Precision and accuracy are paramount in CNC machining, especially when it comes to complex operations like boring. Weish, a leading CNC machine manufacturer, specializes in the development and implementation of advanced programming techniques that enhance the accuracy of CNC boring mills. One such technique is absolute programming, which plays a critical role in ensuring precise and repeatable results. In this article, we explore the benefits of absolute programming and how Weish’s expertise can help you achieve superior accuracy in your machining operations.

What is Absolute Programming in CNC Boring Mills?

Absolute programming is a method used in CNC machining where all the coordinates for tool movements are specified relative to a fixed origin point, typically the zero point of the workpiece. This method contrasts with incremental programming, where each movement is specified relative to the previous position of the tool. Absolute programming ensures that each tool movement is precise and consistent, reducing the risk of cumulative errors that can occur with incremental programming.

Why is Absolute Programming Essential for Accuracy?

Accuracy in CNC boring operations is crucial for producing parts that meet exacting specifications, particularly when tight tolerances are required. Absolute programming enhances accuracy by eliminating the potential for errors that can arise from incorrect or inconsistent tool positioning. By referencing a fixed point for all movements, absolute programming ensures that each operation is performed with the highest level of precision, leading to better quality parts and less rework.

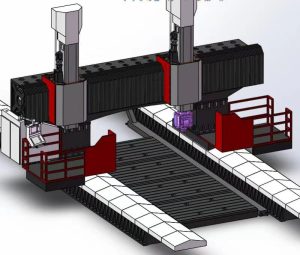

At Weish, we emphasize the importance of absolute programming in our CNC boring mills to deliver unmatched accuracy. Our CNC machines are equipped with the latest software and control systems that support absolute programming, allowing operators to achieve precise and reliable results in every operation.

How Does Weish Implement Absolute Programming in CNC Boring Mills?

Weish utilizes a combination of advanced technology, skilled programming, and rigorous testing to implement absolute programming in our CNC boring mills. Here’s how we ensure accuracy through this method:

Advanced CNC Control Systems

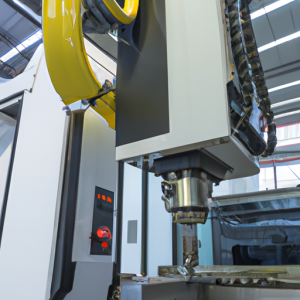

Weish’s CNC boring mills are equipped with cutting-edge control systems that support absolute programming. These systems allow operators to input precise coordinates and ensure that the machine executes each movement accurately. Our control systems are designed for ease of use, enabling operators to quickly set up and run programs with minimal risk of errors.

Precision Tooling and Fixturing

The accuracy of absolute programming also depends on the quality of the tooling and fixturing used in the operation. At Weish, we use high-precision tools and fixtures that are specifically designed for CNC boring. These tools and fixtures are calibrated to work seamlessly with our CNC control systems, ensuring that the programmed coordinates translate into accurate tool movements on the workpiece.

Operator Training and Expertise

Even with advanced technology, the skill and expertise of the operator play a crucial role in achieving accuracy. Weish provides comprehensive training to our operators on the principles and best practices of absolute programming. This training ensures that our team can effectively set up and execute programs that deliver precise and consistent results.

What Are the Benefits of Absolute Programming for CNC Boring Mills?

The use of absolute programming in CNC boring mills offers several key benefits:

- Enhanced Precision: By referencing a fixed origin point, absolute programming ensures that each tool movement is performed with high accuracy, leading to better part quality.

- Consistency: Absolute programming eliminates the risk of cumulative errors, ensuring that each part produced is consistent with the design specifications.

- Simplified Setup: With absolute programming, operators can easily set up and modify programs, reducing setup times and minimizing the risk of mistakes.

- Reduced Rework: The accuracy and consistency achieved through absolute programming reduce the need for rework, saving time and costs in the manufacturing process.

Why Choose Weish for CNC Boring Mills?

Weish is dedicated to providing our clients with the most accurate and reliable CNC machining solutions. Our commitment to using advanced techniques like absolute programming in our CNC boring mills sets us apart in the industry. Whether you are producing complex components or high-precision parts, Weish has the technology, expertise, and experience to meet your needs.

Partner with Weish for your CNC boring operations and experience the benefits of absolute programming for superior accuracy. Contact us today to learn more about our CNC machining capabilities and how we can help you achieve your manufacturing goals.