Introduction to Weish and CNC Machines

Weish, a leading CNC machine manufacturer, is dedicated to providing state-of-the-art CNC machines that cater to a wide range of industrial needs. In today’s manufacturing landscape, achieving high precision is crucial for ensuring quality and meeting stringent industry standards. This article explores whether a CNC machine is necessary for high-precision work and how Weish’s advanced CNC machines fulfill this requirement.

Understanding High-Precision Work

Definition of High-Precision

High-precision work involves manufacturing components with extremely tight tolerances and exact specifications. This level of accuracy is essential in industries such as aerospace, medical devices, automotive, and electronics, where even the smallest deviations can lead to significant issues.

Traditional vs. CNC Machining

Traditional machining methods, such as manual milling and turning, rely heavily on the operator’s skill and experience. While skilled machinists can achieve high precision, the process is time-consuming and prone to human error. In contrast, CNC (Computer Numerical Control) machining automates the process, ensuring consistent and repeatable precision across multiple parts.

Advantages of CNC Machines for High-Precision Work

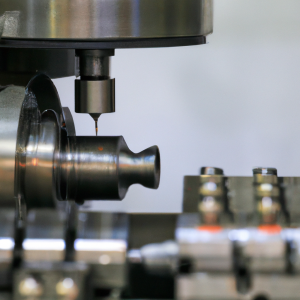

Enhanced Accuracy and Repeatability

CNC machines, like those manufactured by Weish, are programmed to follow exact specifications, eliminating human error. The precision of CNC machines is unparalleled, with tolerances often within microns. This level of accuracy is critical for producing high-precision components consistently.

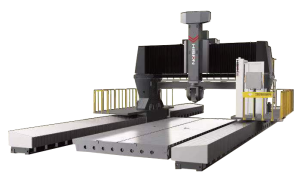

Advanced Multi-Axis Capabilities

Weish CNC machines are equipped with multi-axis capabilities, allowing for the creation of complex geometries and intricate designs. Traditional machines often struggle with such complexity, but CNC machines handle it effortlessly, ensuring high precision in even the most challenging applications.

Automation and Efficiency

CNC machines automate the machining process, significantly increasing efficiency and productivity. Weish’s CNC machines can operate continuously with minimal supervision, reducing the time and cost associated with manual machining. Automation also ensures that each part produced is identical, maintaining high precision throughout production runs.

Key Features of Weish CNC Machines

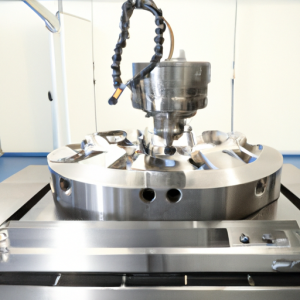

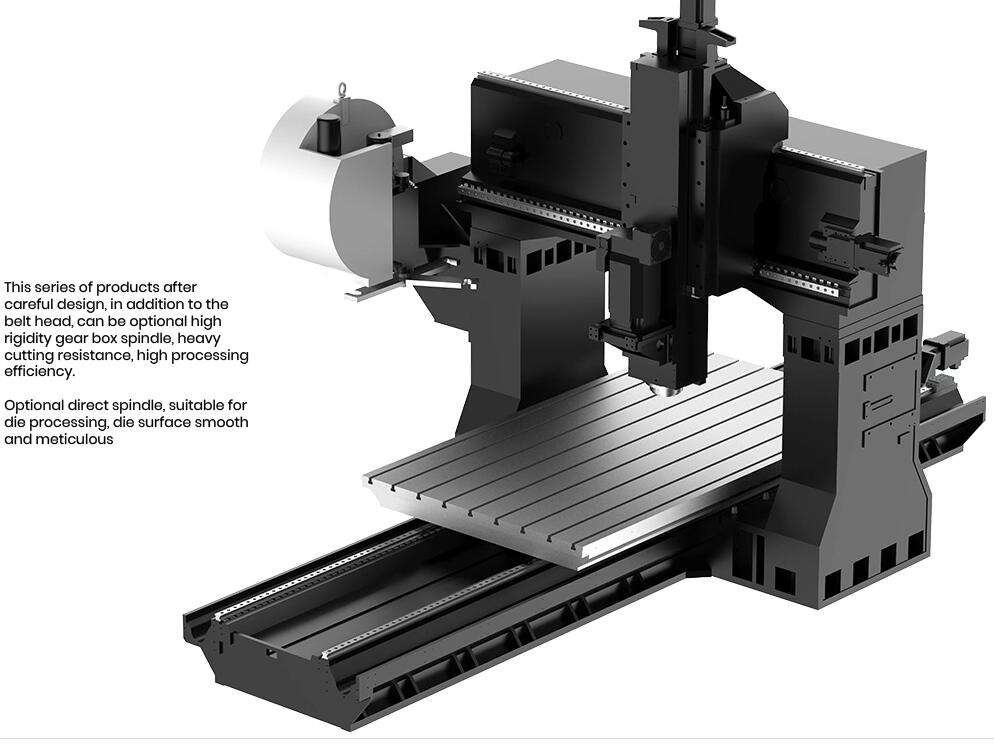

High-Speed Machining

Weish’s CNC machines incorporate high-speed machining technologies that enhance precision and reduce cycle times. High-speed spindles and rapid feed rates enable the machines to achieve finer surface finishes and tighter tolerances.

Advanced Control Systems

Weish utilizes advanced control systems in their CNC machines, providing precise control over the machining process. These systems include real-time feedback and adaptive control features, ensuring optimal performance and accuracy.

Quality Materials and Tooling

The use of high-quality materials and tooling in Weish CNC machines ensures durability and precision. Premium-grade components and cutting tools maintain their integrity and sharpness over extended periods, contributing to consistent high-precision work.

Applications of Weish CNC Machines in High-Precision Work

Aerospace Industry

In the aerospace industry, precision is paramount. Weish CNC machines produce critical components for aircraft and spacecraft, ensuring they meet rigorous safety and performance standards. The ability to machine complex parts with high accuracy makes Weish CNC machines indispensable in this field.

Medical Devices

Medical devices require precision and reliability. Weish CNC machines manufacture components for surgical instruments, implants, and diagnostic equipment, adhering to stringent regulatory requirements. The high precision of Weish machines ensures the safety and effectiveness of medical products.

Automotive Industry

The automotive industry benefits from the high precision of Weish CNC machines in producing engine components, transmission parts, and custom interior elements. The accuracy and repeatability of CNC machining ensure the performance and reliability of automotive parts.

Conclusion: The Necessity of CNC Machines for High-Precision Work

In conclusion, CNC machines are essential for achieving high-precision work. The automation, accuracy, and advanced capabilities of CNC machines, like those offered by Weish, make them indispensable in modern manufacturing. By leveraging the latest technologies, Weish ensures that their CNC machines meet the demands of industries requiring exacting standards and high precision.