In today’s rapidly evolving manufacturing landscape, choosing the right production method is crucial for achieving optimal results. Two popular techniques are CNC machining and 3D printing, each offering unique advantages and limitations. In this article, we will compare CNC machines and 3D printing to help you determine which suits your manufacturing needs best. Weish CNC, a leading CNC machine manufacturer, provides insights into these technologies based on extensive industry experience.

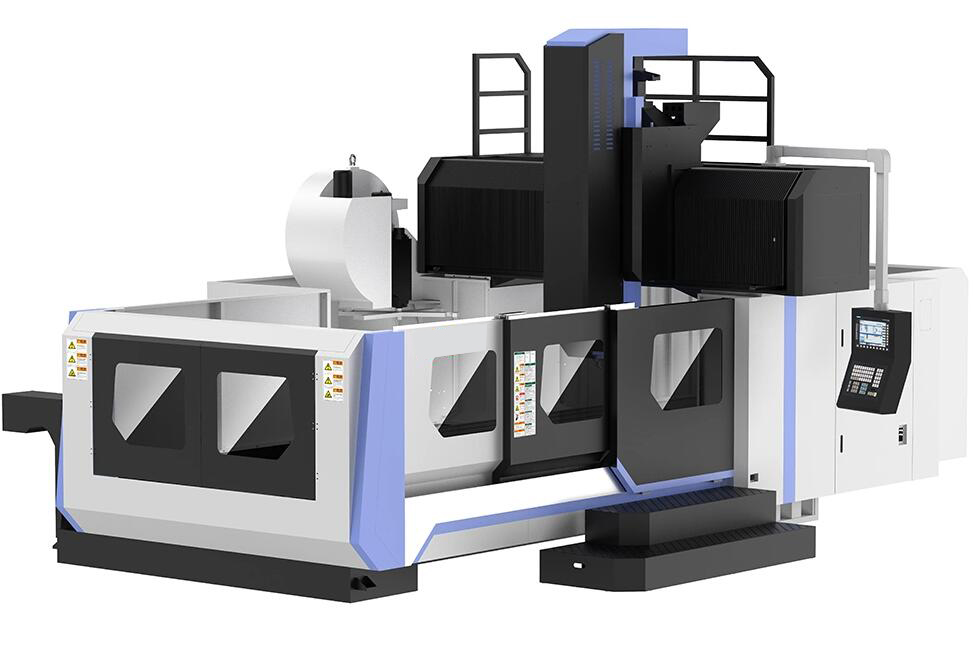

Understanding CNC Machining

What is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses pre-programmed computer software to control the movement of factory tools and machinery. This technique is widely used for producing precise and high-quality parts from various materials, including metals and plastics.

Pros of CNC Machining

Precision and Accuracy

CNC machining is renowned for its high precision and accuracy. Weish CNC’s advanced machines can produce parts with tight tolerances, making them ideal for applications where exact dimensions are critical.

Material Versatility

CNC machines can handle a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics. This versatility allows manufacturers to select the best material for their specific needs.

High Production Speed

For medium to high volume production, CNC machining offers fast production speeds. Once the setup is complete, the machines can produce parts quickly and efficiently.

Cons of CNC Machining

Higher Initial Setup Cost

CNC machining requires significant upfront investment in machinery and tooling. However, the cost performance improves with larger production runs.

Complexity Limitations

While CNC machining can produce complex parts, there are limitations when it comes to intricate internal geometries and fine details that 3D printing can easily achieve.

Understanding 3D Printing

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering material based on digital models. This technology is highly versatile and can produce parts with complex geometries that would be difficult to achieve with traditional manufacturing methods.

Pros of 3D Printing

Design Flexibility

3D printing excels at creating complex shapes and intricate designs. It allows for rapid prototyping and iterative design processes, making it a valuable tool for R&D and innovation.

Low Initial Setup Cost

Compared to CNC machining, 3D printing has a lower initial setup cost, making it accessible for small-scale production and prototyping.

Material Efficiency

3D printing is an additive process, meaning it only uses the material necessary to create the part. This results in minimal waste, contributing to cost savings and sustainability.

Cons of 3D Printing

Limited Material Choices

While 3D printing materials are expanding, they are still limited compared to the variety available for CNC machining. Metals, in particular, are more challenging and expensive to print.

Lower Strength and Durability

Parts produced by 3D printing generally have lower strength and durability compared to those made by CNC machining, especially for load-bearing applications.

Choosing Between CNC Machining and 3D Printing

Factors to Consider

When deciding between CNC machining and 3D printing, consider the following factors:

- Volume: For high-volume production, CNC machining offers better cost performance. For low-volume and prototyping, 3D printing is often more economical.

- Material: Choose CNC machining for metal parts or when a wider variety of materials is needed. 3D printing is suitable for plastic parts and complex designs.

- Lead Time: 3D printing offers shorter lead times for prototypes, while CNC machining provides faster production speeds for large batches.

- Complexity: If your design includes intricate details and complex geometries, 3D printing is likely the better option.

Applications and Industries

CNC Machining Applications

CNC machining is widely used in industries such as automotive, aerospace, and medical device manufacturing. Weish CNC provides OEM/ODM services, ensuring high-quality and precise parts for various applications.

3D Printing Applications

3D printing is popular in industries like consumer electronics, jewelry, and dental prosthetics, where design complexity and rapid prototyping are essential. It is also used for creating custom parts and small-batch productions.

Conclusion

Both CNC machining and 3D printing have their own set of advantages and limitations. Weish CNC, as a trusted CNC machine manufacturer, excels in delivering top-quality parts for various industries. Understanding your specific manufacturing needs, including volume, material, lead time, and complexity, will help you choose the right method. Whether you are looking for a reliable supplier, a distributor, or a partner for your R&D projects, Weish CNC provides the expertise and performance you need to succeed in the competitive market, especially in China.

Tags: CNC Machine manufacturer,CNC Boring Mills,CNC Machine Center,CNC Vertical Lathe,5 Axis Milling Head A/C,Floor Type Boring,Planner Type Boring,Horizontal Boring Machine,Gantry Milling Machine,Double Column Lathe,Milling & Turning Vertical Lathe,Single Column Lathe