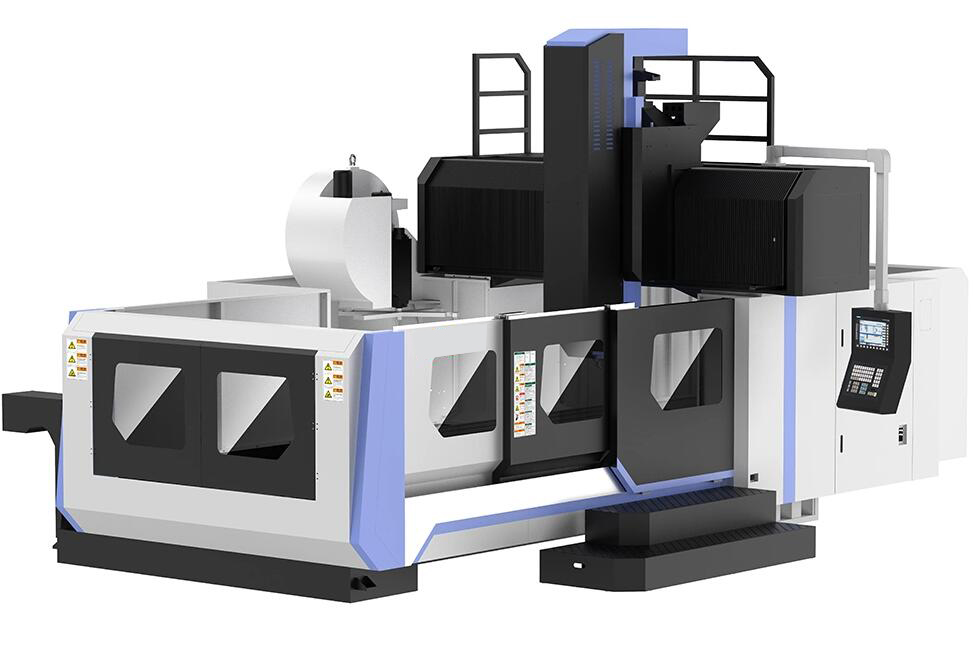

Weish, a leading CNC machine manufacturer, is committed to advancing manufacturing technologies to support innovative product designs. In modern manufacturing, CNC (Computer Numerical Control) machines play a critical role in shaping the design and production of components. This article explores how CNC machines impact product design and how Weish’s cutting-edge machines facilitate innovative and efficient design processes.

Influence of CNC Machines on Product Design

Flexibility in Design

CNC machines provide unparalleled flexibility in product design. Traditional machining methods often impose limitations on the complexity and intricacy of designs due to manual constraints. Weish’s CNC machines, however, allow designers to create complex geometries and intricate features that were previously unattainable. This flexibility enables the production of highly customized and innovative products.

Precision and Consistency

One of the significant advantages of CNC machines is their ability to produce parts with high precision and consistency. Weish CNC machines are programmed to follow exact specifications, ensuring that each component is manufactured to the same precise standards. This consistency is crucial in industries where even minor deviations can affect product performance and safety.

Rapid Prototyping and Iteration

CNC machines significantly accelerate the prototyping and iteration process. Designers can quickly produce prototypes, test them, and make necessary adjustments without extensive delays. Weish’s CNC machines support rapid prototyping, enabling faster development cycles and reducing the time to market for new products. This capability is particularly beneficial for industries that require frequent updates and refinements to their designs.

Key Features of Weish CNC Machines that Enhance Product Design

Advanced CAD/CAM Integration

Weish CNC machines seamlessly integrate with advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This integration streamlines the transition from digital design to physical production. Designers can create detailed models and simulations, which are then directly translated into machining instructions. This process ensures accuracy and reduces the risk of errors during production.

Multi-Axis Machining Capabilities

Weish CNC machines are equipped with multi-axis machining capabilities, allowing for the production of complex and multi-faceted designs. Traditional 3-axis machines are limited to linear movements, whereas multi-axis machines can move the cutting tool along multiple axes simultaneously. This capability is essential for creating intricate components with undercuts, cavities, and other complex features.

High-Speed Machining

High-speed machining is another feature of Weish CNC machines that positively impacts product design. The ability to operate at higher spindle speeds and feed rates reduces machining time and enhances surface finish quality. This capability allows designers to experiment with various materials and finishes, broadening the scope of possible design outcomes.

Applications of CNC Machines in Various Industries

Aerospace

In the aerospace industry, the ability to design and manufacture complex, lightweight, and durable components is crucial. Weish CNC machines enable the production of intricate parts that meet stringent aerospace standards. The precision and reliability of these machines ensure the safety and performance of aerospace components.

Medical Devices

Medical device manufacturing requires high precision and strict adherence to regulatory standards. Weish CNC machines produce surgical instruments, implants, and diagnostic equipment with the necessary precision and consistency. The flexibility in design provided by CNC machining allows for the development of innovative medical solutions tailored to specific patient needs.

Automotive

The automotive industry benefits from the design flexibility and precision offered by CNC machines. Weish CNC machines produce engine components, transmission parts, and custom interior elements that enhance vehicle performance and aesthetics. The ability to rapidly prototype and iterate designs ensures that automotive manufacturers can quickly adapt to changing market demands.

Conclusion: The Impact of CNC Machines on Product Design

CNC machines profoundly impact product design by offering flexibility, precision, and efficiency. Weish’s advanced CNC machines facilitate innovative design processes, enabling the creation of complex and high-quality components across various industries. By integrating cutting-edge technologies and supporting rapid prototyping, Weish ensures that designers can bring their visions to life with unparalleled accuracy and speed.

Tags: CNC Machine manufacturer,Gantry Milling Machine,Double Column Lathe,Milling & Turning Vertical Lathe,Single Column Lathe