CNC Router Machine, also known as CNC engraving machine, is a precision machining equipment in modern manufacturing industry. It is mainly used for precise carving and cutting of various materials, such as wood, plastic, glass, etc.

Its manufacturing and use are widely applied in multiple fields. For example, it can produce customized furniture in the furniture manufacturing industry, accurately cutting and carving based on customer provided drawings or samples. At the same time, it is also used for cutting and carving materials such as stone and glass in the construction and decoration industry.

When selecting and using, some key factors must be considered. Firstly, accuracy and speed are the main factors affecting machine performance. Precision determines the accuracy of cutting and carving, while speed reflects the production efficiency of the machine. Secondly, the durability and reliability of the machine are also very important. If the machine frequently malfunctions, it will affect production efficiency and increase maintenance costs. Finally, the price of the machine is also a factor to consider. The price may vary depending on different performance and application requirements.

CNC Router Machine by interpreting CAD or computer-aided manufacturing (CAM) files. These files contain descriptions of machine motion and tool paths. The controller of the machine uses this data to accurately pass the cutting tool through the material, removing the material as needed to form the desired shape or pattern.

Where can it be used specifically?

Woodworking: CNC routers can carve, shape, and carve wood to make furniture, cabinets, logos, and decorative items.

Metal processing: In metal processing, CNC routers are used to cut and shape materials such as aluminum, brass, and steel for various applications, including building components and metal artworks.

Plastic manufacturing: CNC routers are used for cutting and forming plastic materials, for manufacturing prototypes, molds, and custom parts.

Foam cutting: CNC router is used for precise cutting in foam materials, usually for packaging, thermal insulation or theatrical props.

Stone and glass processing: Some CNC routers are designed for cutting and carving hard materials such as stone and glass, which can create complex designs and artistic works.

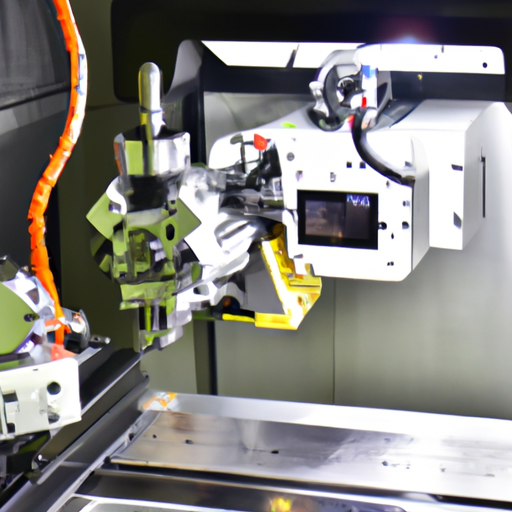

A complete engraving machine consists of the following components:

Workbench: Place and fix the surface of the processed material.

Knife head: A component that fixes a cutting tool (drill bit) and moves it on multiple axes.

Drill bit: A cutting tool used to remove material from a workpiece.

Spindle: An electric motor that rotates a drill bit at high speed for cutting, engraving, or engraving.

Linear guide rail: a precision component that enables the cutting head to move smoothly and accurately along the X, Y, and Z axes.

Controller: A computer control system that interprets CNC codes and sends signals to the motor and spindle.

CNC routers have the following advantages:

Precision: Can create highly detailed and accurate cutting and design.

Repeatability: Once programmed, the same workpiece can be produced repeatedly.

Efficiency: They can quickly and efficiently complete complex tasks, reducing labor costs.

Automation: It can run unattended, freeing operators to perform other tasks.

CNC Router Machine require compatible CAD and CAM software to create design and generate tool paths. Popular software packages include AutoCAD, SolidWorks, RhinoCAM, and Vectric Aspire.

Weish CNC MASTER is a professional CNC machine manufacturer concentrating all its resources on developing and building CNC 5 axis gantry milling machine, CNC boring mill,router machine and CNC vertical lathe with C axis. Ever since its early days, Weish CNC has operated with “elitism ” as its business philosophy, focusing upon efficient management of human resources.