Introduction

In the world of precision machining, selecting the right equipment is crucial for achieving optimal results. Two popular machines often compared are the CNC Vertical Lathe and the CNC Boring Mill. This article explores the differences in performance, capabilities, and applications of these machines, focusing on Weish, a leading CNC machine manufacturer.

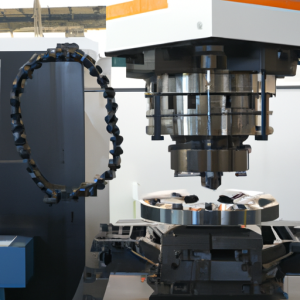

CNC Vertical Lathe: An Overview

What is a CNC Vertical Lathe?

A CNC Vertical Lathe is a type of lathe where the spindle is oriented vertically. This configuration is ideal for handling large, heavy workpieces that require stability during machining. Weish’s CNC Vertical Lathes are known for their precision and reliability, making them a popular choice in various industries.

Key Features of Weish CNC Vertical Lathes

1. High Rigidity and Stability

Weish’s CNC Vertical Lathes are designed with robust structures, ensuring high rigidity and stability during operations. This design minimizes vibrations, leading to superior surface finishes and precise tolerances.

2. Advanced CNC Control Systems

Equipped with the latest CNC control systems, Weish’s Vertical Lathes offer intuitive operation and advanced programming capabilities. These systems enhance productivity by allowing for complex machining tasks to be performed with ease.

3. Versatility in Workpiece Handling

Weish’s CNC Vertical Lathes can handle a wide range of materials, from metals to composites. Their ability to accommodate various workpiece sizes and weights makes them suitable for industries like aerospace, automotive, and heavy machinery.

Advantages of Using Weish CNC Vertical Lathes

- Enhanced Accuracy: The vertical orientation provides better control over the cutting process, leading to higher precision.

- Space Efficiency: Vertical Lathes occupy less floor space compared to horizontal counterparts.

- Ease of Operation: Loading and unloading of workpieces are simplified, reducing operator fatigue and improving workflow efficiency.

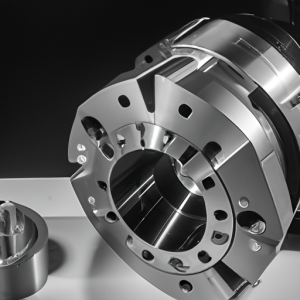

CNC Boring Mill: An Overview

What is a CNC Boring Mill?

A CNC Boring Mill is a machine used for enlarging holes in a precise and controlled manner. It is particularly useful for boring large-diameter holes and is commonly used in industries that require high-precision components. Weish’s CNC Boring Mills are known for their robust construction and advanced features.

Key Features of Weish CNC Boring Mills

1. Precision Boring Capabilities

Weish CNC Boring Mills are engineered for high-precision boring operations. They feature advanced spindle systems and tool holders that ensure minimal deflection and high accuracy.

2. Large Work Envelope

With a large work envelope, Weish CNC Boring Mills can handle oversized workpieces. This capability is essential for industries such as energy, mining, and shipbuilding, where large components are common.

3. Integrated Automation

Weish integrates automation solutions into their CNC Boring Mills, including tool changers and robotic handling systems. These features increase efficiency and reduce downtime.

Advantages of Using Weish CNC Boring Mills

- High Precision: Weish CNC Boring Mills deliver precise and consistent results, making them ideal for critical applications.

- Versatility: They can perform a variety of tasks, including milling, drilling, and tapping, in addition to boring.

- Durability: Built with high-quality materials, these machines are designed for long-term operation and minimal maintenance.

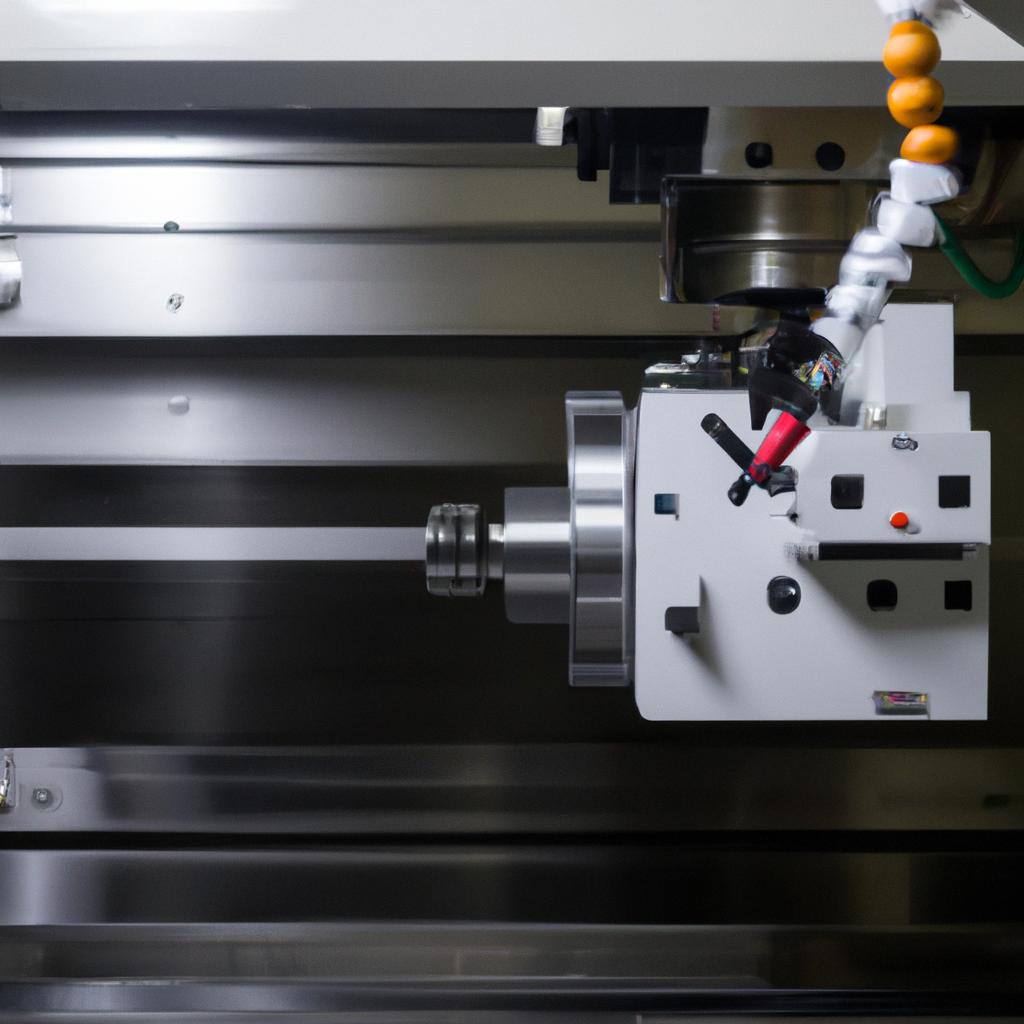

Performance Comparison: CNC Vertical Lathe vs. CNC Boring Mill

Accuracy and Precision

- CNC Vertical Lathe: Offers excellent accuracy in turning operations, especially for large workpieces.

- CNC Boring Mill: Excels in precision boring and enlarging existing holes with minimal deviation.

Workpiece Size and Weight

- CNC Vertical Lathe: Ideal for large, heavy workpieces that require stable support.

- CNC Boring Mill: Suitable for oversized components, particularly where deep boring is necessary.

Versatility and Applications

- CNC Vertical Lathe: Versatile in handling a wide range of materials and shapes, used in automotive, aerospace, and heavy machinery industries.

- CNC Boring Mill: Specializes in boring large holes but also performs milling and drilling operations, commonly used in energy, mining, and shipbuilding industries.

Conclusion

Choosing between a CNC Vertical Lathe and a CNC Boring Mill depends on the specific needs of the application. Weish offers both types of machines, each with unique strengths and capabilities. For high-precision turning operations, the CNC Vertical Lathe is an excellent choice, while the CNC Boring Mill is ideal for precise boring and handling large components. Regardless of the choice, Weish’s commitment to quality and innovation ensures reliable performance and superior results in every machining task.