What Makes Gantry Milling Machines Different from Traditional Milling Machines?

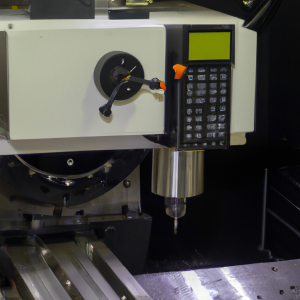

Gantry milling machines are designed with a unique structure that features a gantry frame with a bridge-type support system. This allows for better stability and a larger working area compared to traditional milling machines. Traditional milling machines typically have a C-frame design, which is more compact but may limit the size and scope of workpieces that can be handled. The gantry structure offers greater rigidity and precision, making it ideal for large-scale or complex machining tasks. Weish, a renowned CNC machine manufacturer, specializes in gantry milling machines that provide superior performance and efficiency for diverse industrial applications.

Are Gantry Milling Machines More Cost-Effective?

The cost-effectiveness of gantry milling machines depends on several factors, such as the nature of the work, material handling requirements, and production volume. Although gantry milling machines generally have a higher initial investment cost compared to traditional milling machines, their enhanced capabilities can lead to long-term cost savings. For example, gantry machines can handle larger workpieces and perform complex operations in a single setup, reducing the need for multiple machines or setups. This efficiency not only saves time but also lowers labor costs and minimizes material waste, making gantry milling machines a viable cost-effective option for certain machining operations.

Advantages of Gantry Milling Machines Over Traditional Milling Machines

Larger Work Area and Increased Capacity

One of the primary advantages of gantry milling machines is their ability to handle larger workpieces due to their expansive work area. Weish’s gantry milling machines are designed to accommodate oversized components, making them suitable for industries such as aerospace, automotive, and heavy equipment manufacturing. This capability allows for the machining of large parts in one continuous process, which would be challenging for traditional milling machines with limited workspace.

Superior Stability and Precision

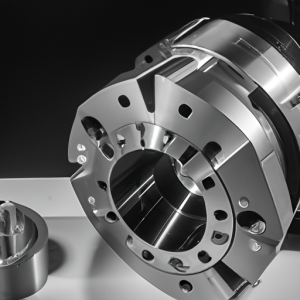

The gantry structure offers superior stability and rigidity compared to traditional milling machines. This stability ensures precise cutting, even when dealing with heavy-duty materials or complex geometries. Weish’s gantry milling machines are equipped with high-quality linear guides and ball screws that provide exceptional accuracy and repeatability, reducing errors and rework costs in production.

Versatility in Machining Applications

Gantry milling machines are versatile and can perform various operations such as drilling, tapping, milling, and contouring. This versatility enables manufacturers to complete multiple machining processes in a single setup, which is not always possible with traditional milling machines. By consolidating multiple operations into one machine, Weish’s gantry milling solutions streamline production workflows, enhance productivity, and lower overall operational costs.

Drawbacks to Consider with Gantry Milling Machines

Despite their many advantages, gantry milling machines have some drawbacks that may affect cost-effectiveness for certain applications. The initial cost and space requirements of gantry machines are typically higher than those of traditional milling machines. Additionally, the complexity of these machines may require specialized training for operators and more frequent maintenance, which could increase operational costs. Therefore, it is essential to evaluate the specific machining needs and project requirements before choosing between gantry and traditional milling machines.

Conclusion: Which Machine is More Cost-Effective for Your Needs?

Determining whether gantry milling machines are more cost-effective than traditional milling machines depends on your specific machining needs and production goals. For manufacturers working with large, complex parts or requiring high levels of precision and efficiency, gantry milling machines, like those offered by Weish, can provide substantial long-term savings and performance benefits. However, for smaller-scale projects or operations with limited space and budget, traditional milling machines may be the more economical choice. Consulting with a reputable CNC machine manufacturer like Weish can help you assess your options and choose the most cost-effective solution for your business.