Why is Safety Important in CNC Boring Machine Operations?

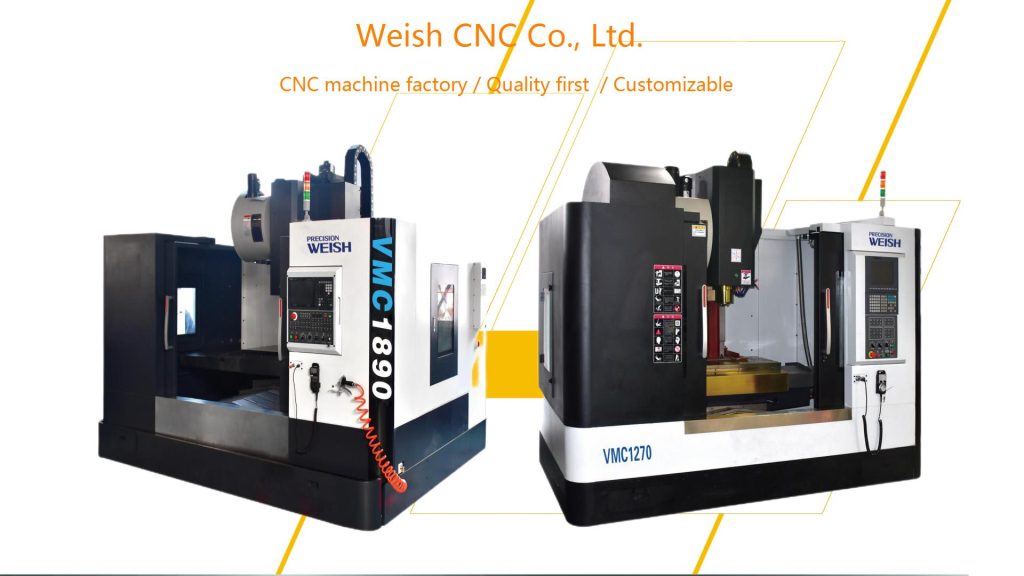

Safety is a critical consideration in CNC boring machine operations due to the high-speed cutting, rotating parts, and precision required in machining processes. CNC boring machines, like those manufactured by Weish, are designed to handle complex machining tasks with minimal manual intervention. However, improper use or lack of safety features can lead to accidents, machine damage, and compromised part quality. Therefore, it is essential to understand and implement the necessary safety features to ensure a safe and productive work environment.

What Safety Features Should You Look for in a CNC Boring Machine?

When selecting a CNC boring machine, it’s vital to consider specific safety features that protect operators and enhance overall machine performance. Key safety features to look for include emergency stop buttons, interlock guards, and advanced sensor systems. Weish, a trusted CNC machine manufacturer, integrates these features into its machines to provide comprehensive safety for operators and ensure reliable operation. Below are some of the primary safety features you should evaluate:

Emergency Stop Button and Interlock System

One of the most essential safety features in a CNC boring machine is the emergency stop button. This button allows operators to immediately halt the machine in case of any abnormalities, preventing potential accidents. The interlock system, on the other hand, prevents the machine from operating when the safety doors or covers are open, ensuring that the machine does not start unless all safety measures are in place. Weish’s CNC boring machines are equipped with both emergency stop buttons and interlock systems, ensuring maximum protection during operation.

Machine Guarding and Enclosures

Machine guarding is another critical safety feature designed to protect operators from hazards such as flying chips, coolant splash, or direct contact with moving parts. Weish’s CNC boring machines come with robust guarding and full enclosures that shield operators from these potential dangers. These guards are typically made of impact-resistant materials and include viewing windows that allow operators to monitor the machining process without compromising safety.

Advanced Sensor Systems and Overload Protection

Weish CNC boring machines are equipped with advanced sensor systems that detect irregularities in machine operation, such as vibration, overheating, or tool breakage. These sensors can automatically shut down the machine or alert operators in case of any issues, minimizing the risk of damage or accidents. Additionally, overload protection systems prevent the machine from exceeding its operational limits, protecting both the machine and the workpiece from harm.

Automated Coolant Systems and Chip Management

Effective coolant and chip management systems are essential for maintaining a safe and clean work environment. Weish’s CNC boring machines feature automated coolant systems that keep the cutting tools and workpieces cool, reducing the risk of heat-related accidents. Additionally, built-in chip management systems remove chips from the cutting area, ensuring that they do not interfere with machine operation or pose a safety hazard to operators.

Ergonomic Design and Operator-Friendly Interface

An ergonomic design and user-friendly interface are also vital safety considerations in CNC boring machines. Weish’s machines are designed with operator comfort and convenience in mind, featuring easy-to-reach controls, adjustable workstations, and intuitive interfaces that reduce operator fatigue and the likelihood of errors. This ergonomic approach not only enhances operator safety but also boosts productivity and operational efficiency.

Final Thoughts on Safety Features in CNC Boring Machines

In conclusion, ensuring safety in CNC boring machine operations requires careful consideration of various features, such as emergency stop buttons, interlock systems, machine guarding, and advanced sensor technology. Weish, a reputable CNC machine manufacturer, integrates these safety features into its machines to provide a safe and reliable solution for machining operations. By prioritizing safety, companies can protect their workforce, minimize downtime, and optimize machine performance. For more information on Weish’s CNC boring machines and their safety features, reach out to our team of experts today.