Introduction

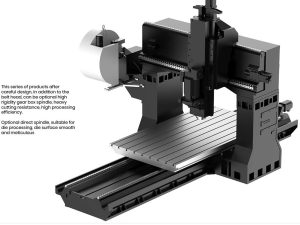

CNC boring mills are essential in precision machining, especially for applications requiring accurate hole dimensions and alignment in large and heavy workpieces. As a leading CNC machine manufacturer, Weish CNC focuses on providing advanced machining solutions, including the development of sophisticated toolpath strategies for CNC boring mills. This article explores advanced toolpath strategies that enhance the efficiency, precision, and overall performance of CNC boring mills.

Understanding CNC Boring Mills

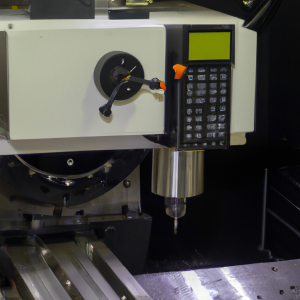

What is a CNC Boring Mill?

A CNC boring mill is a machine tool designed for enlarging existing holes with high precision. It uses boring heads to achieve the desired diameter and depth, ensuring tight tolerances and smooth finishes. These machines are crucial in industries such as aerospace, automotive, heavy equipment manufacturing, and industrial machinery.

Key Features

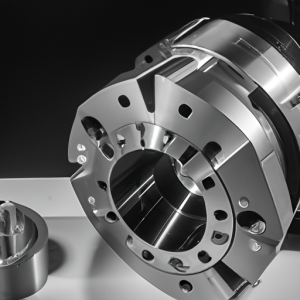

- High Precision: Capable of achieving tight tolerances and excellent surface finishes.

- Stability: Robust construction allows for machining large and heavy workpieces.

- Versatility: Suitable for various materials and complex geometries.

- Depth Control: Excellent for deep hole boring with consistent results.

Advanced Toolpath Strategies

Helical Interpolation

What is Helical Interpolation?

Helical interpolation is a toolpath strategy where the cutting tool moves in a helical path to machine holes. This technique allows for efficient and precise boring operations, especially in deep hole applications.

Benefits

- Improved Chip Evacuation: The helical motion helps in better chip removal, reducing the risk of chip clogging.

- Enhanced Surface Finish: Provides a smoother surface finish due to continuous cutting action.

- Reduced Tool Wear: Distributes cutting forces evenly, leading to longer tool life.

Spiral Boring

What is Spiral Boring?

Spiral boring involves moving the boring tool in a spiral pattern, gradually enlarging the hole. This method is effective for creating large-diameter holes with high precision.

Benefits

- High Precision: Achieves tight tolerances by gradually removing material.

- Efficient Material Removal: Maximizes material removal rates, enhancing productivity.

- Consistent Quality: Ensures uniform hole dimensions and alignment.

Zigzag Toolpath

What is Zigzag Toolpath?

The zigzag toolpath strategy involves moving the cutting tool in a back-and-forth zigzag pattern. This approach is useful for roughing operations and pre-finishing large holes.

Benefits

- Efficient Roughing: Quickly removes large amounts of material, preparing the workpiece for finishing.

- Flexibility: Can be adapted for various hole sizes and shapes.

- Reduced Machining Time: Enhances productivity by reducing the number of passes required.

Radial Toolpath

What is Radial Toolpath?

Radial toolpath strategy involves moving the cutting tool radially outward from the center of the hole. This method is effective for both roughing and finishing operations.

Benefits

- Improved Accuracy: Maintains tight tolerances throughout the machining process.

- Enhanced Surface Finish: Provides a smooth surface finish, particularly in finishing operations.

- Versatility: Suitable for various hole diameters and depths.

Adaptive Clearing

What is Adaptive Clearing?

Adaptive clearing is an advanced toolpath strategy that adjusts the cutting tool’s feed rate and path based on real-time cutting conditions. This approach optimizes material removal while minimizing tool wear.

Benefits

- Optimized Cutting Conditions: Adjusts feed rates to maintain optimal cutting conditions, reducing tool wear.

- High Efficiency: Maximizes material removal rates, enhancing overall productivity.

- Consistent Quality: Ensures uniform hole dimensions and surface finishes.

Implementation and Best Practices

Tool Selection

Choosing the right tools for boring operations is crucial. High-speed steel and carbide tools are commonly used due to their durability and cutting efficiency. Proper tool selection ensures optimal performance and longevity.

Machine Calibration

Ensuring that the CNC boring mill is properly calibrated is essential for achieving high precision. Regular maintenance and calibration checks help maintain machine accuracy and reliability.

Coolant and Lubrication

Using appropriate coolants and lubricants during boring operations helps reduce heat buildup, minimize tool wear, and improve surface finishes. Proper coolant management enhances overall machining performance.

Operator Training

Skilled operators are vital for implementing advanced toolpath strategies effectively. Regular training and upskilling ensure that operators are familiar with the latest techniques and technologies.

Conclusion

Advanced toolpath strategies for CNC boring mills significantly enhance the efficiency, precision, and overall performance of machining operations. As a premier CNC machine manufacturer, Weish CNC is committed to providing cutting-edge solutions that meet the diverse needs of various industries.

By implementing strategies such as helical interpolation, spiral boring, zigzag toolpaths, radial toolpaths, and adaptive clearing, businesses can achieve superior results with improved productivity and reduced costs. Contact Weish CNC today to learn more about our advanced machining solutions and discover how our expertise can help you achieve your manufacturing goals. Experience the quality and innovation that only a leading CNC machine manufacturer from China can offer.