What is a CNC machine?

CNC machine is a computer numerically controlled machine tool used to make precision parts. It is operated by a computer program with commands to move parts or cutting tools in three-dimensional space. The machines are most commonly used to make small series of precision parts and can work with a variety of materials such as metals, plastics, composites, and wood.

How do CNC machine manufacturer produce CNC machine?

CNC machine manufacturer typically produce CNC machine by assembling various components, including motors, controllers, and cutting tools. Then connect the components together using cables and electrical connectors, and program the machine using software programs. Then test and calibrate the machine to ensure its normal operation.

The range of technologies they use can be divided into three categories.

The first stage is to create a 3D model. CNC machine manufacturers use complex CAD software to design the three-dimensional structure of machine tools, including various components. The CAD model includes detailed information about the machine structure, including the materials to be used and the dimensions of all parts.

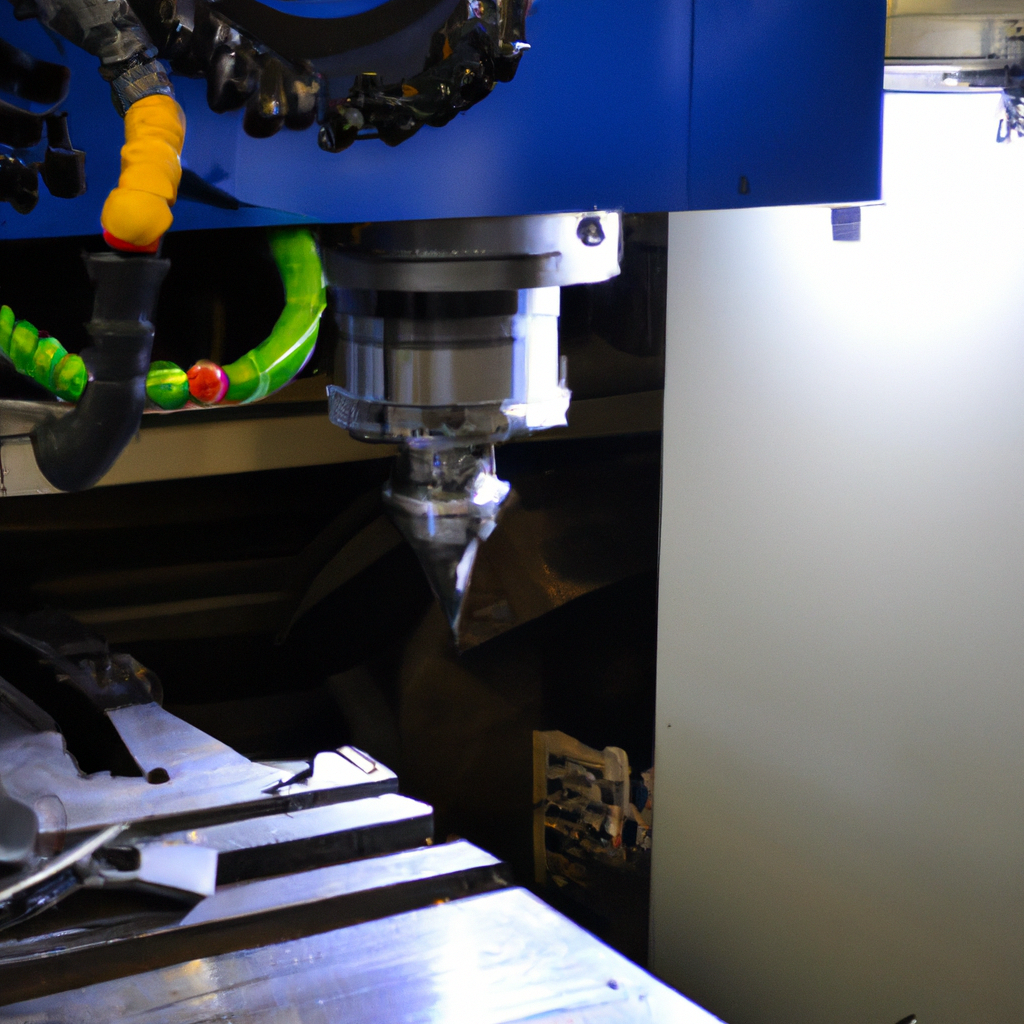

The next step is to cut and grind the various components of the machine. This is accomplished using a series of machines, such as CNC milling machines, laser cutting machines, and even manual tools such as saws and drilling machines. These tools cut and shape components according to the precise specifications of the 3D model.

The final step is assembly. Place the assembled components and hardware together based on the 3D model. After assembly, test the machine to ensure its correct operation and prepare for shipment.

How many types of CNC machine are there?

There are various types of CNC machine, which can be divided into the following categories:

Lathe CNC machine: A lathe is used to manufacture cylindrical or conical shapes by removing materials from rotating billets. They are usually used for machining high-precision small parts, such as screws and nuts.

Drilling and boring CNC machines: These machines are used for drilling, chamfering, and other machining operations on workpieces. They come in various sizes, and the smallest can only handle objects with a diameter of only a few millimeters.

CNC milling machine: milling machine are used to cut and shape flat materials such as metal, wood, and plastic. Their range ranges from basic models of manual feeding to complex computer numerical control (CNC) machines that can generate complex shapes in various materials.

Laser cutting CNC machine: These machines use laser beams to cut workpieces. Laser can generate highly accurate cutting lines with minimal material removal.

Plasma cutting CNC machine: Plasma cutting machine uses plasma jet to cut metal. They are usually used for cutting thicker materials than laser cutting machines, and can also be used for welding together with various filler materials.

Router machine, Trimmers, and Shapers CNC Machine: These machines are used for cutting contours, hollow objects, shaping, and trimming excess materials.

CNC machine for water jet cutting: These machines use high-pressure water flow or abrasive to cut materials. They are usually used to cut complex shapes, otherwise it is difficult to achieve.

What products can CNC machine produce?

CNC machine is computer-controlled machines used to produce precision components from various materials such as metal, plastic, wood, and composite materials. They can be used to produce various products, from medical parts to machine parts, and then to consumer goods.

In the automotive industry, CNC machine is used to produce all products from engine components (such as crankshafts and engine blocks) to automotive internal components (such as dashboard components and interiors).

In the aerospace field, CNC machine is used to manufacture aircraft components, such as the fuselage, wings, and tail. They can also produce engine components such as turbine discs and blades, as well as complex flight control systems.

In the medical field, CNC machine is used to manufacture medical implants, such as prosthetics and orthopedic implants. Some parts, such as the hip joint and femoral head used for reconstruction surgery, are processed using CNC. The manufacturing of medical implants is particularly challenging as they require processing to extremely precise specifications.

CNC machine is also used for manufacturing products in the consumer and commercial sectors. From golf clubs to furniture, musical instruments, firearms, and tools, all items are produced using CNC machine. CNC machine can quickly produce products with complex geometric shapes and designs in small batches, making them very suitable for customized manufacturing and small to medium-sized batch production.

In addition to a wide range of products used for manufacturing, CNC machine can also produce complex Machine element, such as robot parts, gears and other Machine element. The complexity of these projects and the required accuracy make them an ideal choice for CNC machining.

Design Prototype of CNC Machine

The CNC machine prototype design would include a base frame made of sturdy material like aluminum or steel, and a main frame that attaches to the base with hydraulic supports. The main frame would hold three separate linear axes for moving the machine around and precise movement of the tool. Each axis would also feature a motor and lead screw for precise motion. The prototype design would also include a spindle to hold the cutting tool, an electronic controller to program the machine movements, and a cutting head to carry out the desired motion. The entire machine would come together in a durable and reliable design that is easy to use and operate.

CNC machine manufacturer need to have the following production equipment

CNC machine manufacturer require various production equipment in order to provide efficient and high-quality machines. This includes a lathe, milling machine, CNC machine, grinding machine, drills, band saws, shears, presses, and more. Additionally, CNC machines need other specialized equipment, such as abrasive products, tooling systems, and other fixtures. For more complex machining, CNC machine manufacturers often need to use a balancing machine to check the accuracy of their products, or a laser marking system to design and customize machines specific to customer desires. As computer-aided design (CAD) software becomes more popular, CNC machine manufacturer require CNC controllers, as well as computer numerical control (CNC) programming software, and CNC hardware to facilitate production. Finally, CNC machine manufacturer need post-processing machines such as cutters and deburring machines to ensure a smooth finish.

Maintenance and Precautions for CNC Machine

CNC machine require regular maintenance to ensure their normal operation.

Firstly, it is important to regularly lubricate and cool the parts of the CNC system. Follow the instructions of the CNC machine manufacturer for operation. In addition, it is also important to check whether all components such as bearings, belts, pins, screws, and nuts are properly fixed. Small wear and tear items should also be replaced regularly.

Secondly, it is important to regularly check all electrical connections. Ensure that all wiring is organized and properly fixed to avoid any loose connections that may cause short circuits or other electrical damage.

Thirdly, regularly clean the CNC system. This includes cleaning the cutting table, belts, and electrical contacts. Use compressed air or light solvent to remove any debris that may be collected near the cutting table.

Fourthly, any non-conforming parts should be immediately removed and replaced. This includes any parts that are worn, cracked, dented, or otherwise damaged.

Finally, it is important to use the correct tools when operating or repairing CNC machine. This includes using the correct drill bit, tap, and wrench. In addition, ensure sufficient lighting so that all components are clearly visible.

It is important to ensure that your CNC machine is regularly maintained and all safety precautions are taken, as this will help extend the service life of the CNC system. In addition, it is also necessary to keep maintenance and repair records of CNC machine, as this will help ensure that all replacement parts are available at all times and any issues are resolved in a timely manner.

Service and Quality System of CNC Machine Manufacturer

The service and quality system of a CNC machine manufacturer focuses on providing the best customer service experience, delivered with the highest quality available. The system works to ensure that customers receive a reliable product with good accuracy, repeatability, and consistent performance.

CNC Machine manufacturer creates a detailed process plan for each CNC machine, making sure that all components meet the manufacturer’s requirements. Furthermore, the machines are tested and calibrated before being shipped to customers. The manufacturer also provides post-sale service to ensure ongoing customer satisfaction. This includes installation, training, maintenance, and repair services.

Additionally, the manufacturer inspects and certifies each CNC machine to ensure that it meets their quality standards. Finally, the manufacturer documents their quality and service system to maintain customer trust and compliance. This includes monitoring customer feedback, conducting regular audits, and implementing corrective measures when necessary.

What is CNC machine design?

CNC (Computer Numerical Control) machine design is an automated form where operators program equipment or equipment systems to perform a series of tasks, such as cutting, drilling, forming, and assembly, without direct human involvement. CNC design realizes higher precision and accuracy than manual labor, as well as higher productivity and lower possibility of Product defect risk.

CNC machine design includes programming the computer controlled motors of the machine tool to accurately perform manufacturing operations. During the setup process, the operator quantifies the manufacturing process to accurately create CNC programs. Then load the program into the system and send the command to the machine’s axis motor.

CNC systems can be divided into three main components: controllers, machine tools, and tools. The controller is the “brain” of a machine, interpreting CNC programs as a series of machine processes. The machine provides mechanical motion and servo motors controlled by a controller. Tools help with the operation and movement of workpieces. All these components must be properly connected and set up to ensure the normal operation of the CNC system.

Weish CNC MASTER is a professional CNC machine manufacturer concentrating all its resources on developing and building CNC 5 axis gantry milling machine, CNC boring mill,router machine and CNC vertical lathe with C axis. Ever since its early days, Weish CNC has operated with “elitism ” as its business philosophy, focusing upon efficient management of human resources.