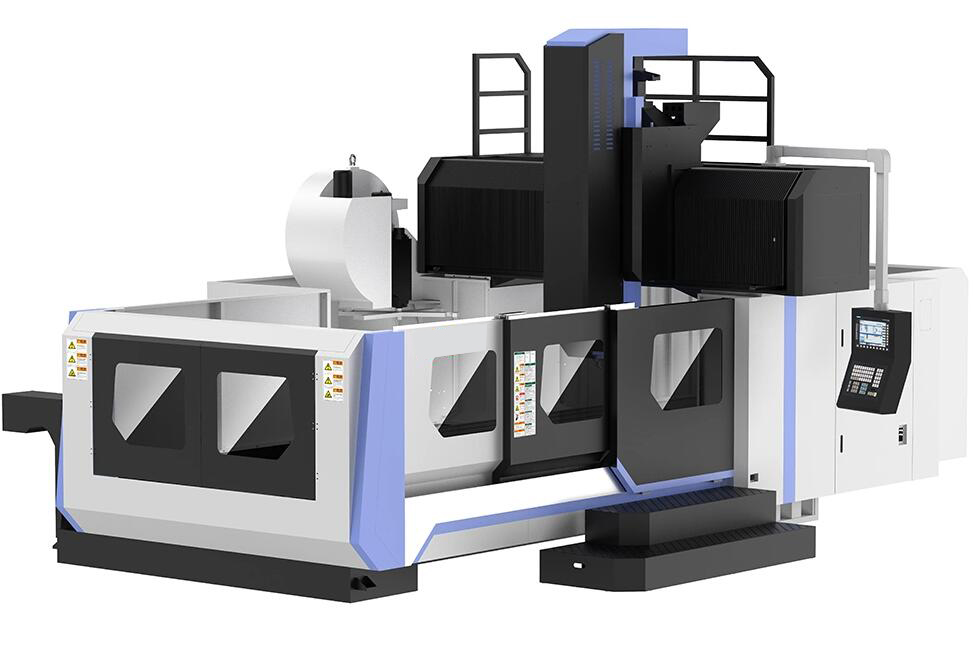

CNC machine centers have revolutionized the manufacturing industry by offering precise and efficient machining capabilities for a wide range of materials. As a leading CNC machine manufacturer, Weish understands the importance of versatility in machining. However, the suitability of CNC machine centers for different materials can depend on several factors, including the machine’s capabilities, the properties of the material, and the specific machining requirements.

What Types of Materials Can Be Machined with CNC Centers?

CNC machine centers are designed to handle a diverse array of materials, making them highly versatile in various industries. Here are some common materials that can be effectively machined using CNC centers:

- Metals: CNC machine centers are highly effective in machining a wide range of metals, including aluminum, steel, titanium, brass, and copper. These machines can achieve high precision and excellent surface finishes, which are crucial in industries such as aerospace, automotive, and medical device manufacturing.

- Plastics: CNC machining is also suitable for various plastic materials, including ABS, PVC, polycarbonate, and acrylic. These materials are often used in prototyping, electronics, and consumer goods due to their lightweight and durable properties.

- Composites: Advanced composites, such as carbon fiber and fiberglass, are increasingly used in high-performance applications. CNC machine centers can be adapted to machine these materials, though special considerations must be made for tool wear and material handling.

- Wood: While less common, CNC machine centers can also be used to machine wood, particularly in applications like furniture manufacturing and custom carpentry. The precision offered by CNC machining allows for intricate designs and repeatable production.

Are There Limitations When Machining Certain Materials?

While CNC machine centers are versatile, there are some limitations and challenges when machining specific materials. Here’s what you need to consider:

- Material Hardness: Extremely hard materials, such as certain ceramics or hardened steels, can pose challenges for CNC machining. Specialized tools and slower cutting speeds may be required to effectively machine these materials without excessive tool wear.

- Brittleness: Brittle materials, such as glass or some ceramics, require careful handling during machining. CNC machine centers can be equipped with diamond-coated tools to handle such materials, but the process must be closely monitored to avoid cracking or chipping.

- Thermal Sensitivity: Some materials are highly sensitive to heat, which can cause warping or other deformations during the machining process. In these cases, CNC machine centers may need to use coolant systems or adjust cutting parameters to manage heat generation.

How Does Weish Ensure CNC Machine Centers Are Optimized for Different Materials?

At Weish, we design our CNC machine centers to be as adaptable as possible, ensuring they can handle a wide range of materials with precision and efficiency. Here’s how we optimize our machines:

What Role Do Tooling and Cutting Strategies Play?

Tooling and cutting strategies are crucial in determining how effectively a CNC machine center can handle different materials:

- Custom Tooling: Weish offers a variety of tool options, including carbide, ceramic, and diamond-coated tools, to match the specific requirements of different materials. This ensures optimal cutting performance and prolongs tool life.

- Adaptive Cutting Strategies: Our CNC machine centers are equipped with advanced software that allows for adaptive cutting strategies. This means the machine can adjust its cutting speed, feed rate, and toolpath dynamically based on the material properties, ensuring optimal performance across a range of materials.

How Do CNC Machine Centers Manage Heat and Chip Evacuation?

Managing heat and chip evacuation is critical when machining materials that are prone to heat sensitivity or clogging:

- Coolant Systems: Weish CNC machine centers come equipped with advanced coolant systems that help manage heat generation during machining. This is particularly important when working with materials that are sensitive to thermal deformation.

- Effective Chip Evacuation: Our machines are designed with efficient chip evacuation systems to prevent clogging and ensure a smooth machining process. This is especially crucial when machining materials like aluminum, which can produce long, continuous chips.

What Are the Benefits of Using Weish CNC Machine Centers for Various Materials?

Choosing a Weish CNC machine center offers several advantages for machining different materials:

- Versatility: Our CNC machine centers are designed to handle a wide range of materials, from metals to composites, making them suitable for diverse applications.

- Precision: Whether you’re machining soft plastics or hard metals, our machines deliver the precision required for high-quality parts.

- Efficiency: Weish CNC machine centers are optimized for efficiency, reducing cycle times and minimizing tool wear, regardless of the material being machined.

Conclusion: Are CNC Machine Centers the Right Choice for Your Material?

CNC machine centers are highly versatile and can handle a wide variety of materials, making them an excellent choice for manufacturers across multiple industries. However, understanding the specific properties of the material and optimizing the machine setup accordingly is essential for achieving the best results. Weish, as a trusted CNC machine manufacturer, provides advanced CNC machine centers designed to meet the challenges of machining different materials with precision and efficiency. Whether you are working with metals, plastics, composites, or other materials, Weish has the solution to meet your machining needs.