FM, a leading CNC machining parts manufacturer, is committed to providing top-tier precision parts through advanced manufacturing technologies. One of the cornerstones of modern manufacturing is the CNC machine. This article offers a detailed overview of what a CNC machine is, how it works, its benefits, and its applications.

Introduction to CNC Machines

Definition and Overview

What is a CNC Machine?

CNC stands for Computer Numerical Control. A CNC machine is a sophisticated device that automates the control of machining tools through the use of computers executing pre-programmed sequences of machine control commands. This automation results in highly precise and repeatable manufacturing processes.

Types of CNC Machines

There are various types of CNC machines, including:

- CNC Mills

- CNC Lathes

- CNC Routers

- CNC Plasma Cutters

- CNC Laser Cutters

- CNC Electric Discharge Machines (EDM)

How CNC Machines Work

Basic Components

CNC machines consist of several key components:

- Controller: The brain of the CNC machine, which interprets the G-code instructions.

- Drive/Motors: Responsible for movement along the machine’s axes.

- Machine Bed: Provides stability and support for the workpiece.

- Cutting Tools: Execute the machining operations.

The CNC Process

- Design Phase: The part is designed using CAD (Computer-Aided Design) software.

- Programming Phase: The design is converted into a G-code using CAM (Computer-Aided Manufacturing) software.

- Setup Phase: The workpiece and tools are set up in the CNC machine.

- Machining Phase: The CNC machine executes the programmed instructions to create the part.

Benefits of CNC Machines

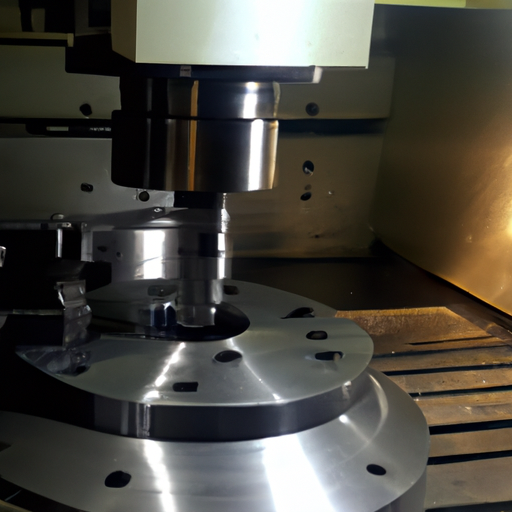

Precision and Accuracy

High Tolerances

CNC machines can achieve extremely tight tolerances, often within microns. This precision ensures that parts meet exact specifications and quality standards.

Consistent Quality

The repeatability of CNC machines guarantees that each part produced is identical, reducing variability and enhancing product reliability.

Efficiency and Productivity

Faster Production

CNC machines can operate continuously and at high speeds, significantly reducing production times compared to manual machining.

Automation

The automation of machining processes reduces the need for human intervention, lowering labor costs and minimizing the risk of human error.

Versatility

Complex Geometries

CNC machines can handle complex designs and intricate geometries that would be challenging or impossible with manual machining.

Multi-Functionality

Many CNC machines are capable of performing multiple operations, such as milling, drilling, and turning, in a single setup.

Applications of CNC Machines

Aerospace

High-Precision Components

The aerospace industry relies on CNC machines to produce high-precision components that meet stringent safety and performance standards.

Automotive

Engine Parts and Body Components

CNC machines are used extensively in the automotive industry to manufacture engine parts, transmission components, and body parts with high precision and consistency.

Medical Devices

Surgical Instruments and Implants

The medical industry utilizes CNC machines to produce surgical instruments and implants that require exacting precision and biocompatibility.

Electronics

Circuit Boards and Housings

In electronics manufacturing, CNC machines are used to create circuit boards, housings, and other components with intricate designs and tight tolerances.

Key Features of FM’s CNC Machines

Advanced Technology

State-of-the-Art Controllers

FM’s CNC machines are equipped with the latest controllers, ensuring precise and efficient execution of machining operations.

High-Speed Spindles

Our CNC machines feature high-speed spindles that enable rapid material removal and superior surface finishes.

Customization and Flexibility

Tailored Solutions

FM offers customized CNC machining solutions tailored to meet the specific needs of our clients, ensuring optimal performance and efficiency.

Wide Range of Capabilities

Our CNC machines can handle a diverse array of materials and machining operations, providing versatility and flexibility for various applications.

Quality Assurance

Rigorous Testing

Each CNC machine undergoes rigorous testing to ensure it meets FM’s high standards for performance, reliability, and precision.

Certification and Compliance

FM’s CNC machines are compliant with industry standards and certifications, guaranteeing quality and safety in all our manufacturing processes.

Conclusion

CNC machines are a pivotal technology in modern manufacturing, offering unparalleled precision, efficiency, and versatility. As a leading CNC machining parts manufacturer, FM leverages advanced CNC machinery to deliver high-quality, precision-engineered parts across various industries. Whether you need components for aerospace, automotive, medical, or electronics applications, FM’s state-of-the-art CNC machines and expert team are here to meet your manufacturing needs with excellence and reliability.