1.How does the portal milling machine center ensure the safety of operators?

Yes

2.What are the security features of cnc gantry machining center?

Automatic power-off,Full loop protection , Crush detective system

3.Does the cnc machine milling machine have an automatic measurement and calibration system?

cnc machine milling machine adopts a modular design and can provide customers with different configurations according to specific needs, including on-machine measurement of workpiece contour thickness, 3D precision automatic calibration, online workpiece monitoring, chain tool magazine, and online monitoring; optional high-performance Siemens system and autonomous controllable CNC systems.

4.Development status of cnc machine milling machine industry

The application of CNC machining technology has penetrated into various fields and has become an important part of manufacturing production. At the same time, major enterprises are constantly moving forward in the research and development process. Practice has shown that the application of cnc machine milling machine technology can greatly improve the accuracy and efficiency of part production, reduce cutting costs, and thus effectively improve the operational efficiency of enterprises. and competitiveness.

5.Does the gantry milling machine device have an automated loading and unloading system?

Yes. Robot

6.How fast does the cnc portal milling machine work?

X/Y axis rapid feed speed:8000 rpm. Z axis rapid feed speed:8000 rpm. W axis rapid feed speed:2000 rpm.

7.What is the general power of the gantry milling machine spindle?

37-55KW

8.What is the capacity of portal milling machine tool magazine?

60 Tools

9.What are the product skill training options?

WEISH CNC MASTER provide Installation training, operation training, Programming training.

10.Does the cnc gantry milling machine have an automatic tool replacement feature?

Our machine can be equiped with ATC for tools and ATC for milling head

11.How does gantry milling machine compare to other Gantry Machining Center technologies?

WEISH CNC MASTER use high-strength machine tool castings to maintain good rigidity during processing

12.Does the gantry milling machine have a cooling system to control temperature?

Yes. Lubricate system. Cutting oil temp control system

13.What are the different sizes and models of gantry mills available?

WEISH CNC MASTER make the gantry milling machine in Professional customization

14.Can the processing capacity of the gantry milling machine be expanded or customized?

Yes. We can make the gantry milling machine in Professional customization

15.What are the after-sales services available for gantry milling machine?

Two-year warranty, Seller should assign 2 or 3 engineers come to clinet’s site for installation.

16.What is the production capacity of the factory for cnc gantry milling machine?

30 sets per year

17.How automated and intelligent is the cnc machine milling machine?

As the development of high technology becomes more intense, high-tech elements will also be used in the processing and manufacturing of various cargo facilities, which can not only give them special operational power but also improve the overall visual effect. In fact, if we observe the pentahedral machining center, we can also understand what kind of application effects it shows when high-tech elements are used on it. As a kind of processing facility that has attracted much attention from compatriots, after the pentahedral machining center appeared on the market, the changes it brought to many processing and manufacturing companies cannot be ignored. As people pay more attention to the goods of the facility, more and more people Many new manufacturing processes are also used in pentahedral machining centers.

18.Does the portal milling machine center have a programmable control system and how to program it?

Yes. SIEMENS 828D.840D./ FANUC / GSK. 1:Tool radius compensation function (G40, G41, G42) 2:Programming incrementally. 3:Programming in absolute terms.