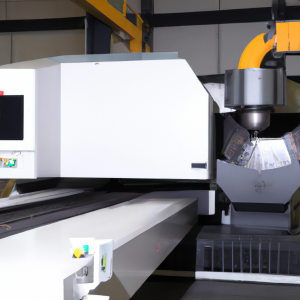

The DHX Gantry Machining Center represents a significant advancement in CNC technology, offering unmatched precision, speed, and versatility for various machining tasks. As a premier CNC machine manufacturer, Weish is proud to introduce this state-of-the-art machining center designed to streamline workflow and enhance productivity in manufacturing environments. The DHX Gantry Machining Center is ideal for large, complex parts that require high accuracy and consistency.

What Makes the DHX Gantry Machining Center Stand Out?

The DHX Gantry Machining Center is engineered to meet the demands of modern manufacturing with its advanced features and robust construction. Here’s what sets it apart:

- Large Work Envelope: The DHX Gantry features an expansive work envelope, allowing it to handle large components with ease. This makes it perfect for industries such as aerospace, automotive, and heavy equipment manufacturing.

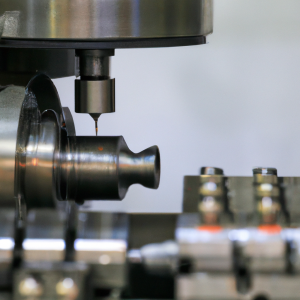

- High Precision: Equipped with precision linear guides and ball screws, the DHX Gantry ensures exceptional accuracy, even when machining complex geometries. This high level of precision translates into consistent part quality and reduced need for post-processing.

- Stability and Rigidity: The gantry structure provides superior stability, minimizing vibrations and ensuring consistent cutting performance. This rigidity is crucial for maintaining precision, especially during heavy-duty machining operations.

How Does the DHX Gantry Machining Center Enhance Workflow Efficiency?

Efficiency is a critical factor in any manufacturing process, and the DHX Gantry Machining Center is designed with features that streamline operations and reduce cycle times. Here’s how it enhances workflow:

- Simultaneous 5-Axis Machining: The DHX Gantry’s capability to perform simultaneous 5-axis machining enables the production of complex parts in a single setup, drastically reducing the time and labor required for multi-step processes.

- Integrated Automation: With the option to integrate automation systems such as robotic loaders and unloaders, the DHX Gantry can operate continuously with minimal human intervention, increasing throughput and reducing downtime.

- Advanced Control Systems: The DHX Gantry is equipped with cutting-edge CNC controls that offer real-time monitoring and adaptive control features. This ensures optimal cutting conditions are maintained throughout the machining process, enhancing both speed and accuracy.

What Applications Are Best Suited for the DHX Gantry Machining Center?

The versatility of the DHX Gantry Machining Center makes it suitable for a wide range of applications across various industries. Some of the key applications include:

- Aerospace Components: The precision and large work envelope make the DHX Gantry ideal for machining large, complex aerospace parts such as fuselage components, wing structures, and engine parts.

- Automotive Parts: From engine blocks to transmission cases, the DHX Gantry can handle the rigorous demands of automotive part production, ensuring high precision and repeatability.

- Mold and Die Manufacturing: The ability to machine intricate details and maintain tight tolerances makes the DHX Gantry perfect for producing high-quality molds and dies used in plastic injection molding and metal stamping.

How Does Weish Ensure Quality and Performance in the DHX Gantry Machining Center?

At Weish, quality and performance are at the core of our manufacturing philosophy. The DHX Gantry Machining Center is a testament to our commitment to excellence. Here’s how we ensure every machine meets the highest standards:

What Testing and Calibration Processes Are Used?

Before a DHX Gantry Machining Center is delivered to a customer, it undergoes rigorous testing and calibration:

- Precision Testing: Each machine is tested for accuracy using advanced measurement tools to ensure it meets the exacting tolerances required by our clients.

- Dynamic Performance Testing: We simulate real-world machining conditions to evaluate the machine’s performance under load, ensuring it can handle the demands of high-speed, high-precision machining.

- Continuous Improvement: Feedback from customers is continuously integrated into our design and manufacturing processes, ensuring that each generation of the DHX Gantry incorporates the latest advancements in CNC technology.

Conclusion: Why Choose Weish’s DHX Gantry Machining Center?

The DHX Gantry Machining Center by Weish is a game-changer for manufacturers looking to enhance their workflow efficiency and produce high-quality parts consistently. With its large work envelope, advanced machining capabilities, and robust construction, it is designed to meet the challenges of modern manufacturing head-on. Trust Weish, a leading CNC machine manufacturer, to deliver the technology you need to stay competitive in today’s demanding market. Whether your focus is on precision, speed, or versatility, the DHX Gantry Machining Center offers the solutions you need to succeed.