How Can Weish’s Simulation Techniques Enhance CNC Machine Performance?

Weish, a top-tier CNC machine manufacturer, utilizes cutting-edge simulation techniques to optimize the performance and precision of its CNC machines. These simulations enable engineers and operators to digitally model the machining process, allowing them to predict outcomes, detect potential issues, and refine tool paths before actual production begins. By simulating the machining process, Weish can identify opportunities to improve efficiency, such as reducing cycle times, minimizing tool wear, and enhancing cutting accuracy. Simulation techniques also provide insights into material behavior, ensuring that machines are programmed to deliver optimal results with minimal waste. With these tools, Weish machines offer the highest levels of reliability and performance, boosting productivity while lowering operational risks. The ability to test various machining strategies beforehand translates into fewer errors and better resource management during production.

What Are the Core Features of Weish CNC Machine Simulation for Optimization?

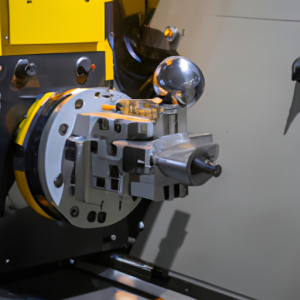

Weish CNC machines are equipped with robust simulation tools integrated directly into the machine control systems. The core features include real-time process visualization, allowing operators to monitor virtual tool paths and material removal before starting production. This visualization prevents potential collisions, excessive tool wear, or defects, ensuring a smooth operation. Weish also provides multi-axis simulation capabilities, critical for optimizing complex geometries in industries like aerospace and automotive, where precision is paramount. The automatic toolpath correction function adjusts machining parameters dynamically based on the simulation feedback, reducing the need for manual intervention. Additionally, Weish’s simulation software ensures optimal tool utilization by predicting wear patterns and suggesting the best tool choices, prolonging tool life and reducing downtime for replacements. These features, combined with Weish’s user-friendly interface, allow operators to quickly simulate and optimize their machining processes, resulting in faster production cycles and higher-quality parts.

How Does Weish Use Simulation to Reduce Production Costs?

Weish uses simulation techniques to significantly lower production costs by improving resource efficiency and reducing waste. The simulation tools embedded in Weish’s CNC machines allow manufacturers to test various machining strategies virtually, identifying the most efficient tool paths and cutting conditions for each project. This virtual testing eliminates costly trial-and-error approaches on actual materials, minimizing scrap and improving the first-pass success rate. By predicting tool wear and scheduling timely maintenance, Weish’s simulations also help in reducing machine downtime and extending tool life, further lowering operational expenses. Additionally, these simulations optimize energy consumption by fine-tuning the CNC processes, resulting in lower energy costs. By incorporating simulation into their CNC machines, Weish enables manufacturers to achieve higher productivity at reduced operational costs without sacrificing part quality.

What Are the Long-Term Benefits of Weish’s CNC Simulation Techniques?

The long-term benefits of Weish’s CNC simulation techniques go beyond immediate production improvements. By continuously optimizing machining processes through simulation, manufacturers can scale production more effectively, handle more complex jobs, and ensure consistent part quality over time. Simulation allows for the proactive maintenance of machines by identifying wear patterns and performance bottlenecks before they result in breakdowns, leading to a longer machine lifespan and fewer disruptions in production. Furthermore, Weish’s ability to simulate cutting-edge technologies, such as 5-axis milling, ensures that manufacturers can stay ahead of industry trends and meet the demands of increasingly intricate part designs. The ability to fine-tune machine performance with minimal risk positions Weish CNC machines as future-proof solutions for high-performance manufacturing environments.